Scraper conveyor chain fluttering fault diagnosis method

A scraper conveyor and fault diagnosis technology, which is applied in the field of coal mining, can solve the problem of no good detection method for floating chain faults, and achieve the effects of reasonable design, simple implementation, and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, content of the present invention is described in detail:

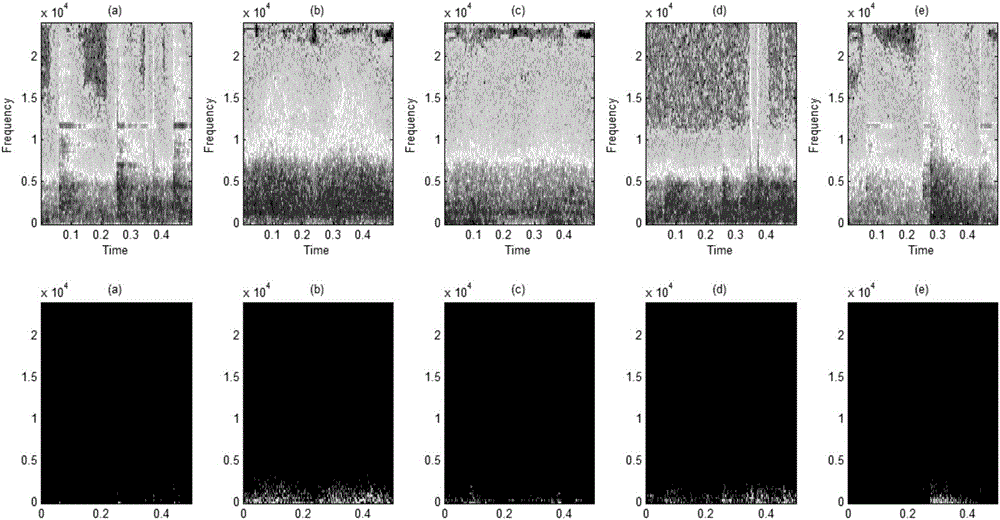

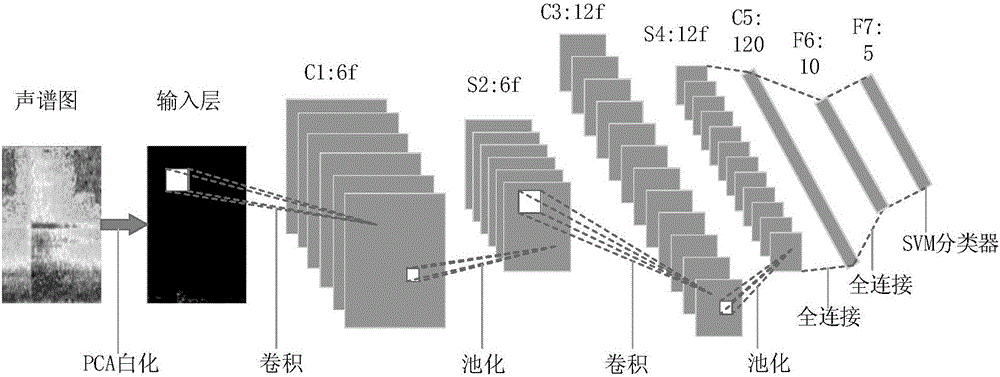

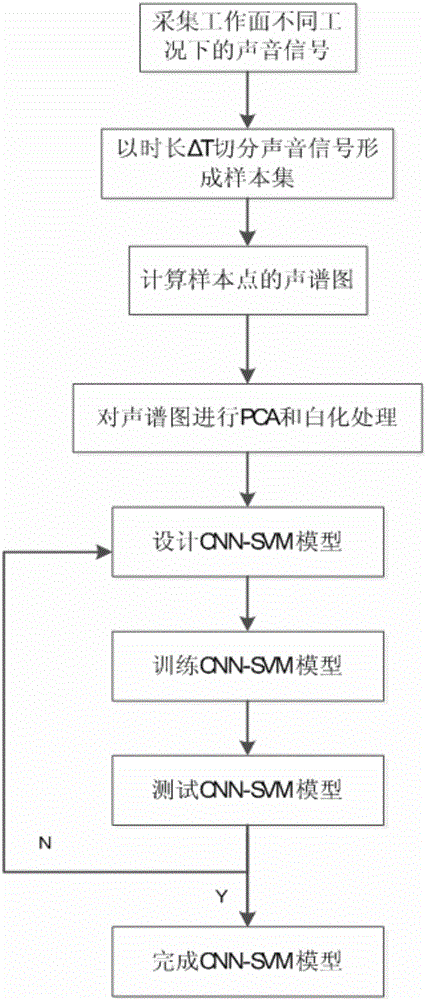

[0018] 1. The sources of equipment sound during the production process of fully mechanized mining face are scraper conveyor and shearer. Among them, the shearer is mainly the vibration of the fuselage and the sound of the drum cutting the coal wall, and the scraper conveyor is mainly It is the sound of the scraper and the chain rubbing against the trough. The sound of these two devices is relatively stable under normal conditions. When a floating chain failure occurs somewhere on the scraper conveyor, there will be a sound of the scraper and the chain hitting the trough. Metal impact sound, when the shearer drum cuts to the shovel plate of the scraper conveyor, the metal impact sound of the shearer blade colliding with the shovel plate of the scraper conveyor will also be issued. When it is rocky or overloaded, it will also emit different abnormal sounds; the spect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com