A kind of micro reaction unit and micro reactor

A technology of micro-reactions and reactants, applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of small processing capacity, large pressure loss, and non-reaction channel parts Many problems, to achieve the effect of reducing the pressure drop of the reaction and enhancing the heat transfer of the fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

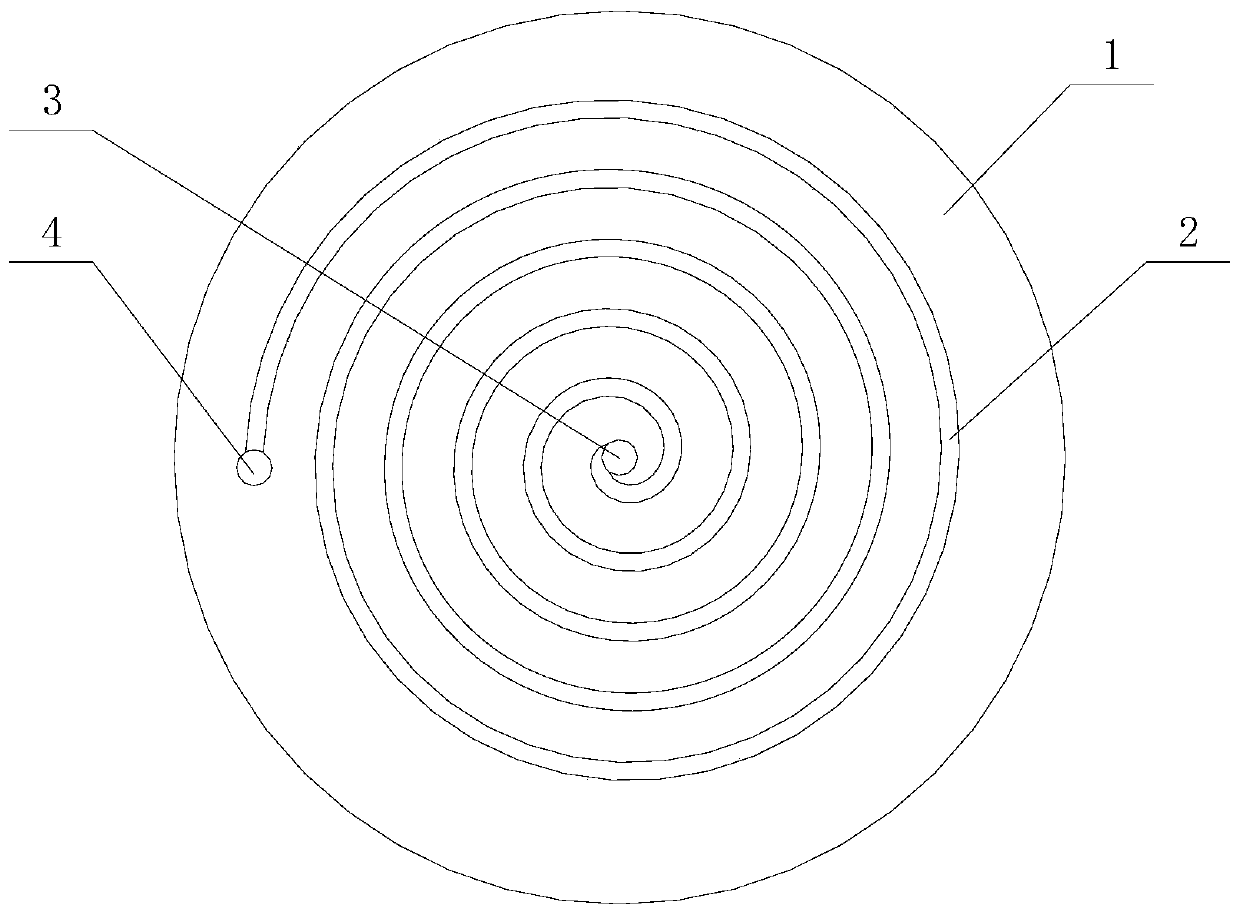

[0051] Such as figure 1As shown, the embodiment of the present invention provides a micro-reaction unit, including a body 1, the body 1 is a plate structure, the body 1 is provided with a reactant inlet 3 and a reactant outlet 4, a reactant inlet 3 and a reactant outlet 4 are connected through the reaction channel 2, and the reaction channel 2 is spirally coiled around the reactant inlet 3. Alternatively, the reaction channel 2 can also be spirally wound around the reactant outlet 4 .

[0052] In this embodiment, the structure of the reaction channel of the microreactor is improved, and a helical reaction channel structure is adopted to make the micro-reaction fluid form a helical shape, which is beneficial to the sufficient mixing of the reaction fluid.

[0053] Preferably, the body 1 of the plate-like structure includes opposite first and second end faces, and the reactant inlet 3 or the reactant outlet 4 has a centerline, and on the first end face or the second At least o...

Embodiment 2

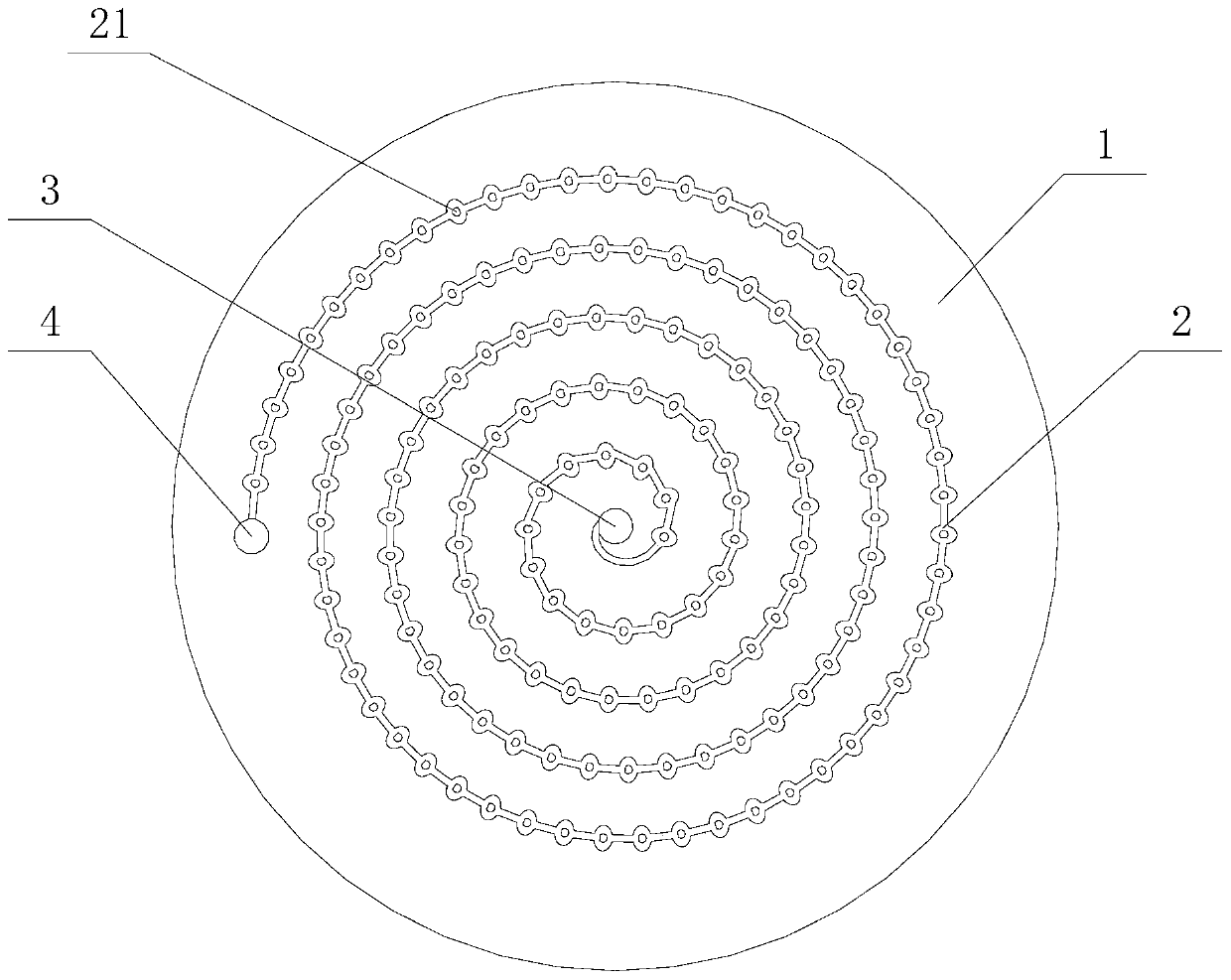

[0056] Preferably, it further includes a sealing plate 12 connected to the end surface of the body 1 having the first spiral groove. The first spiral groove on the body 1 is covered by the sealing plate 12 to form the reaction channel 2 . Such a structural design makes the end surface of the main body 1 and the sealing plate 12 bonded and connected.

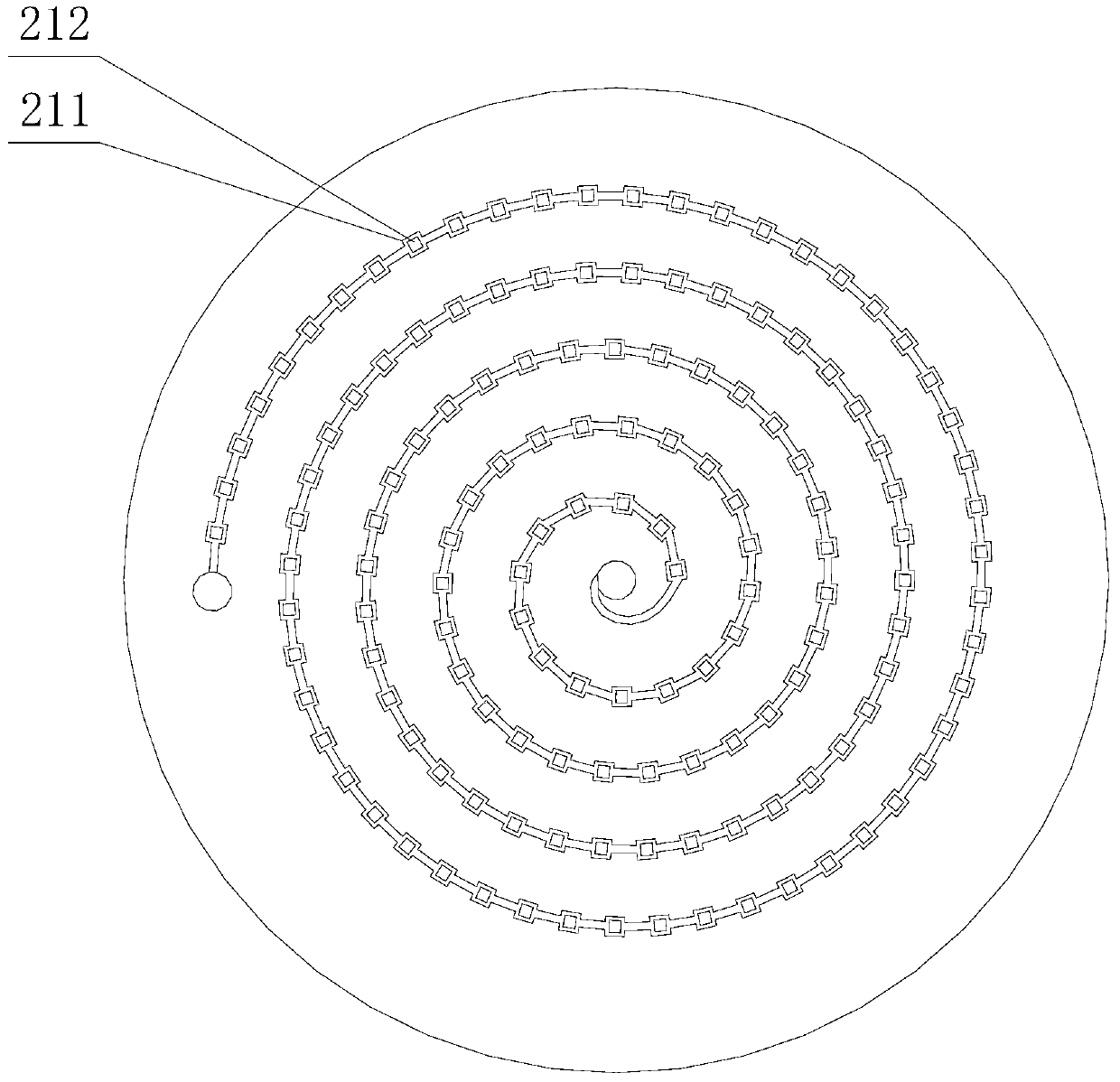

[0057] Preferably, any position on the reaction channel is also provided with a spoiler structure 21 for disturbing the fluid flowing through the position; the spoiler structure 21 has a spoiler effect on the fluid passing through, so The fluids are mixed, causing the fluids to react.

[0058] Further preferably, the flow turbulence structure 21 includes a blocking structure 212 arranged at any position in the reaction channel to block the flow of the reaction fluid, or the flow turbulence structure 21 is included at any position in the reaction channel An expansion structure 211 formed by expanding the channel;

[0059] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com