Special travelling frame for pure electric hydraulic excavator

A hydraulic excavator and walking frame technology, applied in the field of hydraulic pressure, can solve problems such as easy breakage, achieve the effects of not being easy to twitch, simplify the disassembly process, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

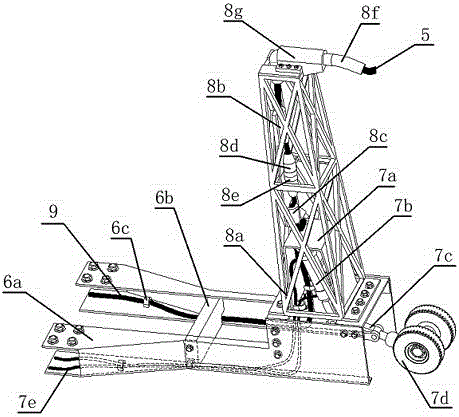

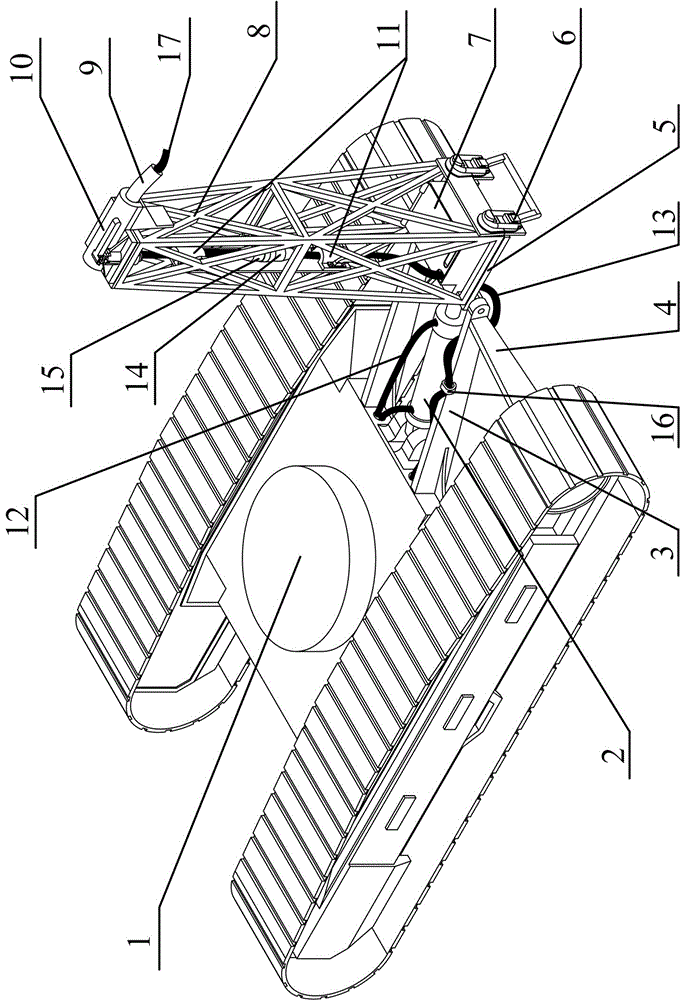

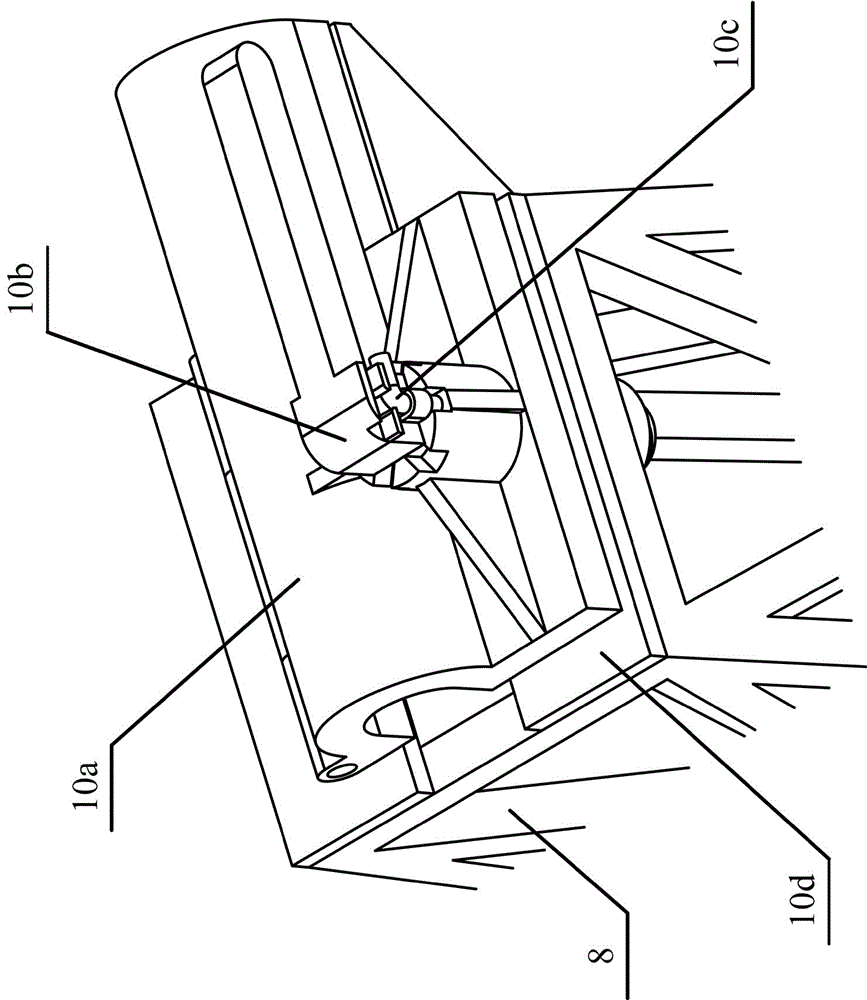

[0009] like figure 1 As shown, the present invention is a special walking frame for a pure electric hydraulic excavator, consisting of a walking frame 1, a hydraulic cylinder 2, a main support beam 3, an auxiliary support beam 4, a branch frame base 5, a branch frame connection device 6, a storage box 7, Branch frame 8, anti-fatigue rubber sleeve 9, cable locking device 10, cable fixing splint 11, hydraulic pipe 12, one end of the main support beam 3 is connected to the end of the walking frame 1, and one end of the auxiliary support beam 4 is connected to the outside of the end cover of the driving device , the main support beam 3 is connected to the end of the auxiliary support beam 4, the hydraulic pipe 12 protrudes from the end of the walking frame 1, and is connected to the hydraulic cylinder 2, the cylinder body of the hydraulic cylinder 2 is hinged to the end of the walking frame 1, and the piston rod is connected to the base of the branch frame 5 The bottom is hinged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com