Printed circuit board and fabrication method thereof

A manufacturing method and circuit board technology, applied in the directions of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of easy occurrence of voids, hidden functional dangers of circuit boards, and increased costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

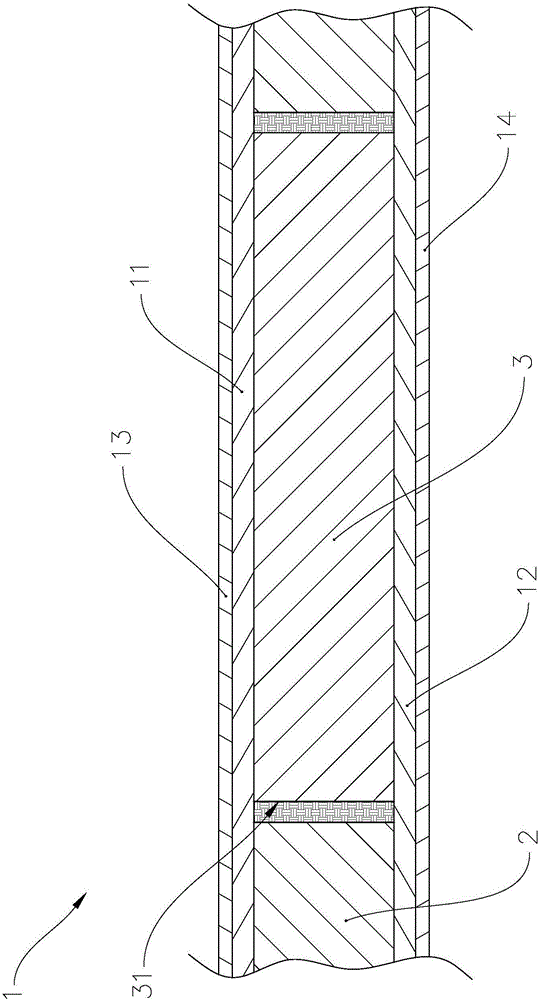

[0038] Example of a circuit board:

[0039] refer to figure 1 , figure 1 It is a cross-sectional schematic diagram of a circuit board semi-finished product in an embodiment of a circuit board manufacturing method of the present invention. The circuit board 1 includes a metal substrate 2, an insulating layer 11 disposed above the metal substrate 2, an insulating layer 12 disposed below the metal substrate 2, a copper foil layer 13 disposed above the insulating layer 11, and a copper foil layer disposed below the insulating layer 12. Foil layer 14. An insulating block 3 is placed in the through hole of the metal substrate 2 .

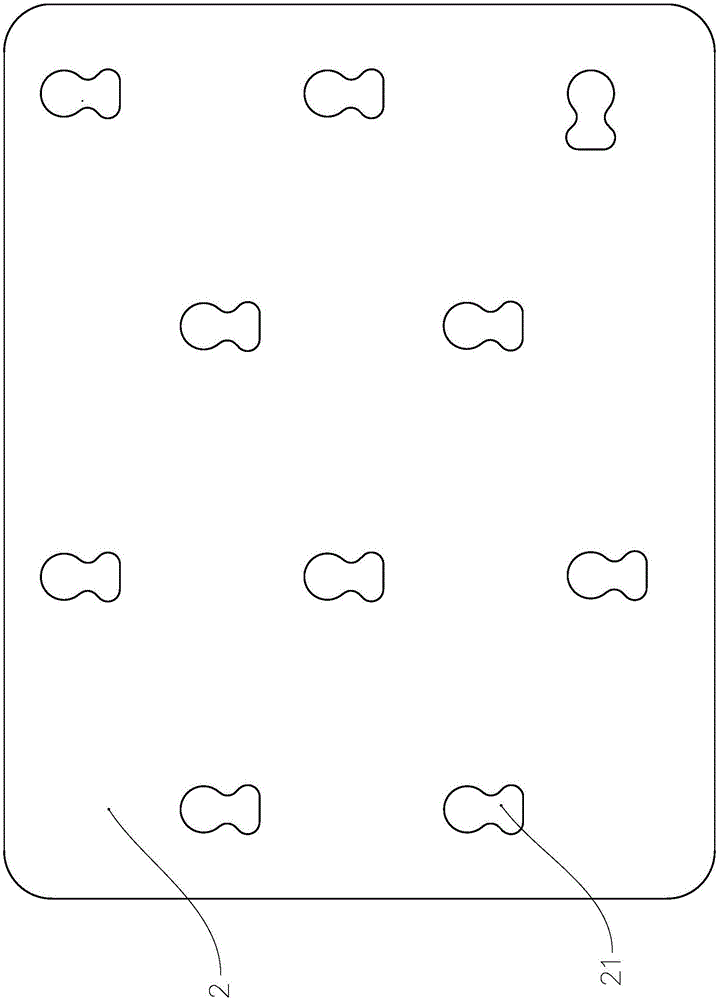

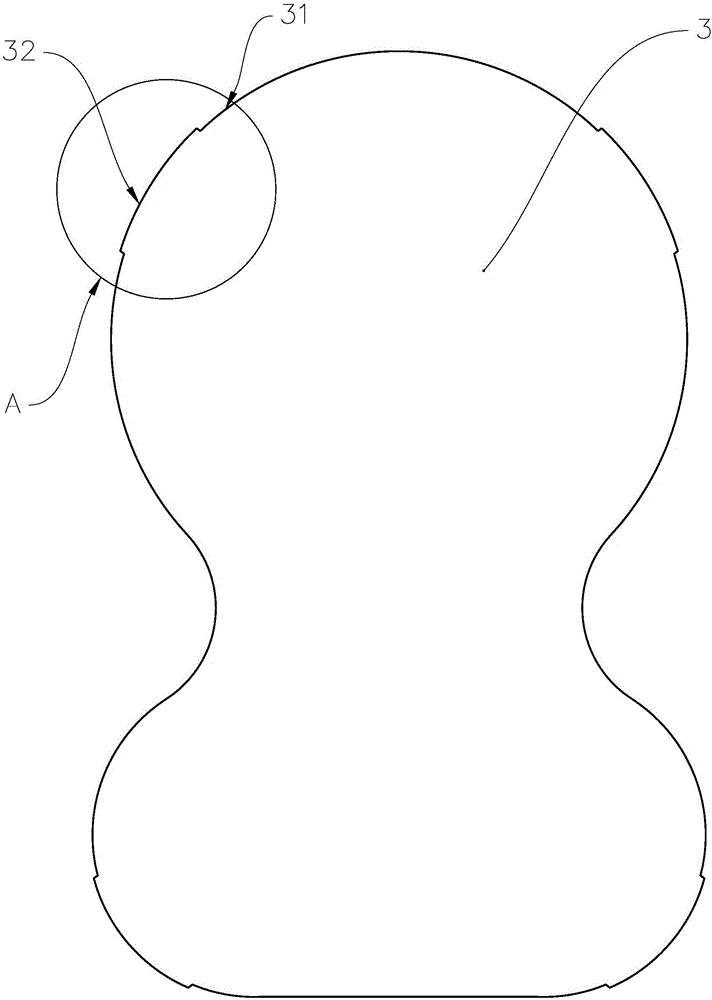

[0040] refer to figure 2 , figure 2 It is a structural schematic diagram of a metal substrate in an embodiment of a method for manufacturing a circuit board of the present invention. combine figure 1 , the metal substrate 2 can be made of copper, aluminum or other metal substrates, and one or more through holes 21 are arranged on the metal substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com