Numerical control machine tool CNC machining system

A processing system, CNC machine tool technology, applied in general control system, control/adjustment system, program control, etc., can solve the problem of inability to optimize control of machine tool spindle plus process parameters, tool wear, damage, and inability to monitor and deal with machine tool vibration in real time And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

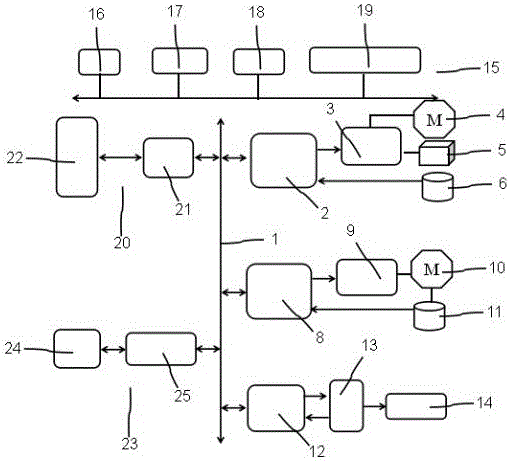

[0019] This embodiment: as figure 1 As shown, a CNC machining system of a numerically controlled machine tool 14 includes a CNC machining system bus 1, the CNC machining system bus 1 communicates with the feed axis position control system interface 2, and the output of the feed axis position control system interface 2 is connected to the speed Servo system 3, the output of the speed servo system 3 is connected to the servo motor 4 and the manufacturing machine 5, the servo motor 4 and the manufacturing machine 5 are respectively output to the first photoelectric encoder 6, and the first photoelectric encoder 6 feedbacks the output In feed axis position control system interface 2;

[0020] The CNC machining system bus 1 communicates with the spindle control system interface 8, the output of the spindle control system interface 8 is connected to the spindle drive device 9, the spindle drive device 9 is connected to the spindle motor 10, and the spindle motor 10 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com