Numerical control woodworking machine system

A technology for CNC woodworking machine tools and machine tools, applied in the field of machining, can solve problems such as troublesome clamping and inability to guarantee concentricity, and achieve the effects of saving use costs, simple operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

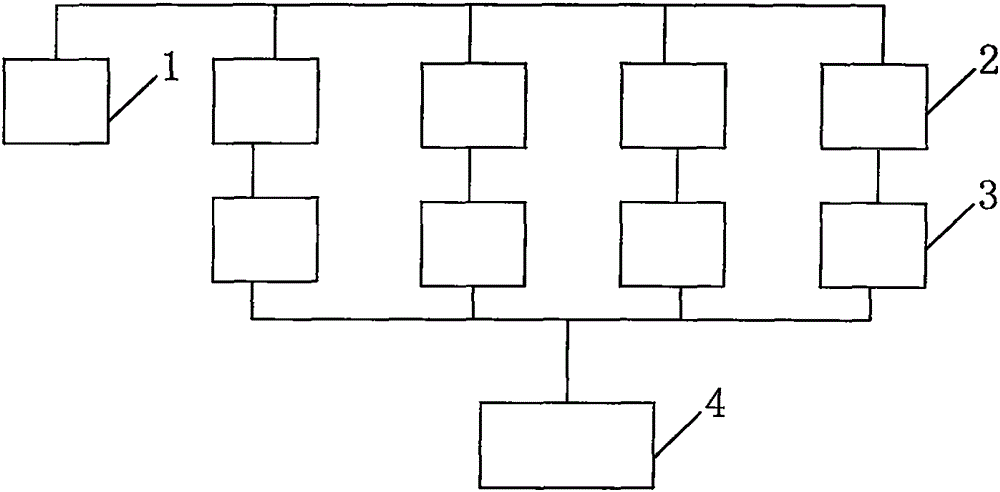

[0018] The CNC woodworking machine tool system provided by the present invention includes an AC servo driver 2, an AC servo motor 3, a numerical control device 1 and a machine tool 4, wherein the AC servo driver 2 receives the position information command of the numerical control device 1 to drive the respective connected motors 3 to run, and Feedback the position information of its control motor 3 to the numerical control device 1; the AC servo motor 3 is connected with the lead screw and / or the main shaft of the machine tool 4; The AC servo driver 2 controls the operation of the AC servo motor 3 to complete the woodworking processing work. The numerical control device 1 is provided with a program input mechanism, and the program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com