Radar positive pressure drying method based on hydrophilic membrane

A drying method and technology of hydrophilic membrane, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as the application of positive pressure drying of radar equipment, and achieve small occupied space, good user experience, system low-complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

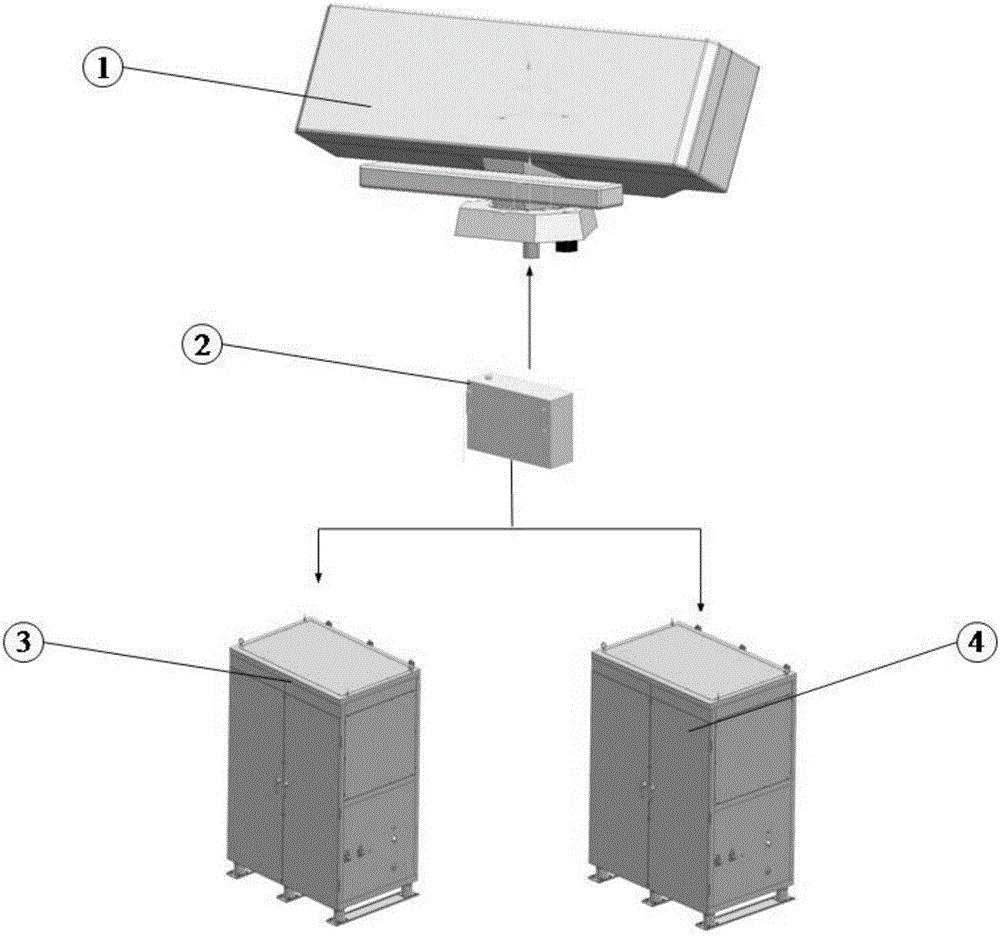

[0013] A kind of radar positive pressure drying method based on hydrophilic film of the present invention such as figure 1 shown. The positive pressure drying source provides one-way positive pressure drying air for the radar cabin and the cabinet. After the drying wind enters the antenna cabin and the cabinet, a positive pressure is generated inside the equipment to be dried. At the same time, the air volume missed by the drying equipment is directly discharged into the external environment atmosphere. Returning to the positive pressure drying source, the positive pressure drying source supplies one-way positive pressure air, and maintains the dynamic balance of pressure between the antenna cabin, the cabinet and the outside atmosphere by continuously supplementing the dry air.

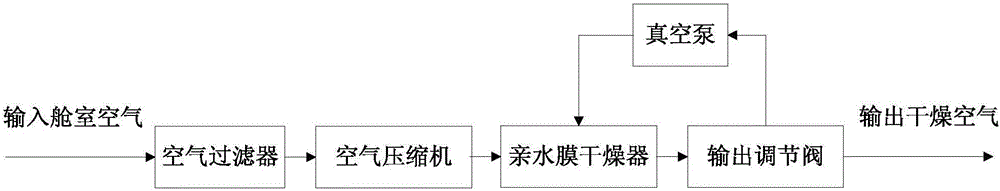

[0014] The positive pressure drying source directly extracts the air in the cabin, and after being filtered by the air filter, the air compressor is used to pressurize and send it into the drying fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com