Wind driven generator transmission mechanism adopting chain wheels for speed increasing

A technology for wind turbines and transmission mechanisms, which is applied to wind turbines, engines, machines/engines, etc., can solve problems such as inability to adapt to high-speed transmission, decreased meshing performance with sprockets, and changes in chain pitch, reducing complexity. And, the meshing state is good, and the maintenance is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

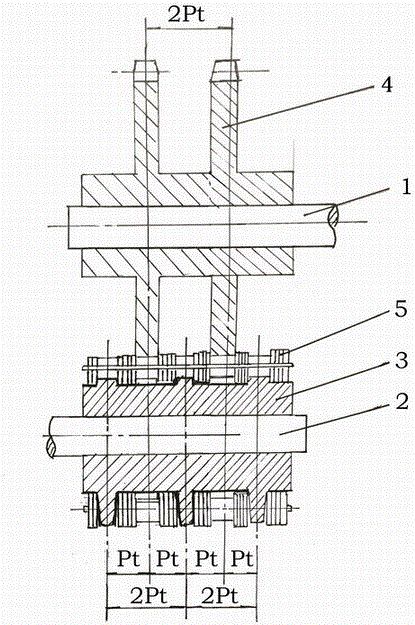

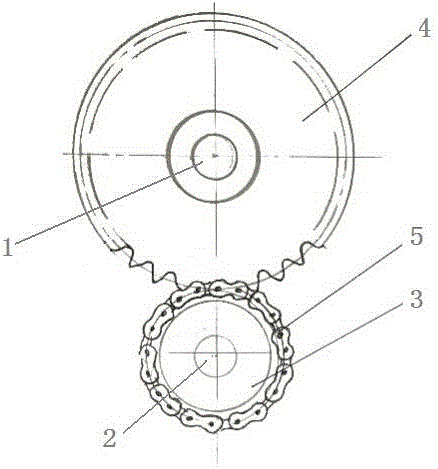

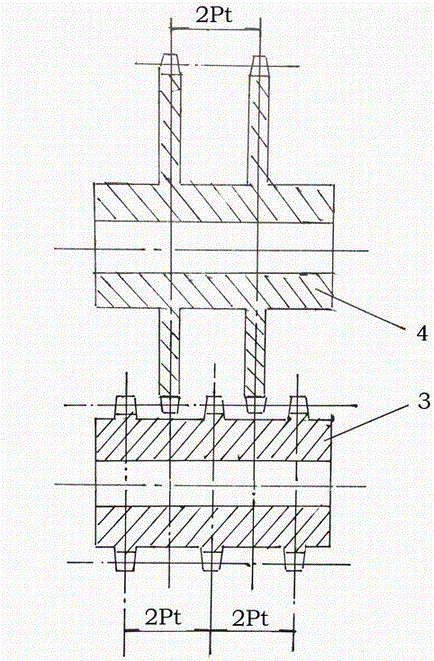

[0021] Such as Figure 1~Figure 3 As shown, 1. high-speed shaft, 2. low-speed shaft, 3. multi-row small sprocket, 4. multi-row large sprocket, 5. multi-row sleeve roller chain.

[0022] A wind power generator transmission mechanism adopting sprocket speed increase, such as figure 1 , figure 2 As shown, it belongs to the field of wind power generators, especially related to the speed-up transmission between the impeller of the wind power generator and the alternator. Output, the low-speed shaft 2 is connected to the impeller and used as power input.

[0023] The high-speed shaft 1 is provided with multiple rows of small sprockets 3 for transmission connection, and the low-speed shaft 2 is provided with multiple rows of large sprockets 4 for transmission connection. The transmission connection has various structural forms, and key connection is usual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com