A Calculation Method for Multiple Fluid-Structure Interactions of Stern Bearing-Rotor System

A technology of fluid-structure coupling and calculation method, applied in the direction of calculation, design optimization/simulation, instrument, etc., can solve the problems of low calculation accuracy of fluid domain, inaccurate numerical simulation, weak independent design force, etc., to overcome grid distortion The effect of being too large, simplifying subsequent calculation steps, and saving subsequent computing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

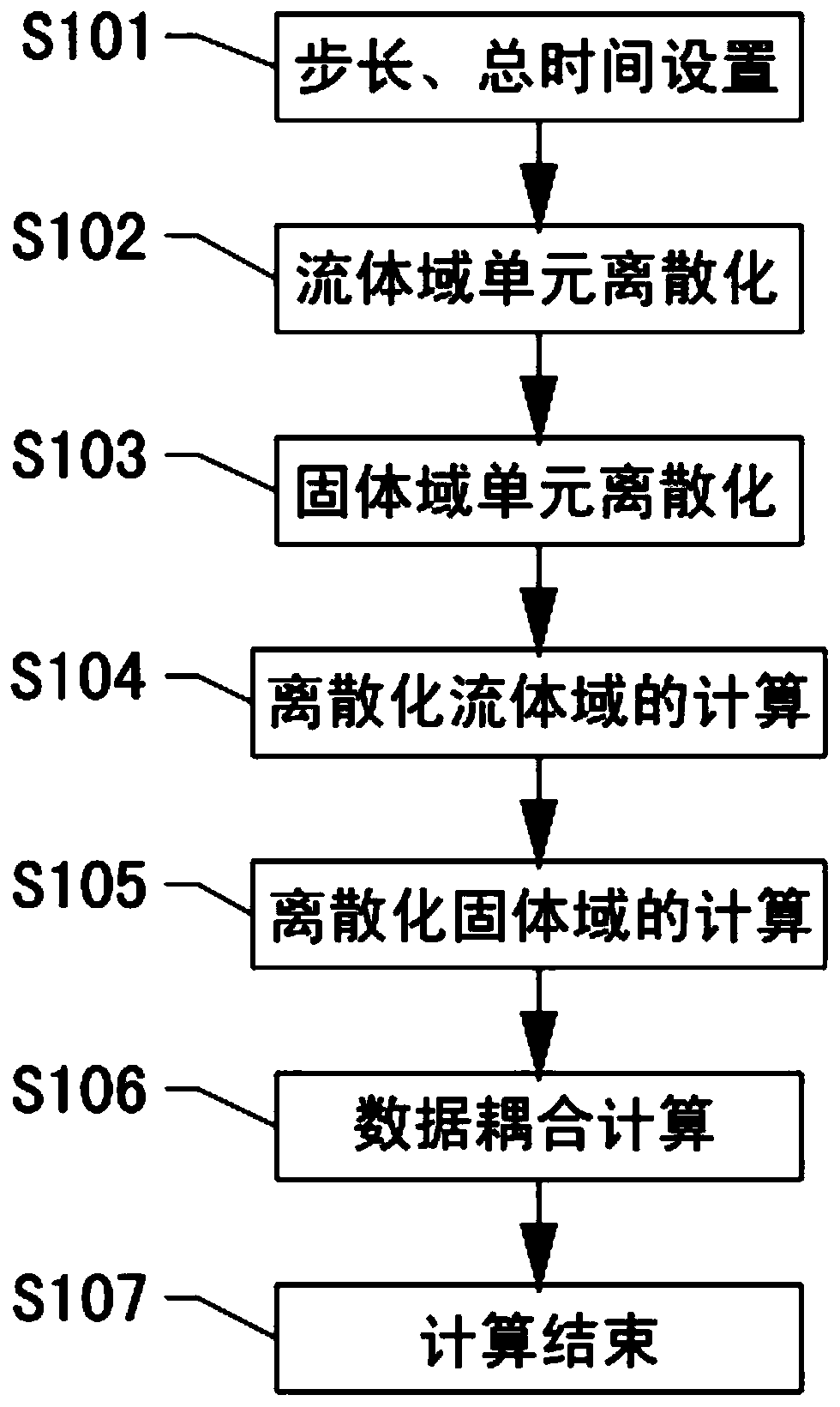

[0118] Embodiment 1: The multiple fluid-solid coupling calculation process of two four-blade tail bearing-rotor systems is the best embodiment of the present invention.

[0119] 1.1, set the unit time step Δt 1 , the total time to calculate T 1 ;

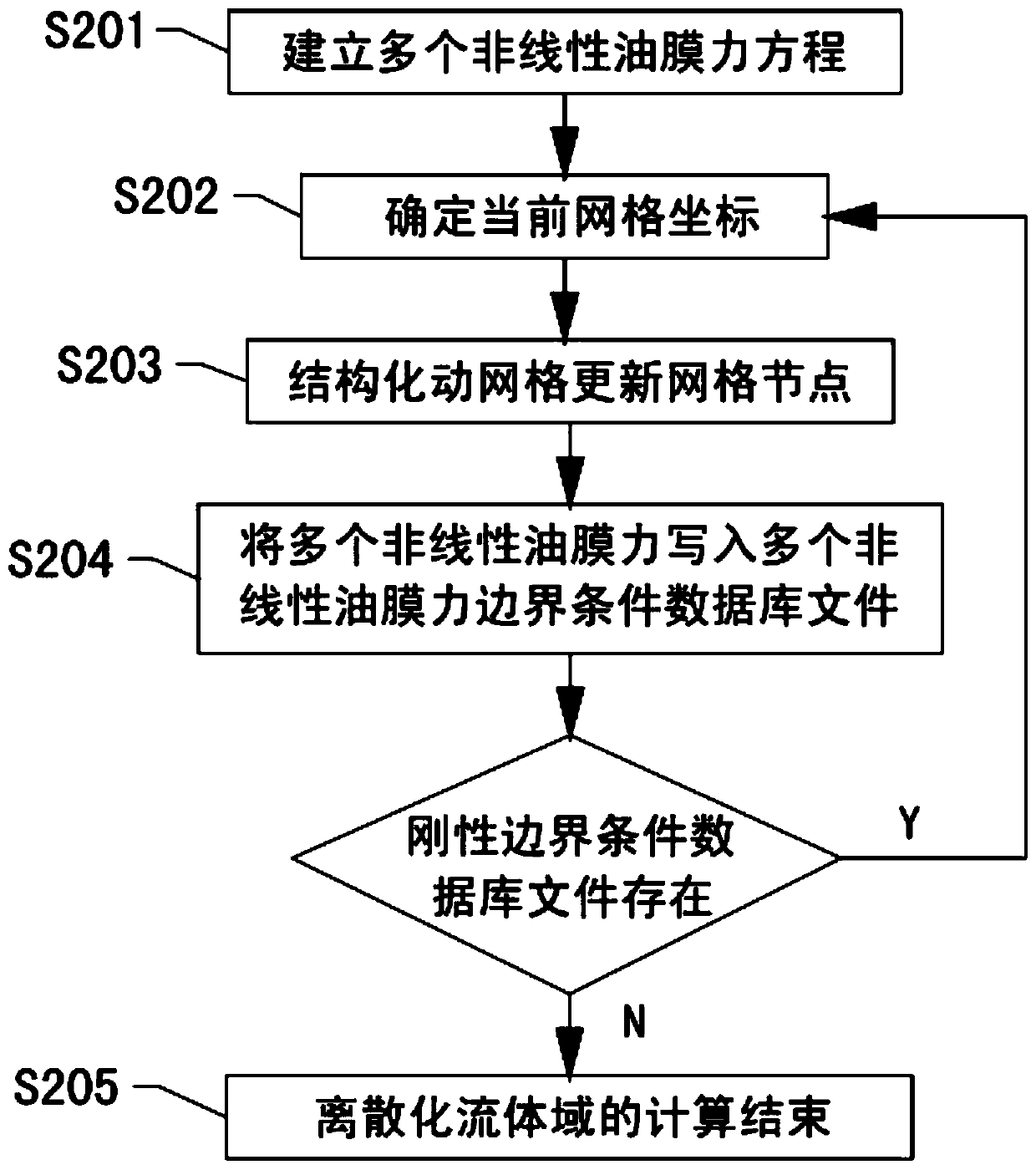

[0120] 1.2. Using computational fluid dynamics (CFD) software, the numerical calculation of two four-lobe tail bearings is carried out at the same time, and the nonlinear oil film force (Fx 1 , Fy 1 ), (Fx 2 , Fy 2 );

[0121] 1.3, the Δt 1 , the current calculation time T d1 , (Fx 1 , Fy 1 ), (Fx 2 , Fy 2 ) is written into two four-blade tail bearing boundary condition database files as the nonlinear oil film force boundary condition calculated in the discretized solid domain;

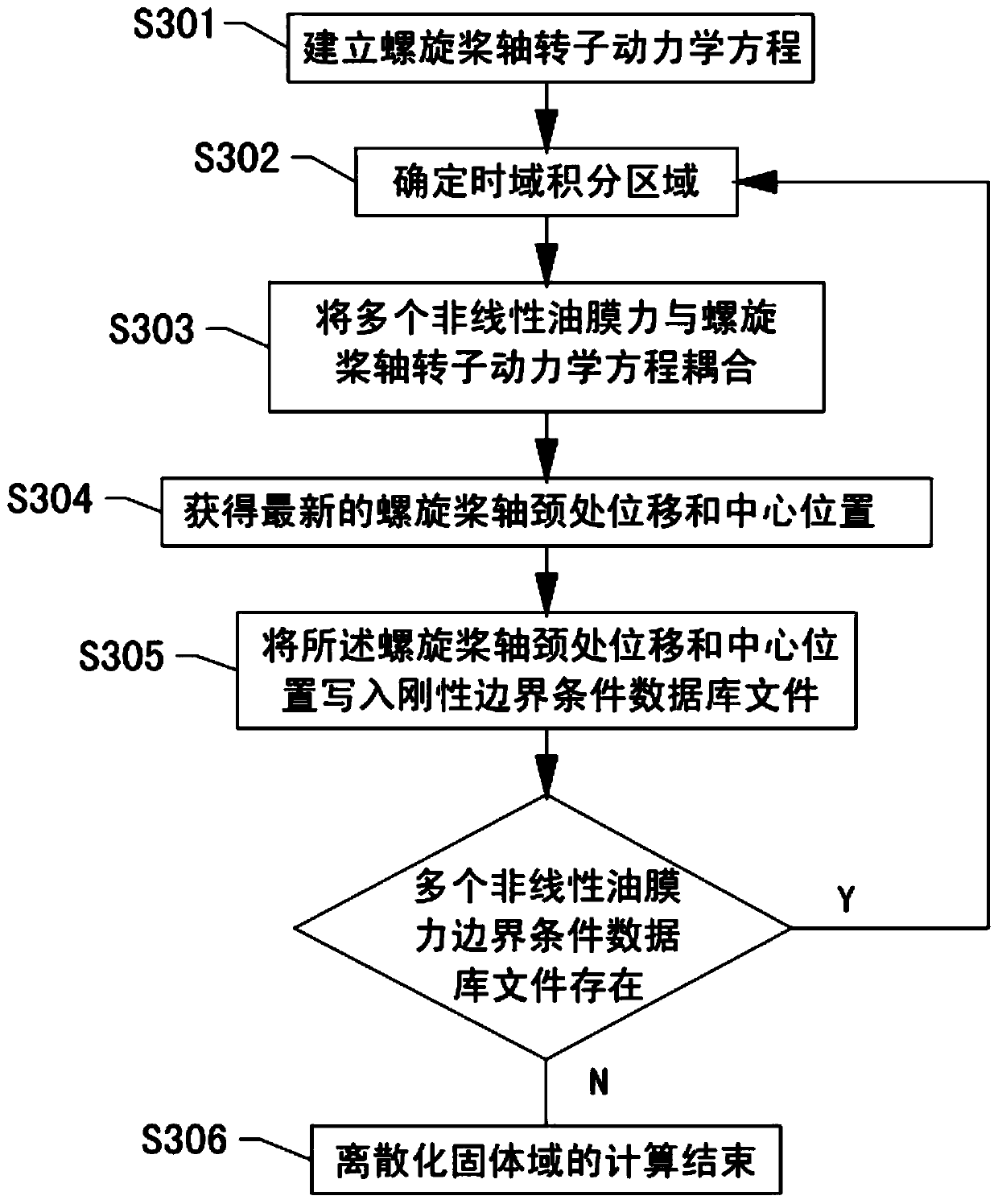

[0122] 1.4, discretized solid domain calculation to establish propeller shaft rotor dynamics equation:

[0123]

[0124] Among them, M is the mass matrix of the propeller shaft rotor system, s is the displacement of the propeller shaft rotor...

Embodiment 2

[0162] Embodiment 2: Multiple fluid-solid coupling calculation process of the three elliptical stern bearing-rotor system.

[0163] 2.1, set the unit time step Δt 2 , the total time to calculate T 2 ;

[0164] 2.2. Using computational fluid dynamics CFD software, numerical calculations are carried out on three elliptical tail bearings at the same time, and the nonlinear oil film force (Fx 5 , Fy 5 ), (Fx 6 , Fy 6 ), (Fx 7 , Fy 7 );

[0165] 2.3, the Δt 2 , the current calculation time T d2 , (Fx 5 , Fy 5 ), (Fx 6 , Fy 6 ), (Fx 7 , Fy 7 ) is written into three elliptical stern bearing boundary condition database files as the nonlinear oil film force boundary condition calculated in the discretized solid domain;

[0166] 2.4, discretized solid domain calculation to establish propeller shaft rotor dynamics equation:

[0167]

[0168] 2.5, discretized solid domain calculation calls the above three elliptical stern bearing boundary condition database files to de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com