Information acquisition device of machine tool

A technology for information acquisition and information extraction, applied in computer control, instruments, simulators, etc., can solve the problems of machine tool damage, the inability of the tool to process the workpiece into the desired size and shape, etc., to achieve the effect of improving analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

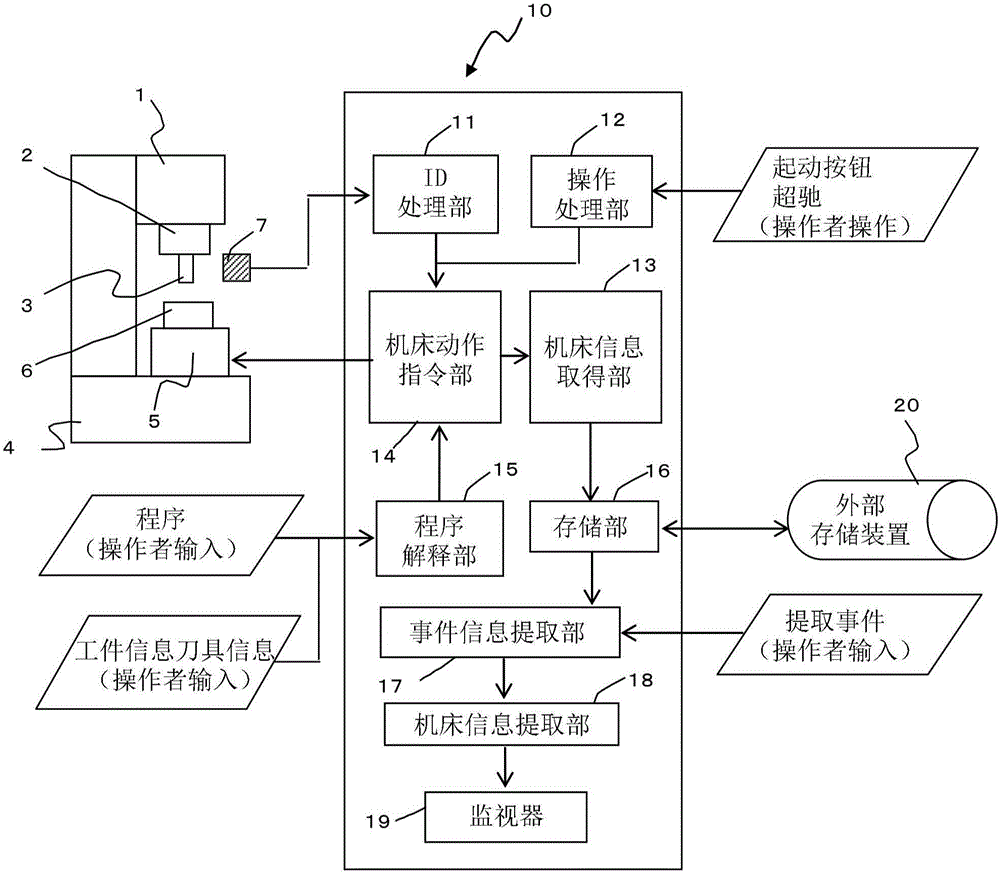

[0042] Embodiments of the present invention will be described below with reference to the drawings.

[0043] figure 2 It is a unit configuration diagram showing an example of a machine tool. A spindle housing 1 of a machine tool is provided with a spindle 2 as a rotating shaft rotatable by a spindle motor, and a tool 3 such as a drill and an end mill is attached to an end of the spindle 2 . A workbench 5 is provided on the bed base 4, and the workpiece 6 is fixed on the workbench 5. The tool 3 and the workbench 5 are relatively moved in the direction of the X-axis, Y-axis, and Z-axis perpendicular to each other through the feed axis mechanism, thereby The machining of the workpiece 6 is performed.

[0044] 10 denotes an NC device that controls the machine tool, and the NC device 10 operates the machine tool according to a program to process the workpiece 6, and also functions as an information acquisition device of the present invention.

[0045] In the NC device 10, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com