Method for manufacturing impeller locking ring forgings for large wind turbines

A manufacturing method and locking ring technology, applied in the field of forging, can solve problems such as ring forging technology is not very mature, achieve the effect of shortening the production cycle and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further illustrated by the following examples: According to the following examples, the present invention can be better understood. However, those skilled in the art can easily understand that the specific material ratios, process conditions and results described in the examples are only used to illustrate the present invention, and should not and will not limit the present invention described in the claims.

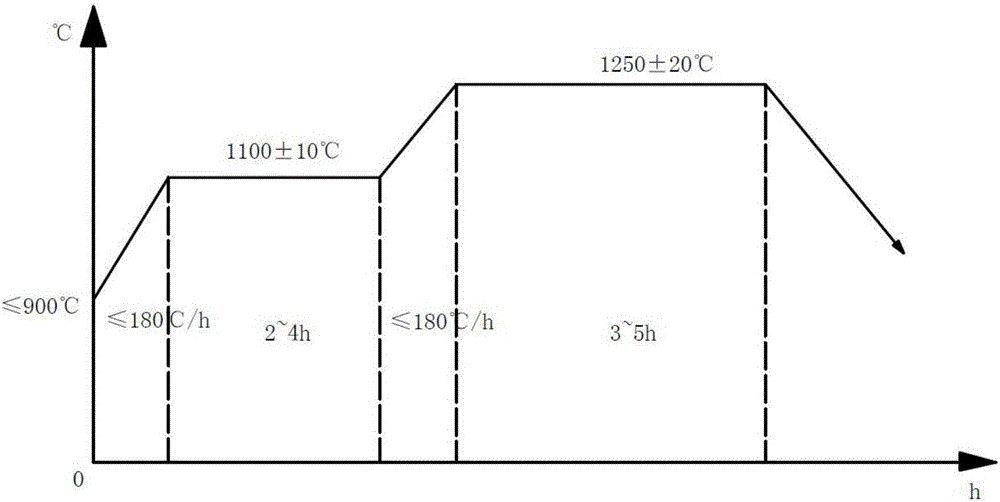

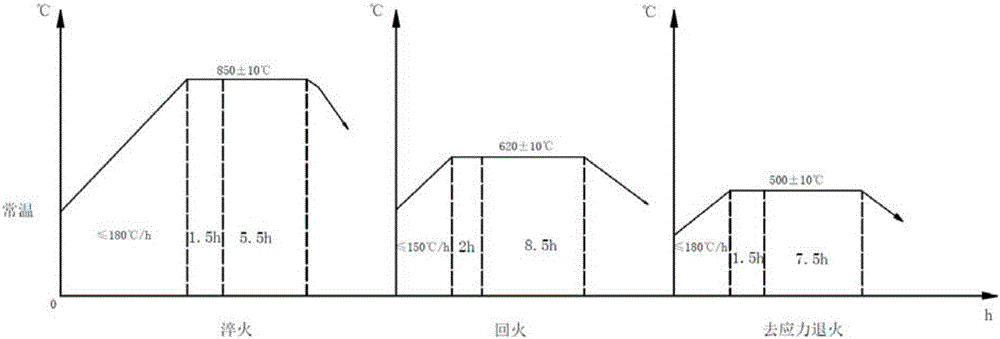

[0035] A method for manufacturing a large-scale wind power impeller locking ring forging, the forging size is Φ2220mm×Φ1840mm×380mm, and the process method includes:

[0036] 1. Cutting material:

[0037] Material grade: 42CrMo billet specification: Φ800 billet, furnace number: E21507061QX, billet weight: 7150kg. Cutting requirements: the cutting surface is flat, without creases, and the cutting surface is perpendicular to the center line of the square ingot.

[0038] The chemical composition of 42CrMo billet includes according to mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com