Vehicle-mounted turbocharger monitoring system and method for motor vehicle

A technology of turbocharger and monitoring system, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problem that the engine cannot produce power and fuel economy, the working process of the turbocharger and the deviation of the design point, the turbocharger The supercharger and the engine cannot be well matched, etc., to achieve the effect of excellent engine power performance, high reliability, and credible test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

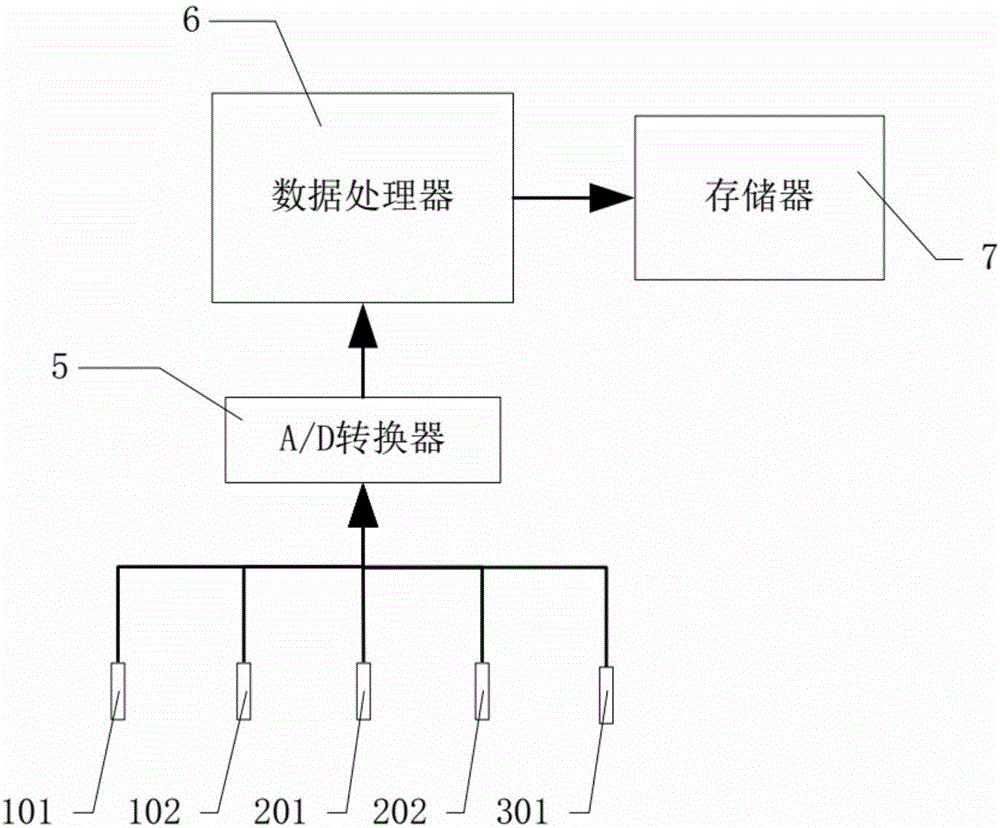

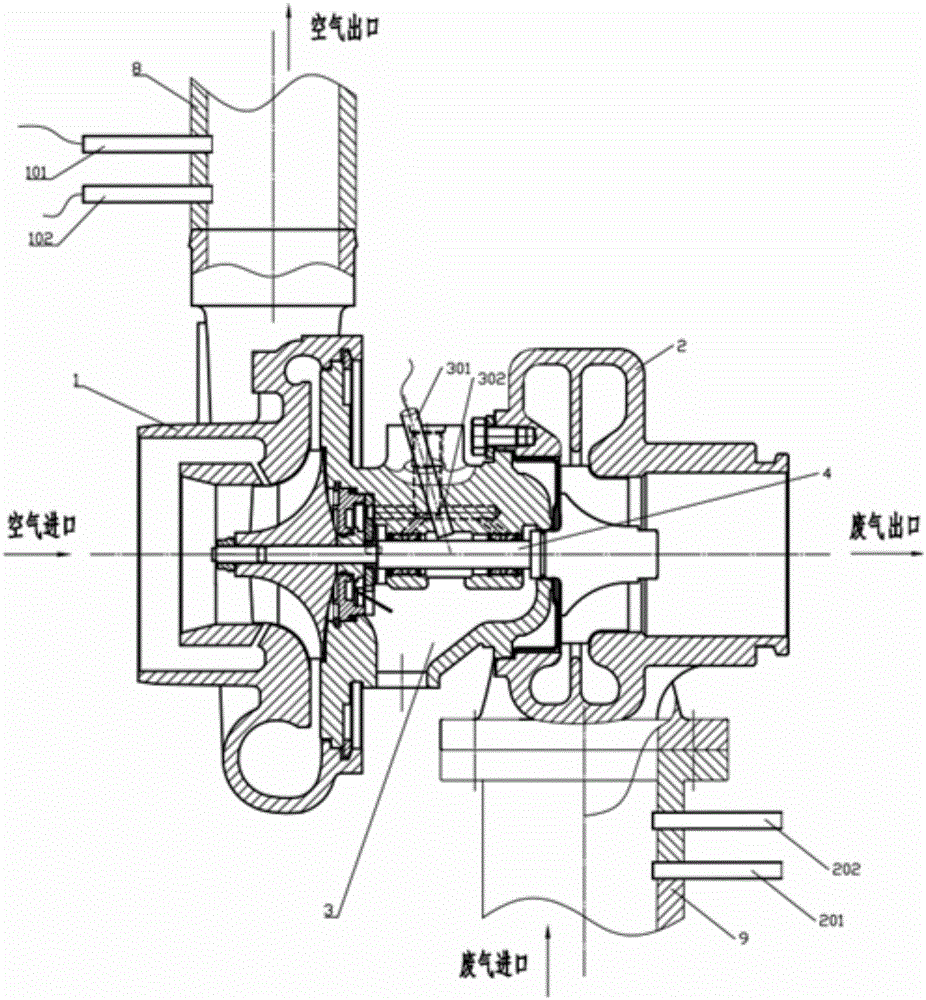

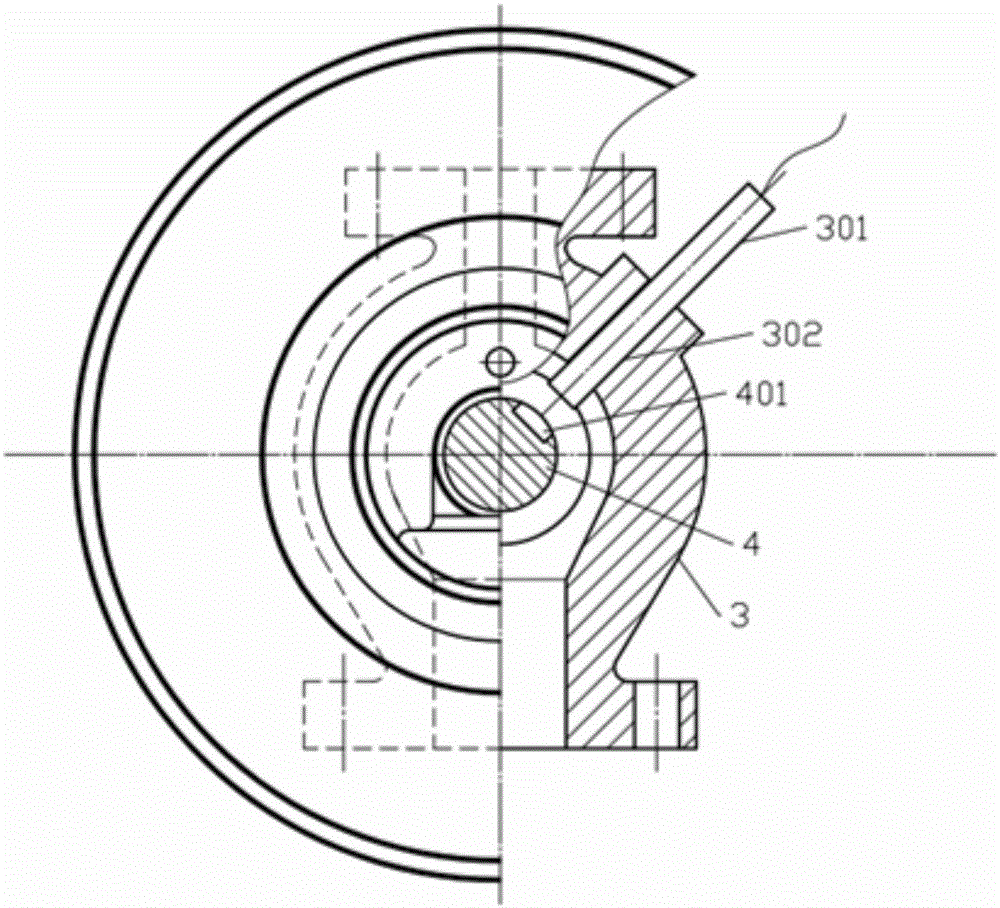

[0024] Such as Figure 1~4 As shown, a vehicle-mounted turbocharger monitoring system includes an A / D converter 5, a data processor 6, a memory 7, a turbocharger rotational speed sensor 301, a compressor exhaust pressure sensor 101, and a compressor exhaust Temperature sensor 102, turbine intake pressure sensor 201 and turbine intake temperature sensor 202, the supercharger speed sensor 301 adopts an electric eddy current speed sensor, and is installed on the turbocharger intermediate body 3, the intermediate body 3 A mounting hole 302 for installing a supercharger speed sensor 301 is provided near the oil inlet hole, and the other end of the mounting hole 302 is connected to the oil chamber between the two floating ring bearings inside the intermediate body 3; it is located between the two floating ring bearings The turbine rotor shaft 4 is processed with a speed measuring groove 401 for speed measurement, and the speed measuring groove 401 is arranged axially along the turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com