injection mold

A technology for injection molds and molds, applied in the field of injection molding equipment, can solve the problems affecting the quality of injection molding, waste of melt materials, and inability to ventilate smoothly, so as to prevent excessive cavity pressure, avoid material waste, and eliminate potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

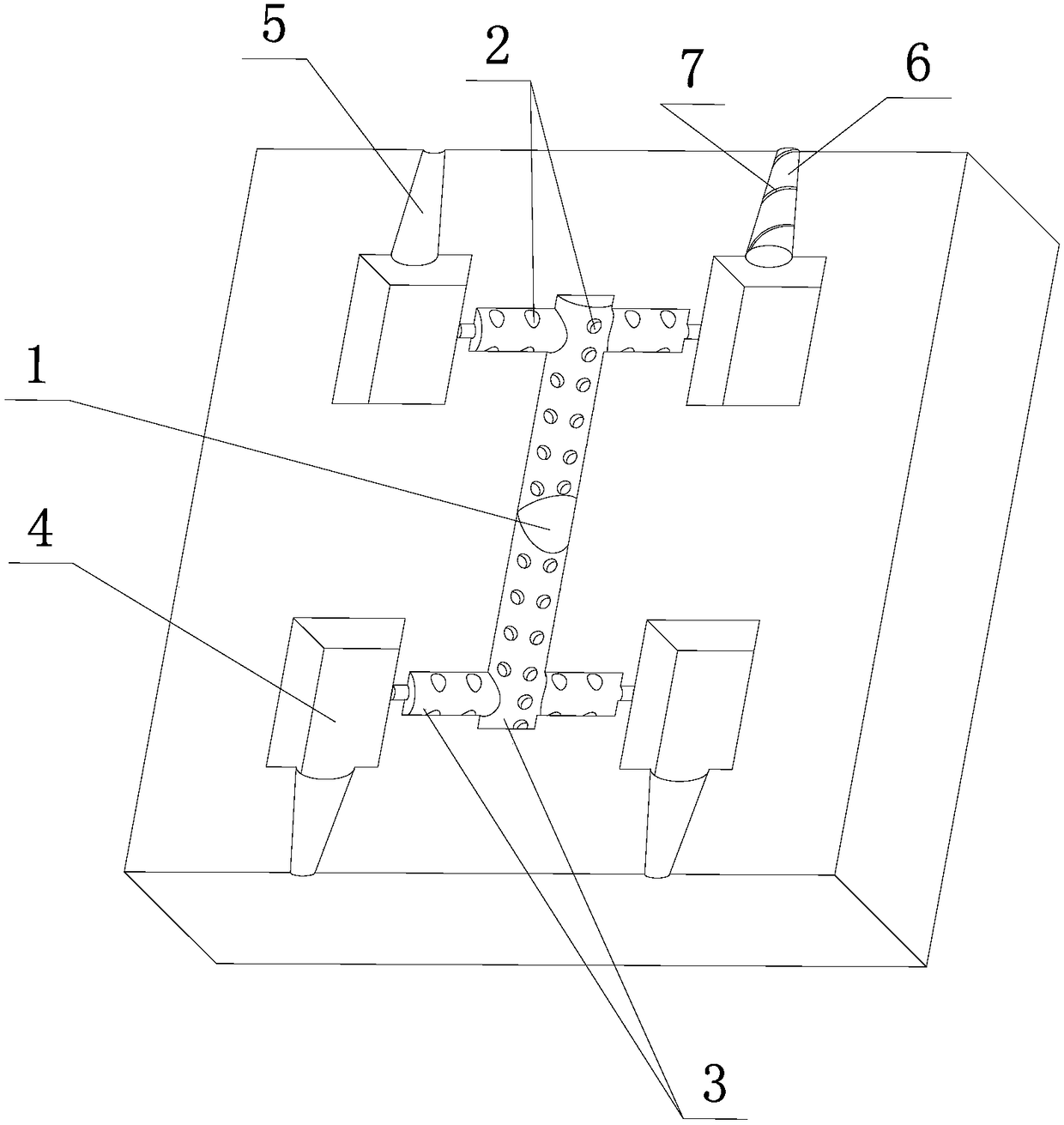

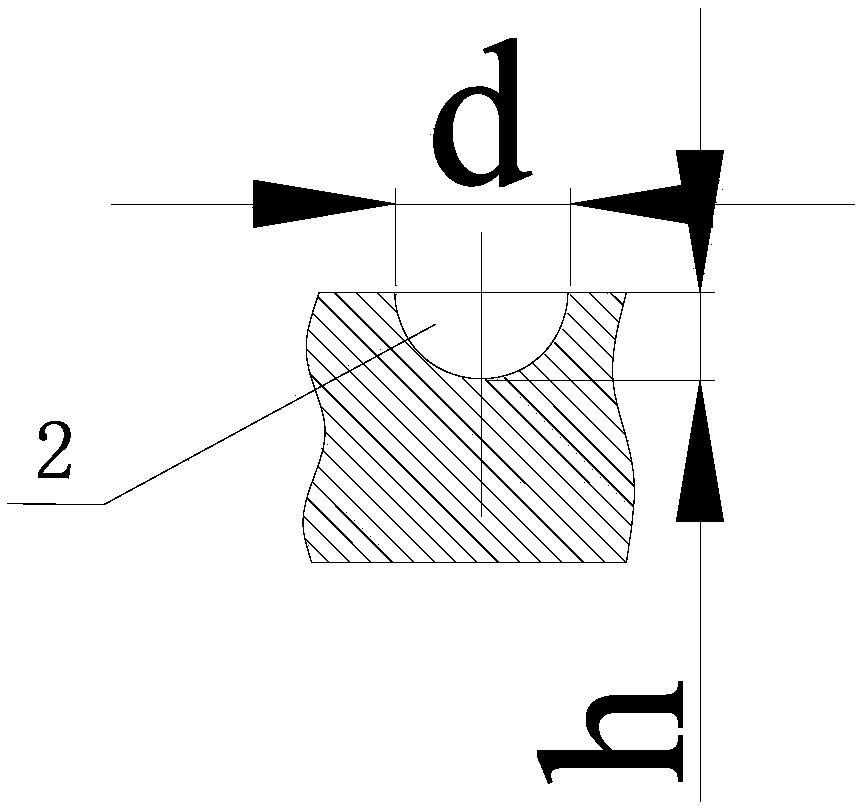

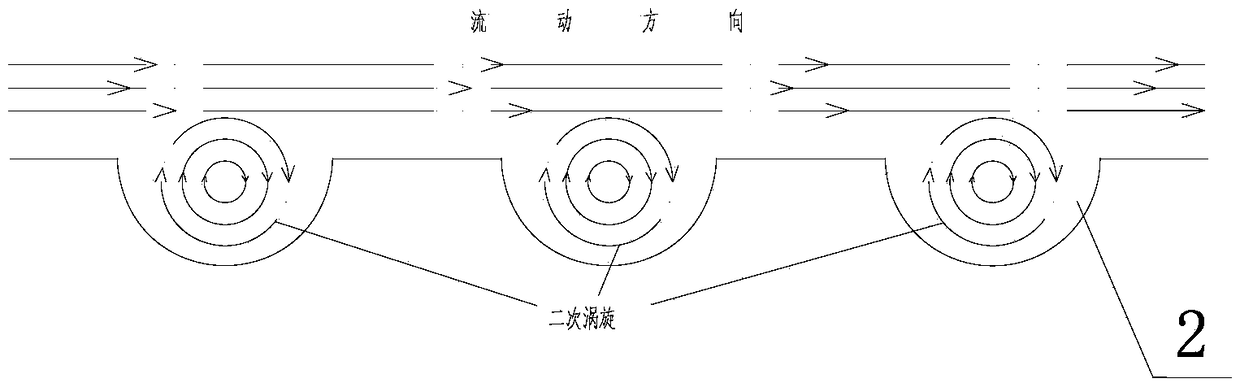

[0016] like figure 1 , figure 2 , image 3 As shown, the injection mold of the present invention is assembled by two sub-moulds. The interior of the mold is provided with a main runner 1, a sub-runner 3 and a cavity 4 which are connected in sequence. The runner walls of the main runner 1 and the sub-runner 3 are evenly distributed with a plurality of circular pits 2 .

[0017] Each sub-mold of the mold is provided with a plurality of arc-shaped grooves 5 corresponding to the cavity 4, and the two arc-shaped grooves 5 at the corresponding positions of the two sub-molds are combined to form a complete gradually decreasing radius from the inside to the outside. Round holes, each tapered round hole is tightly fitted with a circular frustum 6 whose shape matches the tapered circular hole, and the side of the circular frustum 6 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com