Prestressed rib connecting and tensioning device and method

A tensioning device and prestressing tendon technology, applied in the erection/assembly of bridges, structural elements, building components, etc., can solve the problems of difficulty in accurate control of tensioning stress, high risk, loss of anchorage compression prestress, etc. To achieve the effect of easy construction and use, convenient and safe operation, and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention includes fractured prestressed tendon connections and prestressed tensioning devices, which will be described separately below.

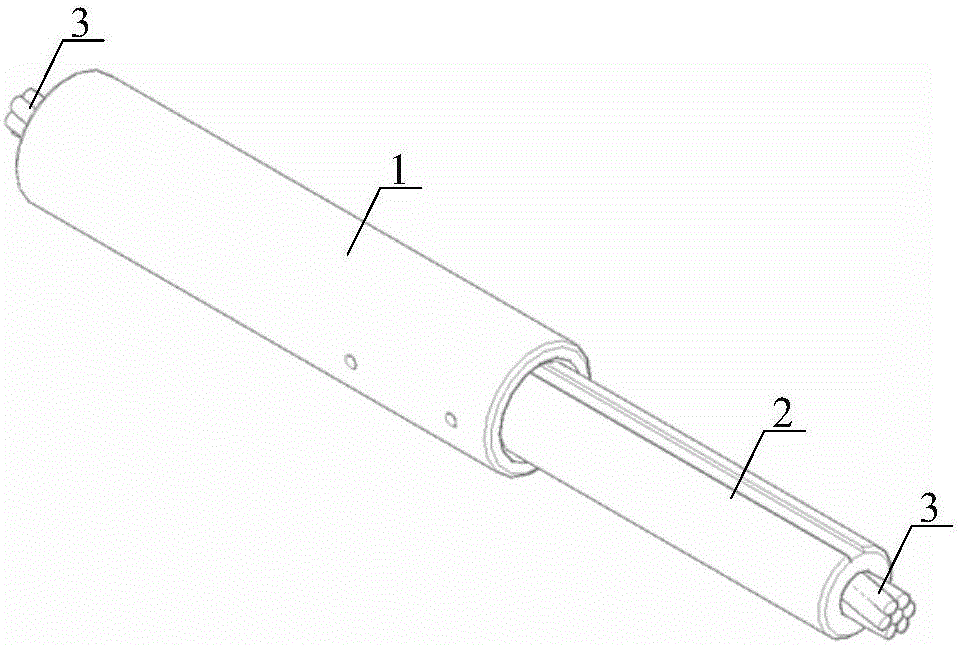

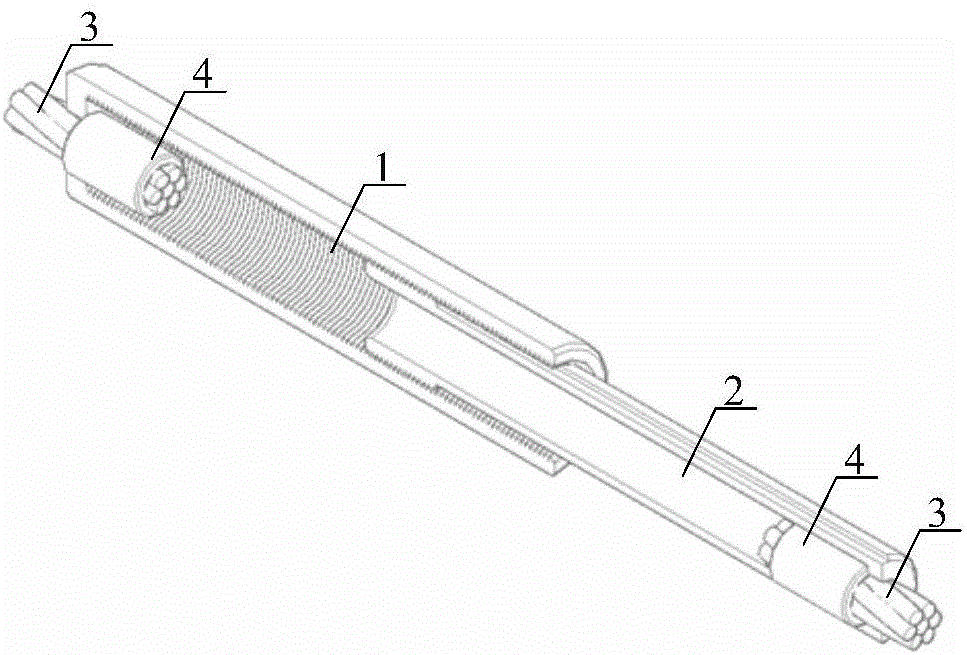

[0028] see figure 1 , figure 2 , The fracture prestressed tendon connecting device of the present invention includes a large sleeve 1 and a small sleeve 2 . The side walls of the two sleeves are centrally opened, and the two ends of the fractured prestressed tendons 3 pass through respectively, and are connected to the sleeves through extrusion anchors 4; the inner wall of the large sleeve 1 and the outer wall of the small sleeve 2 are provided with threads, and the two ends Thereafter, the distance between the large sleeve 1 and the small sleeve 2 is tightened by the prestress tension device to achieve the effect of tension prestress.

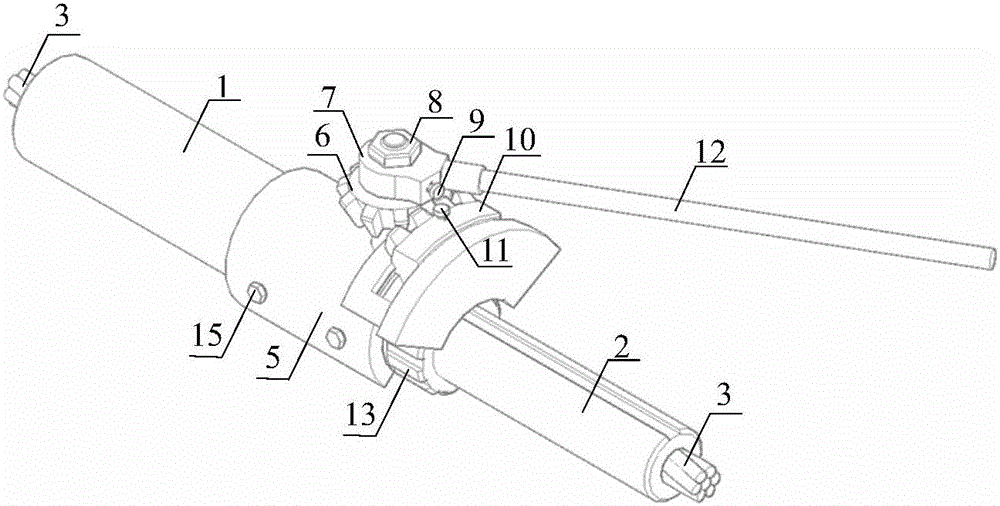

[0029] see image 3 , Figure 4 , the tensioning device of the present invention consists of base 5, bevel gear and ratchet combination 6, ratchet cap 7, nut 8, four-way ratchet 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com