Containment filtering and discharging system capable of carrying out passive operation for a long term

An emission system and containment technology, used in nuclear power generation, radioactive purification, climate sustainability, etc., can solve the problem that the containment filtration and emission system cannot work for a long time, and reduce resuspension, increase dust holding capacity, reduce The effect of small initial loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

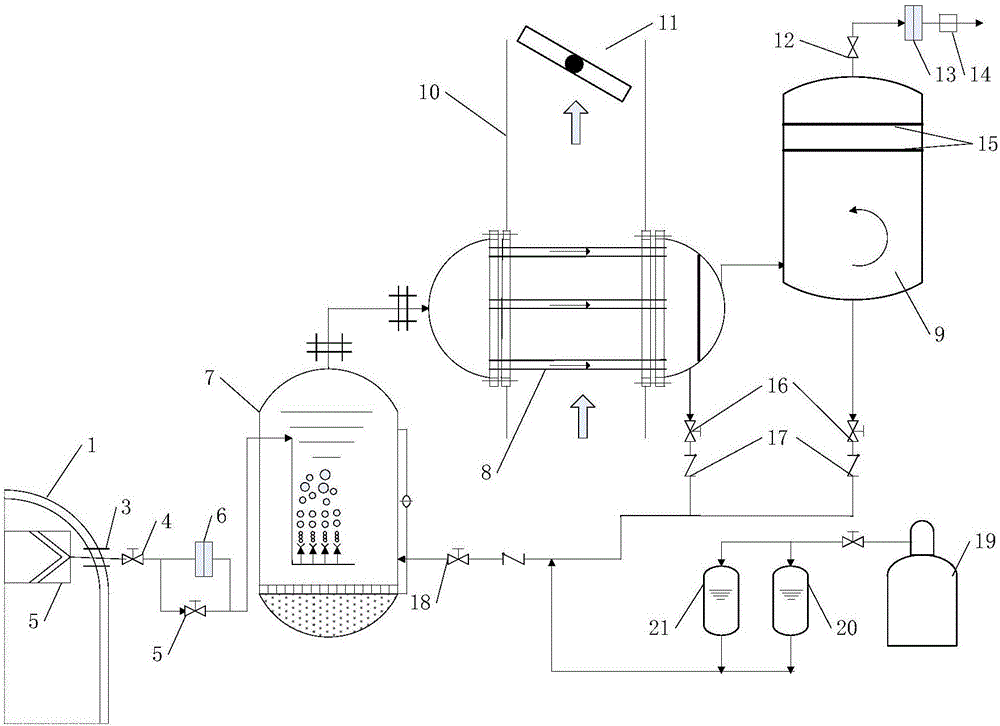

[0015] Such as figure 1 As shown, a long-term passive operation containment filtration and drainage system is composed of a pre-filter, a water washing filter, a water washing liquid recovery system, a chemical reagent addition system, and corresponding pipeline valves.

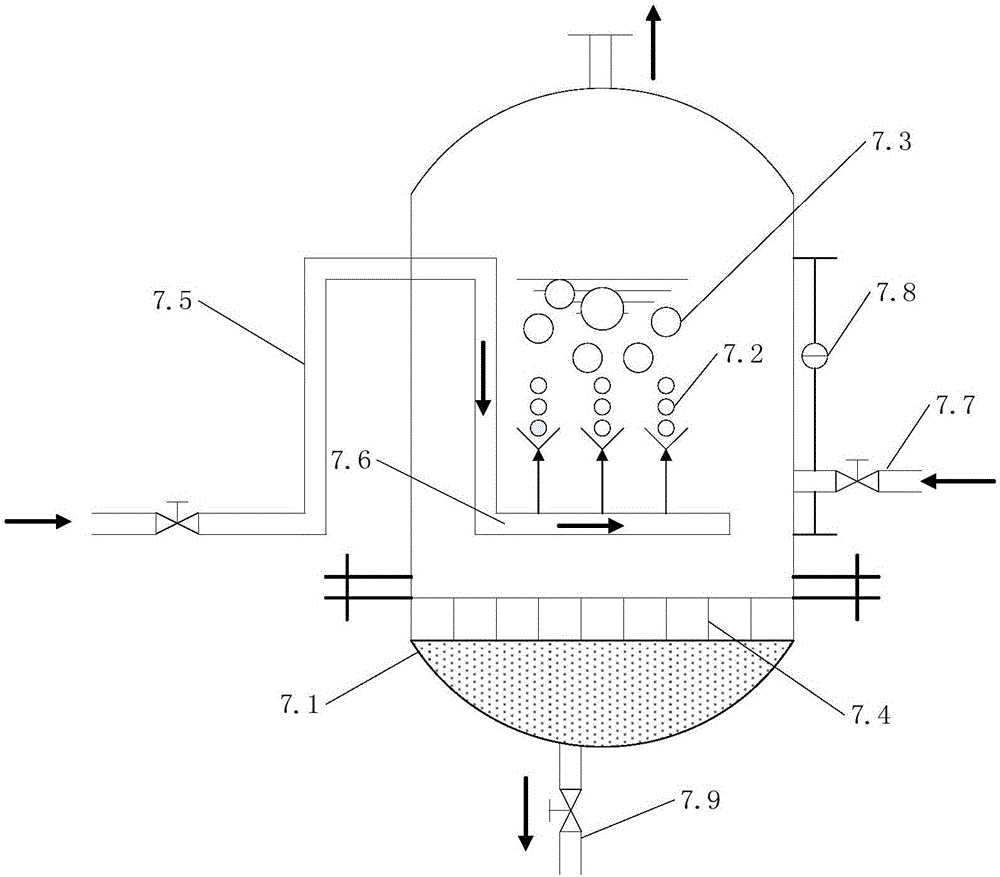

[0016] The pre-filter 2 is a fiber filter composed of coarse fibers, which is installed inside the containment 1, and is used for primary filtration of large-diameter aerosol particles in the exhaust gas, so that larger-particle aerosols can be retained In the containment, the number of aerosols entering the water-washing filter can be reduced, thereby reducing the accumulation of aerosol particles in the water-washing filter, effectively alleviating the resuspension of aerosols, and prolonging the service life of the system. The outlet of the pre-filter 2 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com