Method of preparing glass test samples

A technology for testing samples and glass, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of uneven glass body, affecting the accuracy and reliability of test results, and unable to find stress fringe images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

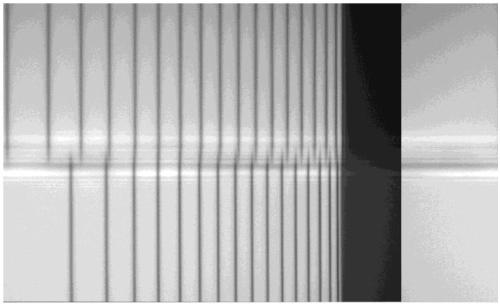

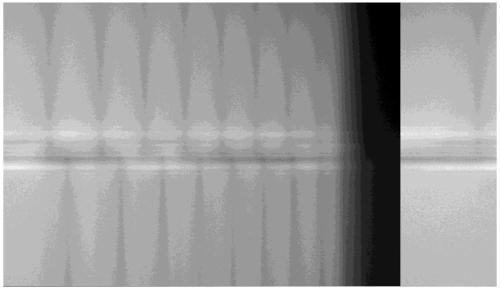

Image

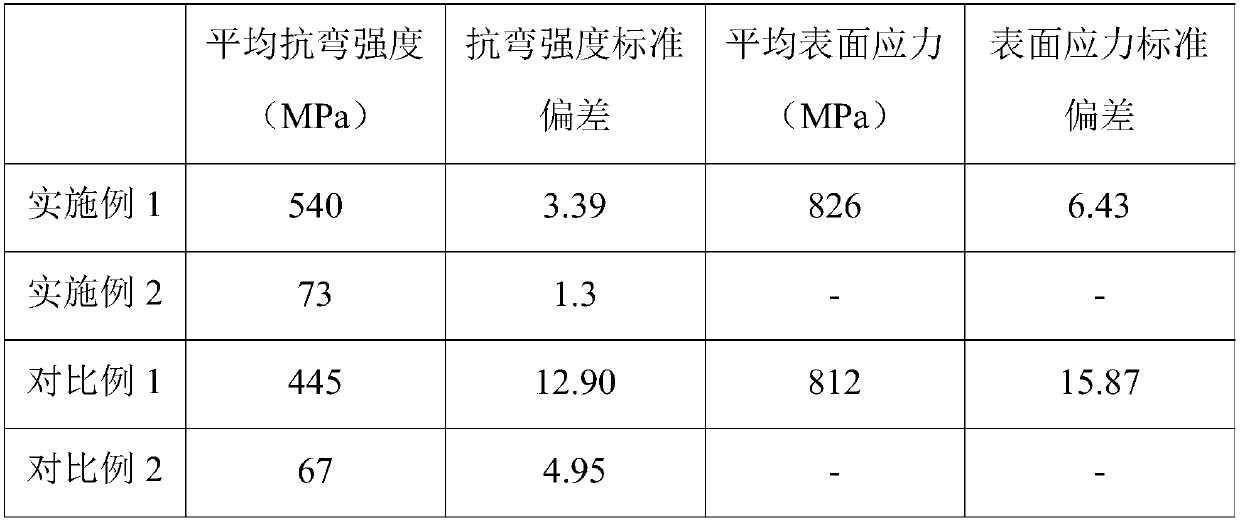

Examples

Embodiment 1

[0031] After weighing according to the cover glass formula, pour the glass material into a plastic ziplock bag, seal the ziplock bag with a certain amount of air, roll up the mouth of the bag to form a sealed space, hold the ziplock bag with both hands, and mix it by shaking. Minutes to get a uniform mixed material. A rectangular corundum tank with a wall thickness of 4mm and a length*width*height of 80mm*65mm*90mm is placed on a refractory tray and placed in a muffle furnace to preheat to 800℃. The material of the corundum tank is white corundum. Then, the mixed materials are slowly added to the preheated corundum tank placed on the refractory tray, and then the tray and the filled corundum tank are placed in the set operating curve high-temperature sample melting furnace for melting treatment and melting treatment The temperature is 1580°C and the time is 7.5h. A platinum stirring rod is used to stir and homogenize the molten glass 2 hours before the completion of the melting...

Embodiment 2

[0033] After weighing according to the TFT-LCD glass formula, pour the glass material into the plastic ziplock bag, seal the ziplock bag with a certain amount of air, roll up the mouth of the bag to form a sealed space, hold the ziplock bag with both hands, and mix it by shaking. A uniform mixed material is obtained in 4 minutes. A rectangular corundum tank with a wall thickness of 6mm and a length*width*height of 100mm*90mm*100mm is placed on a refractory tray and placed in a muffle furnace to be preheated to 700℃. The material of the corundum tank is zirconium corundum. Then, the mixed materials are slowly added to the preheated corundum tank placed on the refractory tray, and then the tray and the filled corundum tank are placed in the set operating curve high-temperature sample melting furnace for melting treatment and melting treatment The temperature is 1600°C, and the time is 7.5h. The platinum stirring rod is used to stir and homogenize the molten glass 3 hours before t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com