Method for detecting adverse state of inclined sleeve part screws of high-speed train overhead line system

A technology of sleeve parts and bad states, applied in computer parts, measuring devices, instruments, etc., can solve the problems of complex images and difficult fault detection, and achieve high correct detection rate, simple and effective state detection, and simplified difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

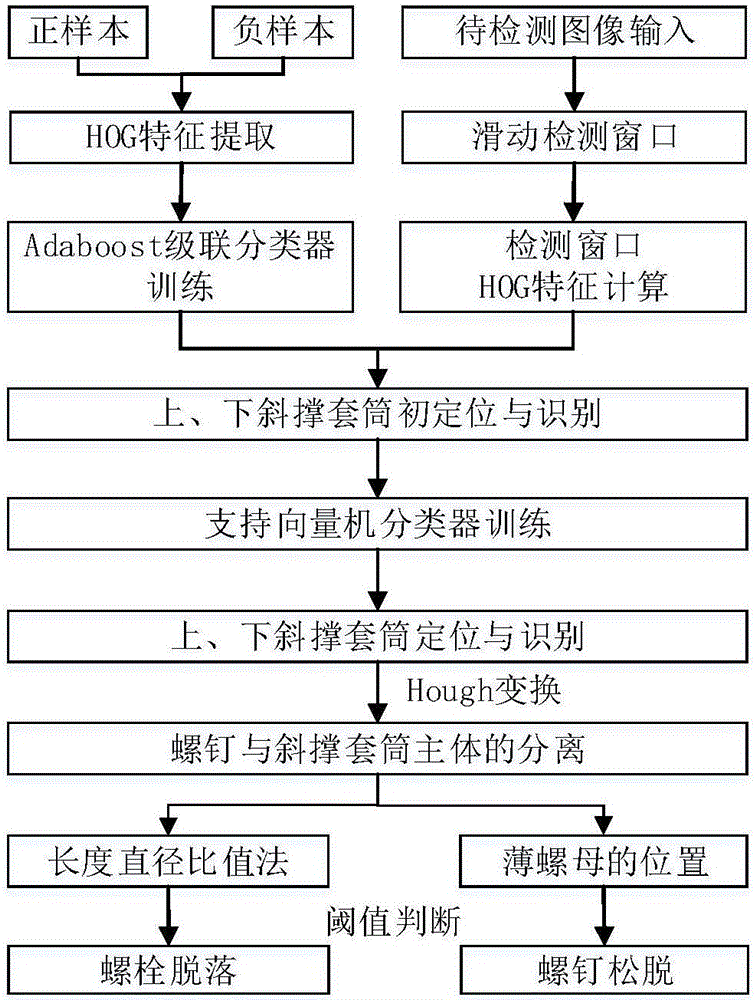

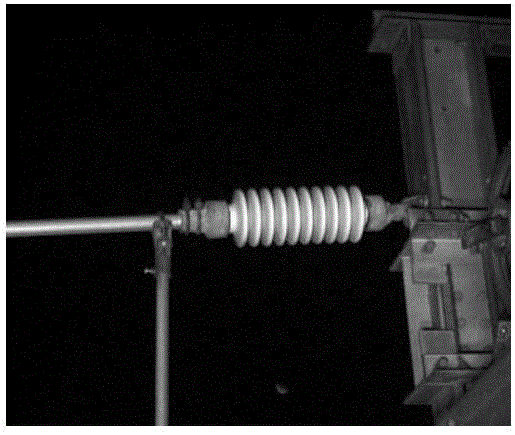

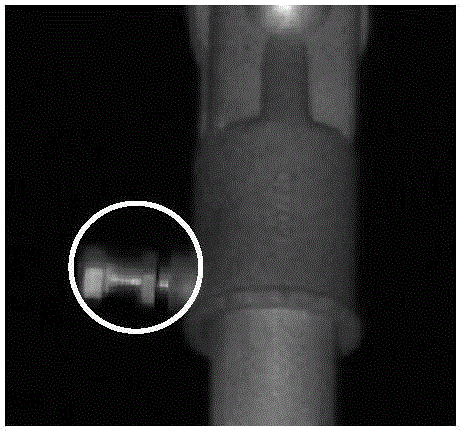

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. figure 1 It is a process block diagram of the method of the present invention. Figure 2 to Figure 5 It shows the position of the brace sleeve screw in the image collected on site, highlighting that it is difficult to detect such a small part. The details are as follows:

[0055] 1. Positioning and extraction of the brace sleeve

[0056] 1) The feature operator is invariant to image scaling, rotation and brightness changes. Since cell units may be repeated between adjacent blocks, an image with a resolution of 64×64 contains 7×7 blocks. The feature vectors of all blocks in the image are connected together to obtain the HOG feature vector of the entire image, and the final HOG feature descriptor contains 1764 vectors to form dimensions.

[0057] The value of any point (x, y) in the integral map is defined as the sum of the gray value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com