Fat and/or Oil Composition for Heat Cooking and Method of Preparing Same, and Method of Preventing Deterioration of Fat and/or Oil for Heat Cooking Caused by Heating

A kind of oil composition and oil technology, applied in the direction of edible oil/fat, application, food science, etc., can solve the problems of heavy burden, deterioration, bad influence on the flavor or appearance of fried cooking products, and improve operability and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036]

[0037]The fats and oils used in the preparation method of the oil and fat composition for cooking according to the present invention, like general fats and oils, can be obtained by using crude oil pressed from seeds or fruits of plants, or animal materials as a starting material, and refined by refining to be prepared; the refining process is followed by a degumming process, a deacidification process, and a decolorization process according to needs, and then a deodorization process after a dewaxing process according to needs. The aforementioned degumming step, deacidification step, and dewaxing step can be appropriately selected according to the quality of the crude oil, which varies depending on the oil raw material before oil recovery.

[0038] In the preparation method of the present invention, in addition to the above-mentioned oil refining process, it also includes adding an alkali metal soap of a saturated fatty acid with a carbon number of 4-16 to the refined ...

Embodiment

[0044] Hereinafter, although this invention is demonstrated concretely based on an Example, this invention is not limited to these Examples.

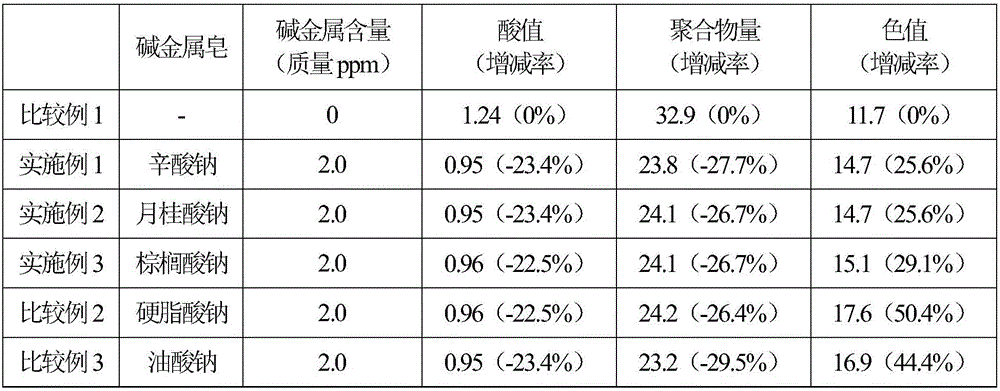

[0045] The sample oils of Examples and Comparative Examples were prepared in the formulations shown in Tables 1 and 2 below, and after a heating test, the acid value, polymer amount, and color value were evaluated. The preparation procedure of the sample oil, the procedure of the heating test, the evaluation method, and the results are as follows.

[0046]

[0047] As the oil and fat, Nisshin Canola Oil (manufactured by Nisshin Oliver Co., Ltd.) was used.

[0048] As alkali metal soaps of saturated fatty acids with a carbon number of 4-16, sodium caprylate (C8:0, "sodium n-octanoate" produced by Tokyo Chemical Industry Co., Ltd.), sodium laurate (C12:0, Tokyo Chemical Industry Co., Ltd. manufactured), sodium palmitate (C16:0, manufactured by Tokyo Chemical Industry Co., Ltd.).

[0049] As an alkali metal soap of a comparative exampl...

Embodiment 4

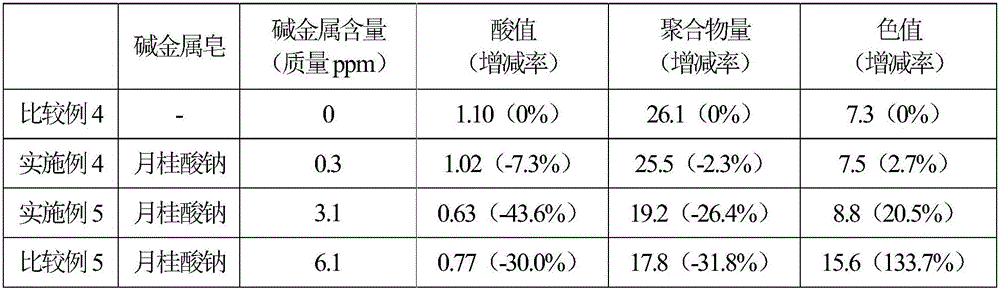

[0054] In embodiment 4-5 and comparative example 5, the alkali metal soap (sodium laurate) of the saturated fatty acid that carbon number is 12 is uniformly mixed in the oil, by atomic absorption spectrophotometer ("Z2310" Z2310 manufactured by Hitachi, Ltd. ”) to determine the alkali metal (sodium) content. The alkali metal content in the sample oil was 0.3 ppm by mass in Example 4, 3.1 ppm by mass in Example 5, and 6.1 ppm by mass in Comparative Example 5.

[0055]

[0056] 10.0 g of the prepared sample oil (Comparative Example 1-3, Example 1-3) was added to a test tube with a diameter of 20 mm and a length of 120 mm. The test tube to which the sample oil was added was heated at 185° C. for 32 hours with a heating block. The results of acid value, polymer amount and color value are shown in Table 1.

[0057]

[0058] 10.0 g of the prepared sample oil (Comparative Example 4-5, Example 4-5) was added to a test tube with a diameter of 30 mm and a length of 120 mm. The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com