Device for coal-derived bio-methane and method thereof

A biomethane and coal-based technology, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as far apart test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is further illustrated by the following examples, but not limited to the following examples.

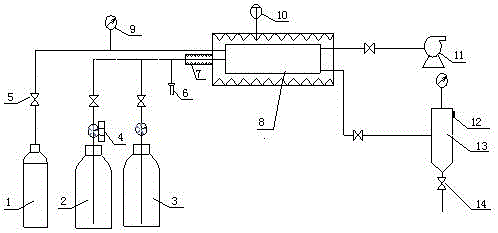

[0044] Such as figure 1 As shown, a coal-to-biomethane device includes a reactor 8, an anaerobic device, a feeding device, and a separation device; the anaerobic device includes a nitrogen bottle 1 and a vacuum pump 11; the feeding device includes a nutrient solution bottle 2. A peristaltic pump 4 and a check valve 5 are installed above the outlets of the bacterial liquid bottle 3, the nutrient liquid bottle 2, and the bacterial liquid bottle 3, and a flow meter is installed on the connection pipe between the nutrient liquid bottle 2, the bacterial liquid bottle 3 and the reaction kettle 8 6; the reaction kettle 8 is connected to a temperature controller 7; a temperature sensor 10 is provided above the reaction kettle 8; the separation device includes a separation kettle 13, and a pressure gauge and a gas collection port 12 are arranged above the separati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com