Environment-friendly gray plastic material and preparation method thereof

A grey plastic and environmentally friendly technology, applied in the field of interior and exterior decoration construction and ancient building repair, can solve the problems of complex production procedures, high production environment requirements, poor operability and other problems, achieve simple preparation, eliminate worries about harmful substances, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

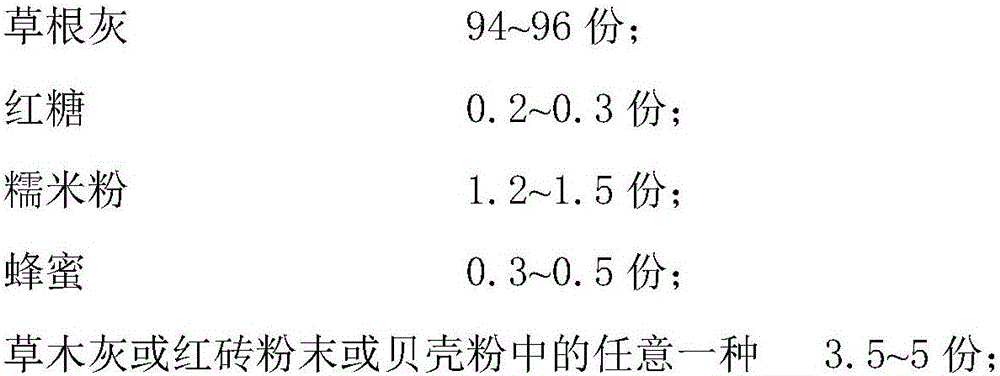

[0025] Environmentally friendly gray plastic materials include:

[0026]

[0027] Wherein, the grass root ash specifically includes according to parts by weight:

[0028] 35 parts dry straw;

[0029] 50 parts of lime paste;

[0030] 30 parts of water.

Embodiment 2

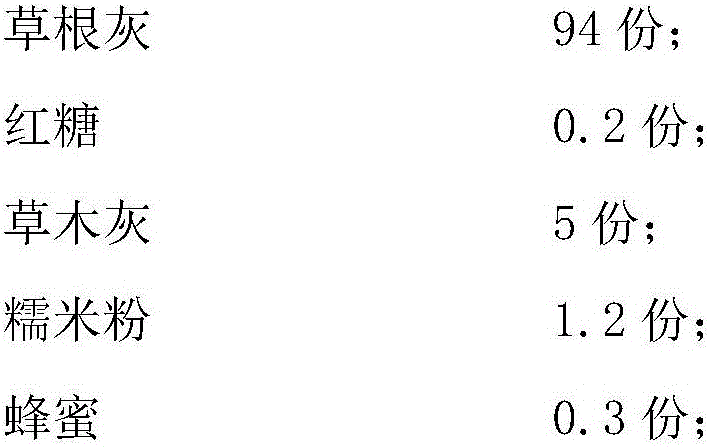

[0032] Environmentally friendly gray plastic materials include:

[0033]

[0034] Wherein, the grass root ash specifically includes according to parts by weight:

[0035] 30 parts dry straw;

[0036] 45 parts of lime paste;

[0037] 25 parts of water.

Embodiment 3

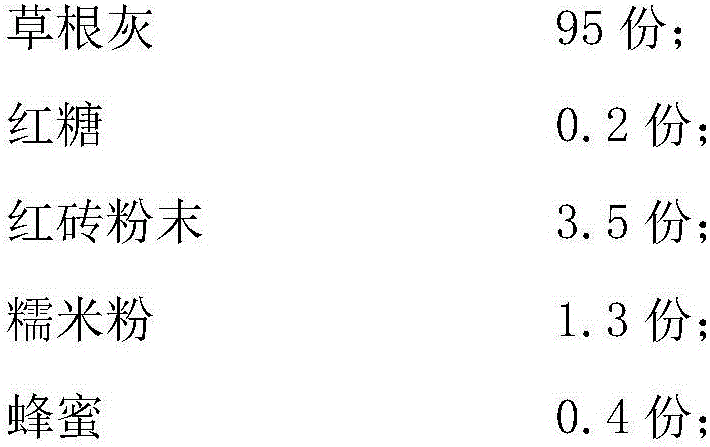

[0039] Environmentally friendly gray plastic materials include:

[0040]

[0041] Wherein, the grass root ash specifically includes according to parts by weight:

[0042] 25 parts dry straw;

[0043] 40 parts of lime paste;

[0044] 20 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com