Volume holographic element and manufacturing method thereof and manufacturing system thereof

A production method and volume holographic technology, applied in the field of volume holographic components, can solve the problems of low yield rate, low yield rate, and unable to enlarge the format, and achieve the effect of high uniformity, large format, and short focal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

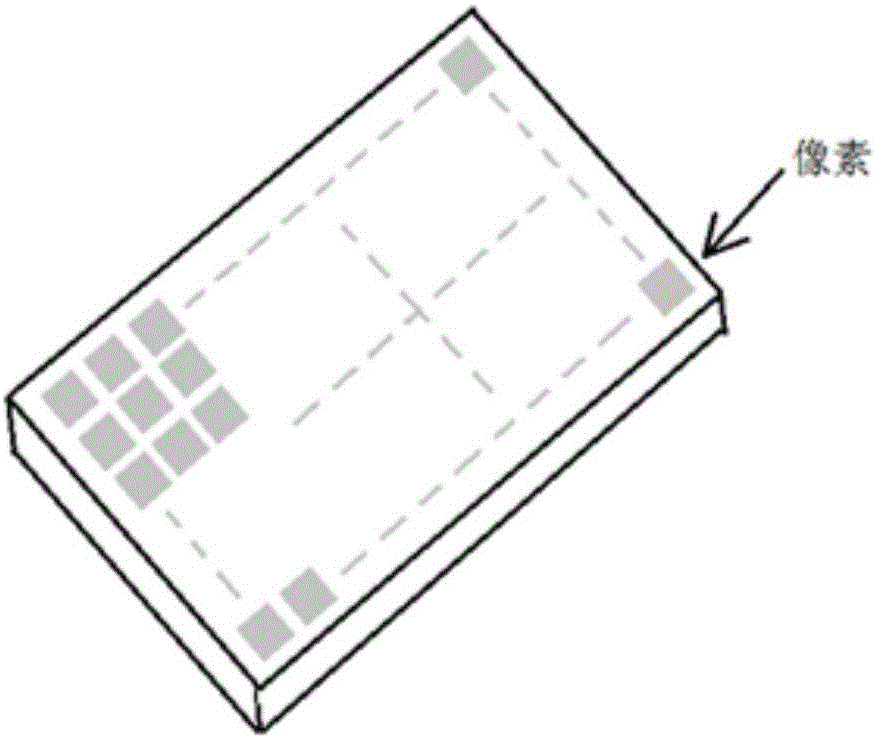

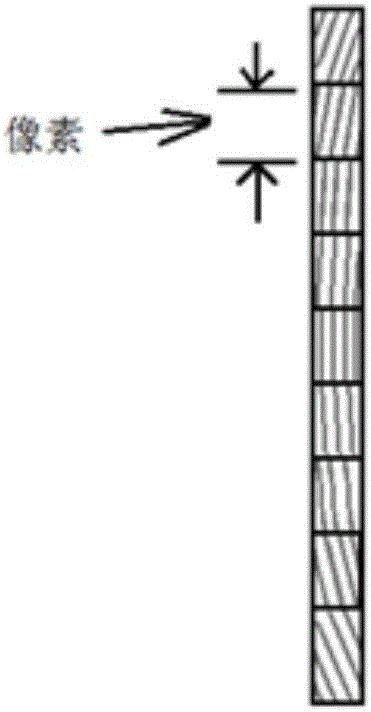

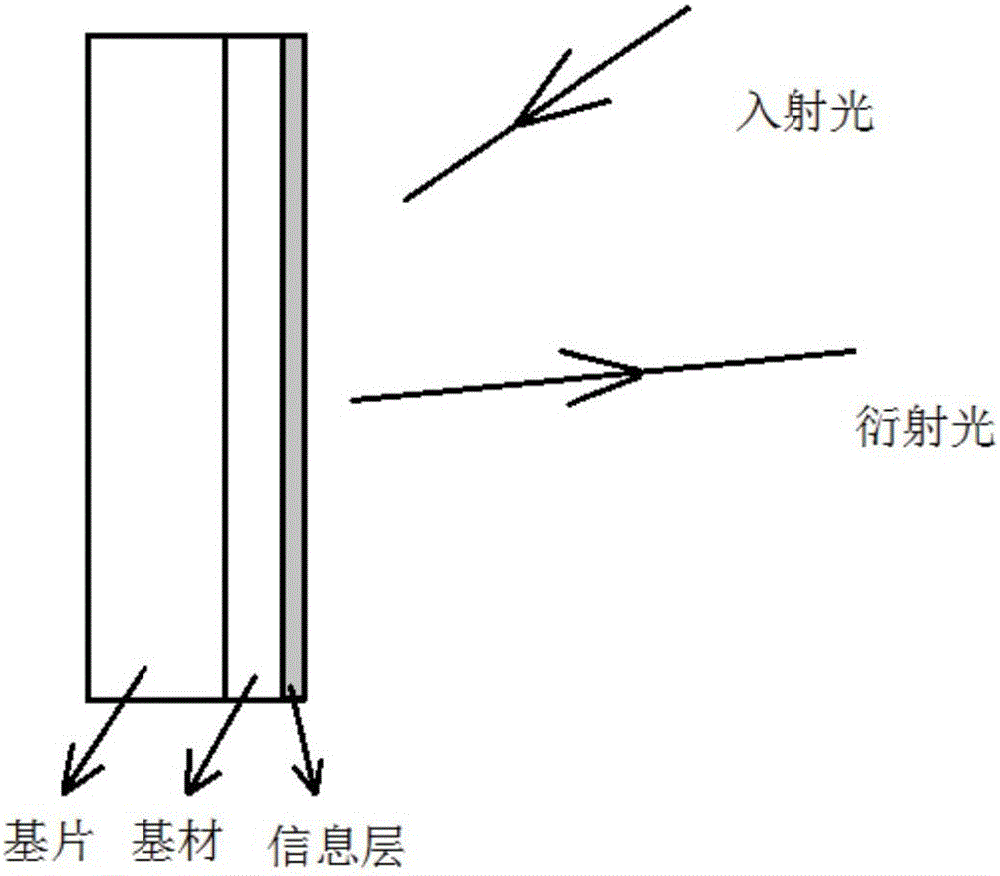

[0074] This embodiment mainly describes a pixelated reflector holographic element, which forms the reflection imaging and forward light transmission functions with the above-mentioned functions. The pixelated reflector holographic element is composed of a substrate and a volume holographic information layer on the substrate. A reflective holographic pixel array inside the information layer. The pixel unit contains a series of interference fringe surfaces, which are parallel or parallel to the surface of the substrate. There are included angles. These array-distributed pixel units with different parameters can not only realize the functions of traditional volume holographic elements, but also realize the control of optical parameters such as complex focal length and multi-focus. The angle change and distribution depend on the reflector holograph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com