Portable pressure testing system having in situ observation and continuously testing functions

A test system and test function technology, applied in the direction of testing material hardness, using stable tension/pressure to test material strength, measuring device, etc. problems, to improve the test efficiency and test accuracy, to achieve the effect of in-situ observation and continuous testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

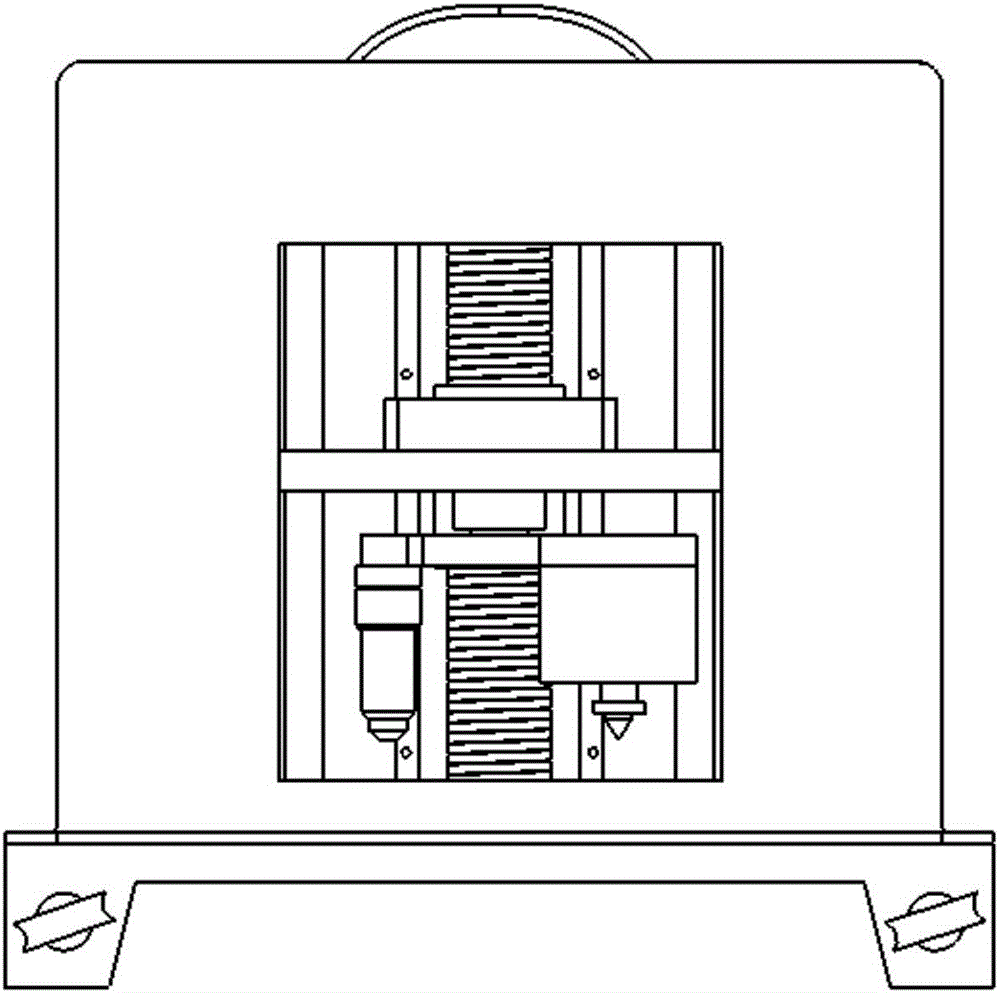

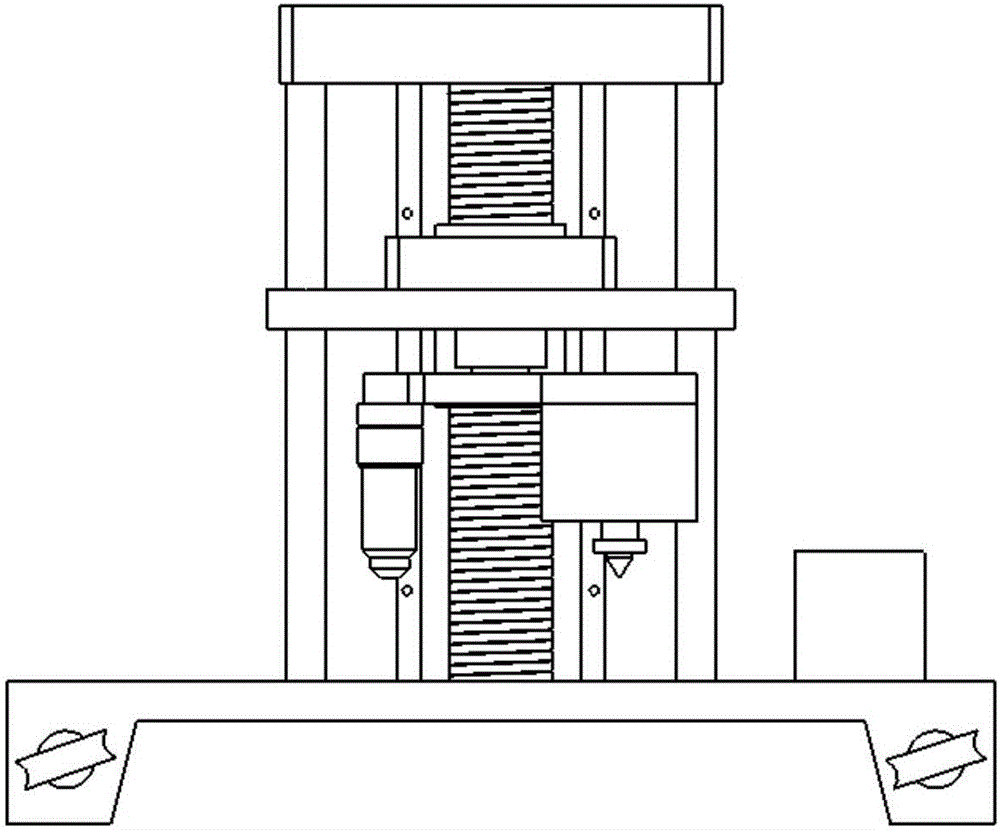

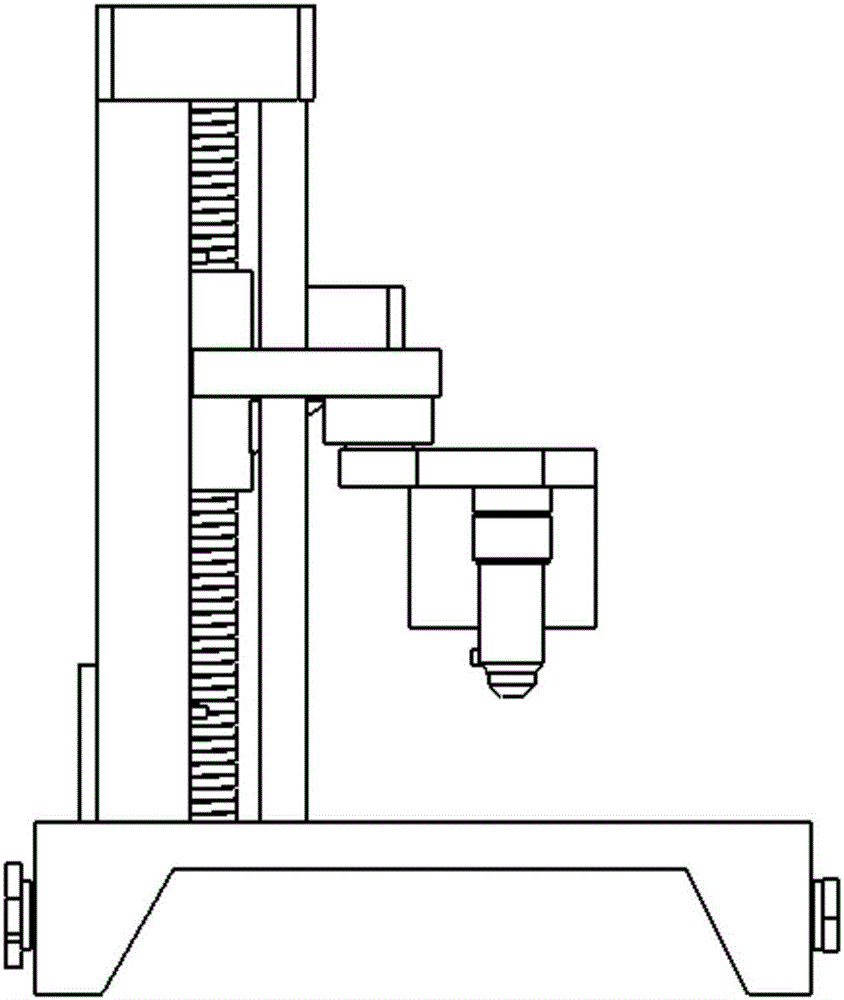

[0023] refer to Figure 1 to Figure 6 , a portable indentation test system with in-situ observation and continuous test functions includes a host test system and a computer system. The host test system includes a working platform adjustment module, a press-in test module, an in-situ observation module and an installation and fixing module. The working platform adjustment module includes a working platform and a working platform lifting adjustment assembly. The working platform and the working platform The lifting adjustment component is connected. The in-situ observation module and the press-in test module are coaxially installed on the turntable of the working platform at a fixed angle relative to each other. The turntable is used to drive the turntable to rotate at a fixed angle to switch between the press-in mode and the observation mode. The switching drive assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com