Rock specimens for rock shear strength testing and test methods

A rock sample, shear strength technology, applied in the field of shear strength test, rock sample, can solve the problems of expensive equipment, limited popularization, stress concentration, etc., to weaken the end effect, improve the test accuracy, and reduce the contact area Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

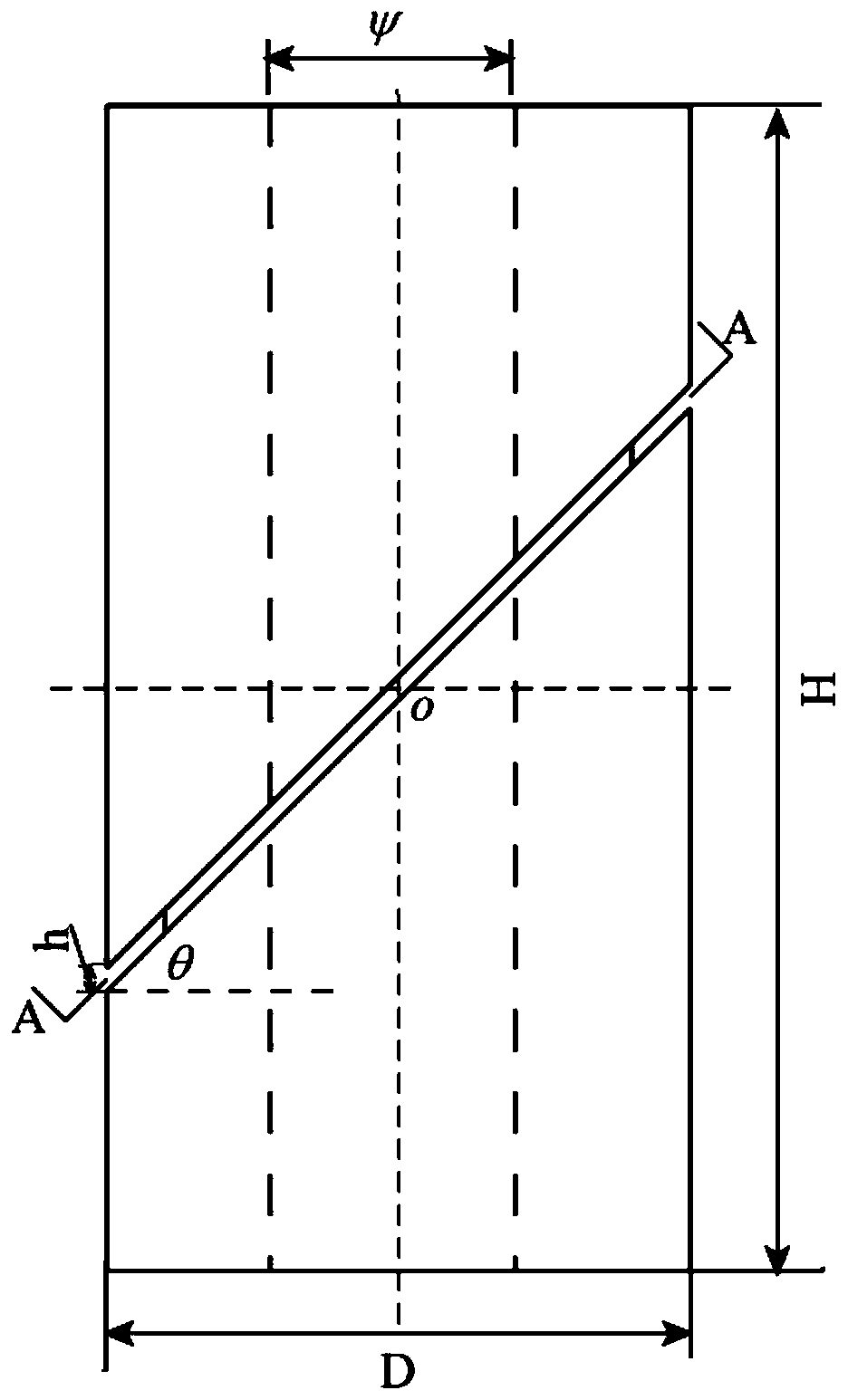

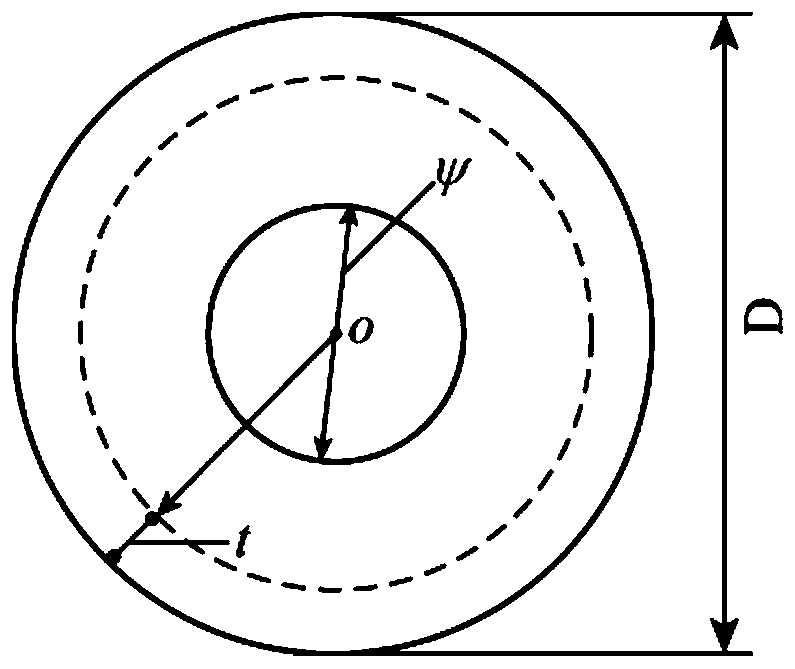

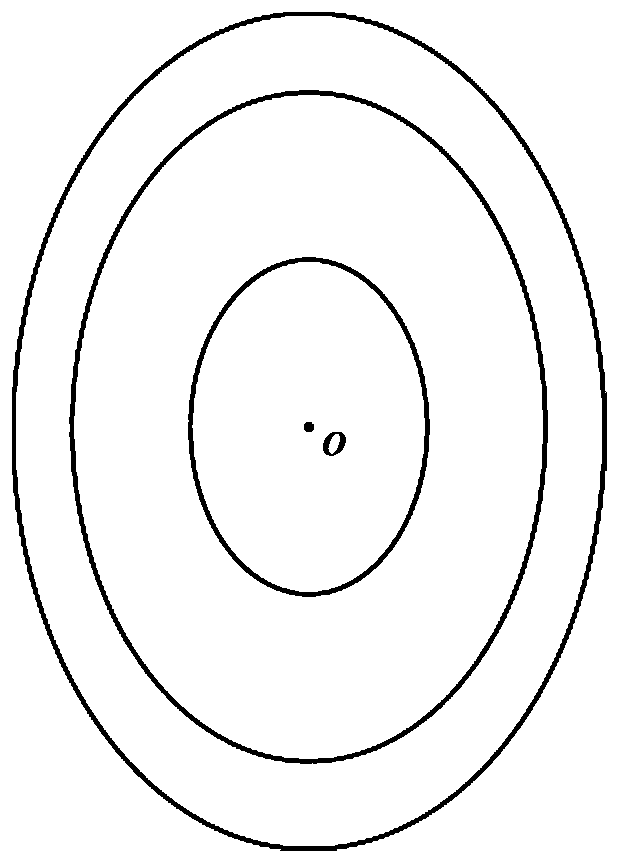

[0046] The rock specimen structure that is used for rock shear strength test in the present embodiment is as Figure 1-3 As shown, the body of the rock sample is a hollow cylinder with a coaxial cylindrical hole processed in the center, and an oblique groove with a structure such as a circle around the outer cylindrical surface is processed on the outer cylindrical surface of the hollow cylinder. The section perpendicular to the central axis of the hollow cylinder forms an inclination angle θ, and the center point of the section passing through the beveled groove coincides with the midpoint O of the central axis of the hollow cylinder. The chamfered groove is a chamfered groove with a rectangular cross section.

[0047] The cylinder height H is 100mm, the outer diameter D is 50mm, the inner diameter ψ is 20mm, the height of the annular beveled groove is 2mm, the depth t is 5mm, and the inclination angle θ is: 30°, 40°, 45°, 50°, 55° , 60°, 65°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com