Method for constructing high-temperature plastic flow densification constitutive models of powder sintering materials

A technology of sintered materials and constitutive models, applied in design optimization/simulation, special data processing applications, instruments, etc., to achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Prediction of flow stress and instantaneous density and stability analysis of FC0205 powder sintered alloy steel during thermal processing. For powder sintered alloy steel samples with typical components for powder metallurgy parts, combined with thermodynamic calculations and thermal processing conditions, the range of thermal processing parameters is obtained: processing temperature 850-1000 ° C; processing strain rate 0.01-10s -1 , design the thermal simulation experiment as follows:

[0068] Initial sintering density 0.80; deformation temperature (°C): 850, 900, 950, 1000; strain rate (s -1 ): 0.01, 0.1, 1.0, 10.

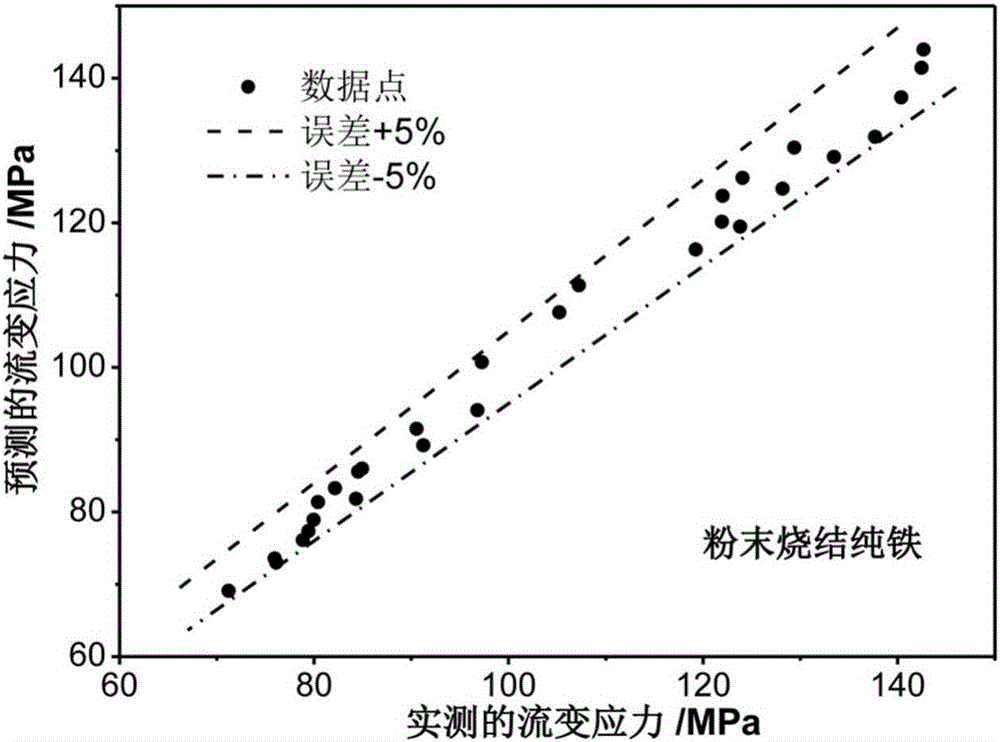

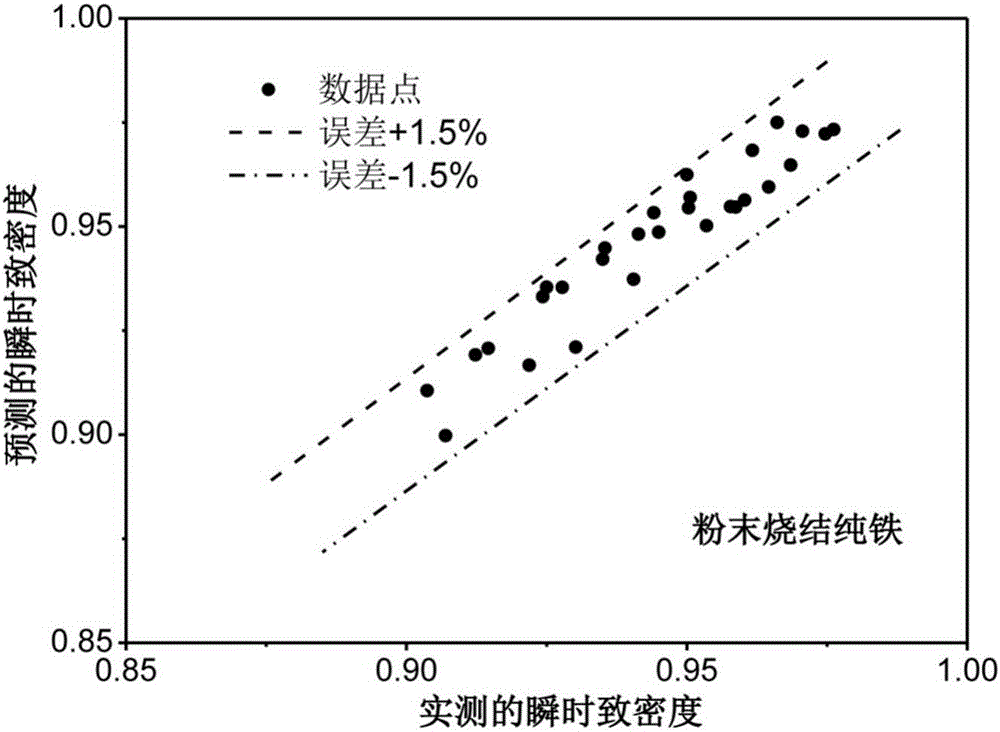

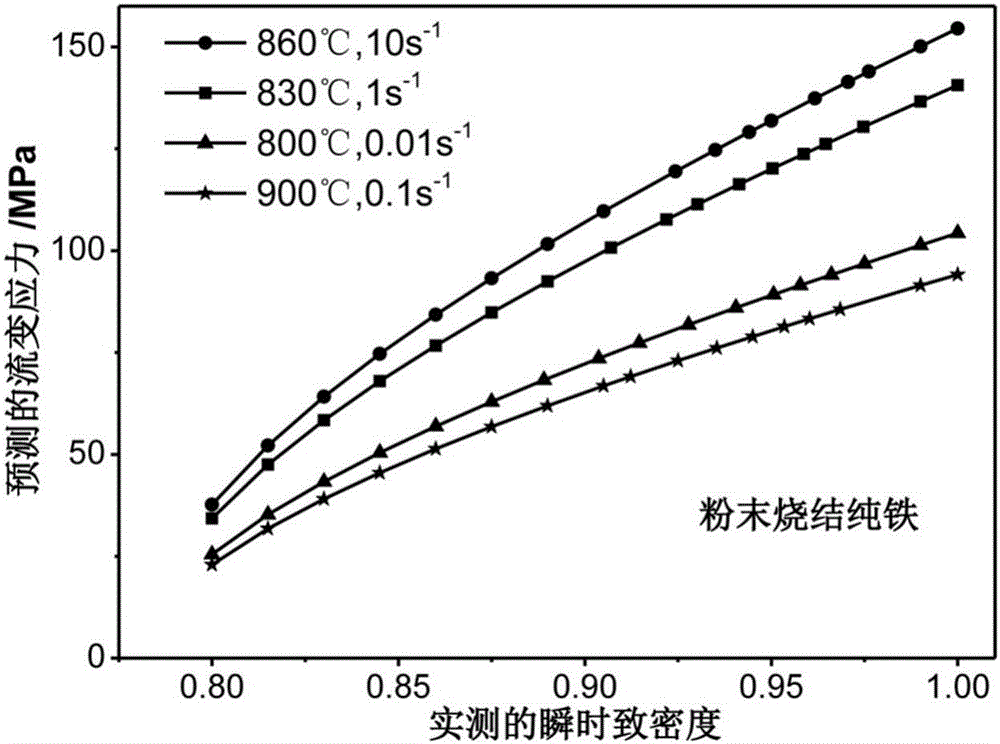

[0069] The experimental results were processed according to the above constitutive model, and the material characteristic parameters of the constitutive model for high temperature plastic rheological densification of FC0205 powder sintered alloy steel were obtained (see Table 1). By substituting the material characteristic parameters in Table 1 into the...

Embodiment 2

[0073] Prediction of flow stress and instantaneous density and stability analysis of F0005 powder sintered steel during thermal processing. For the powder sintered steel sample with typical components for powder metallurgy parts, combined with thermodynamic calculations and thermal processing conditions, the range of thermal processing parameters is obtained: processing temperature 850-950°C; processing strain rate 0.01-10s -1 , design the thermal simulation experiment as follows:

[0074] Initial sintering density 0.80; deformation temperature (℃): 850,880,910,940; strain rate (s -1 ): 0.01, 0.1, 1.0, 10.

[0075] The experimental results were processed according to the above constitutive model, and the material characteristic parameters of the constitutive model for high temperature plastic rheological densification of F0005 powder sintered steel were obtained (see Table 2). By substituting the material characteristic parameters in Table 2 into the nonlinear constitutive r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com