Transformer body structure of oil immersion type power distribution transformer

A distribution transformer, oil-immersed technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the problem that the mechanical strength of the winding cannot be guaranteed, the winding Problems such as low mechanical strength and poor short-circuit resistance can achieve the effect of reducing the amount of main materials, improving short-circuit resistance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

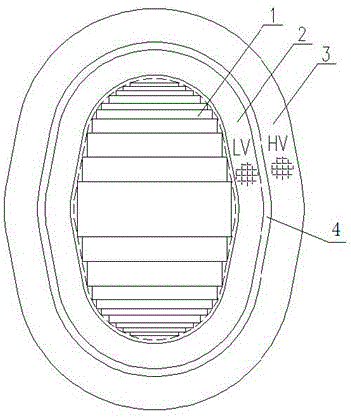

[0026] The oval body structure of the oil-immersed distribution transformer of the present invention, such as figure 1 As shown, it includes iron core 1 , low voltage winding 2 , high voltage winding 3 and insulating structure 4 . The core 1 is a three-phase three-column core, and the three-phase high-voltage winding 3 and low-voltage winding 2 adopt a wrap-around structure, which are respectively set on the three columns of the core 1, and there is a support plate between the low-voltage winding 2 and the core 1. The insulating structure 4 is supported between the iron core and the winding, and plays the roles of supporting, insulating and providing a heat dissipation oil circuit. The shape and size of the insulating structural member 4 cooperate with the iron core, high-voltage winding and low-voltage winding, so that the body forms a strong overall structure.

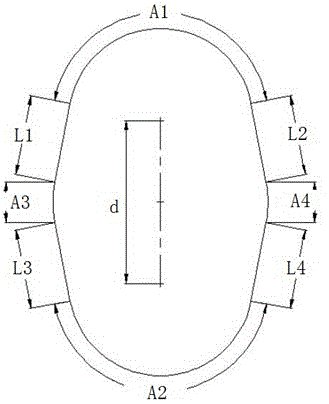

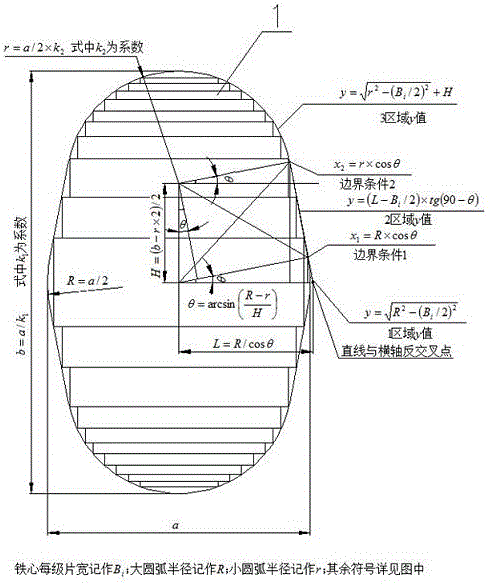

[0027] The cross-sections of the coil bodies of the low-voltage winding 2 and the high-voltage winding 3 are oval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com