Probe adjusting device for ultrasonic measurement of wall thickness of titanium alloy tube

An ultrasonic measurement and adjustment device technology, applied in the measurement device, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of difficult to ensure the bottom surface of the probe, unable to be in the best position for detection, etc., to ensure the accuracy of measurement, Wide range of applications and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

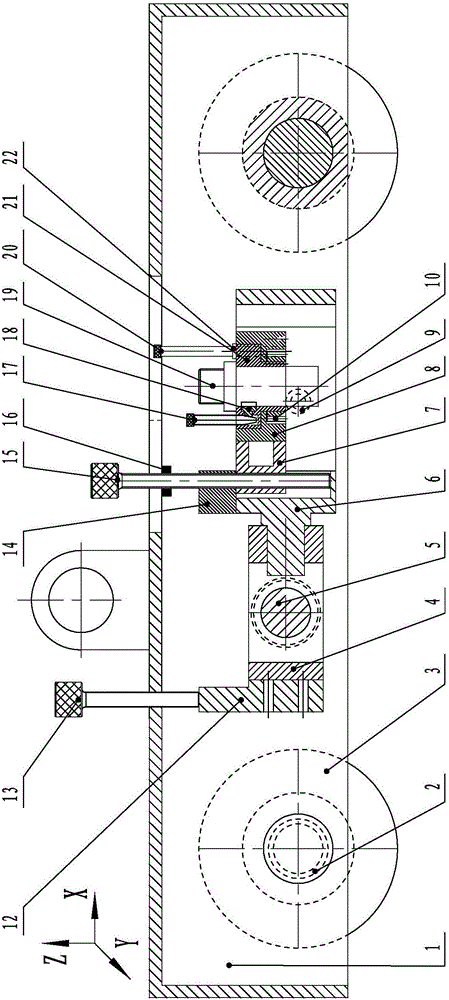

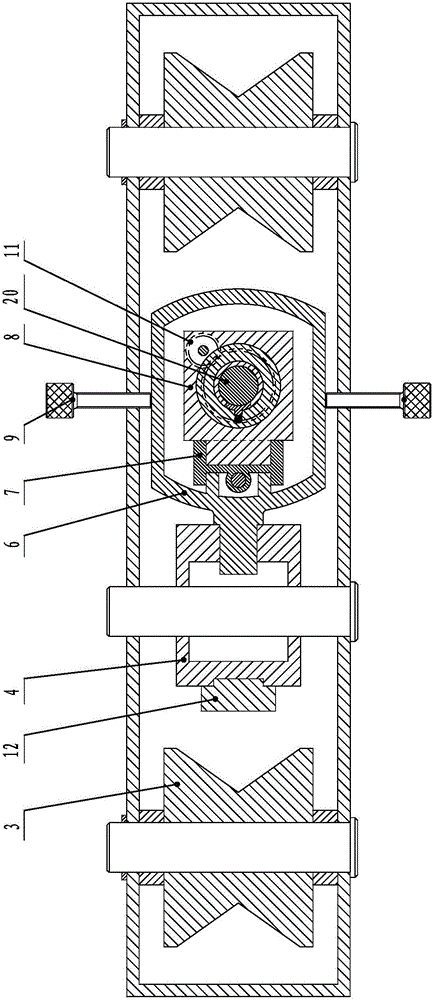

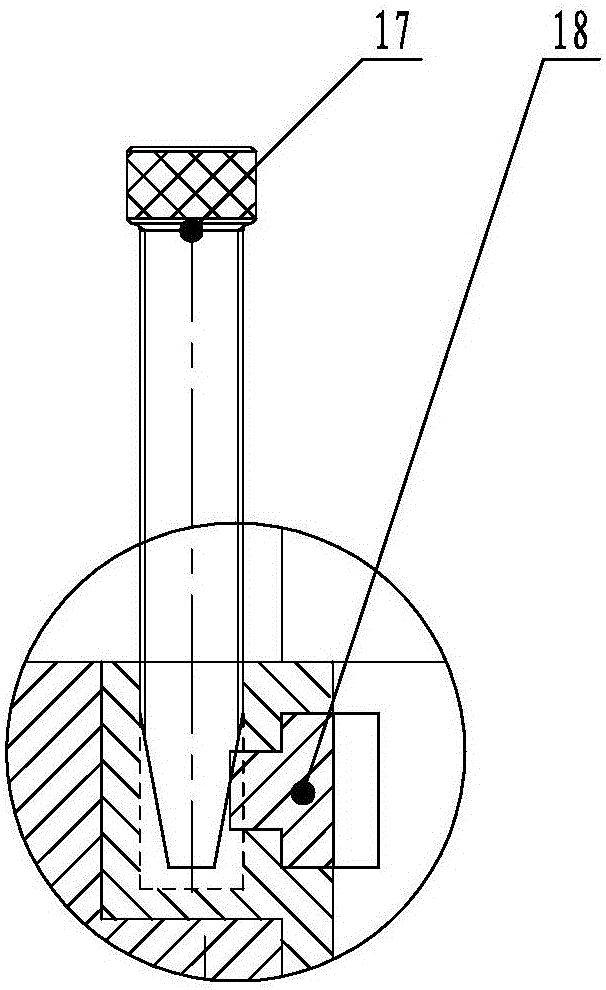

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0025] Such as figure 1 , figure 2 As shown, the detection device housing 1 is preferably a box-like structure with an open lower end, and guide wheels 3 are arranged at the front and rear ends of the detection device housing 1 inner cavity, and the guide wheels 3 are preferably rollers of nylon material. The lower edge is lower than the bottom surface of the detection device housing 1 . The guide wheel 3 is sleeved on the wheel shaft 2, and the two ends of the wheel shaft 2 are connected with the detection device housing 1 and fixed by cotter pins. The guide wheel 3 can rotate relative to the wheel shaft 2.

[0026] Such as figure 1 , figure 2 As shown, a first connecting piece 4 is provided inside the detection device housing 1 , and the first connecting piece 4 is located between two guide wheels 3 . The first connecting part 4 is preferably a squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com