Laneway side support design method based on weak plane shear and support theories

A technology of roadway support and design method, applied in design optimization/simulation, calculation, mining equipment, etc. Material waste and other issues, to achieve the effect of ensuring scientificity and applicability, reducing support costs, reducing support materials and support costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

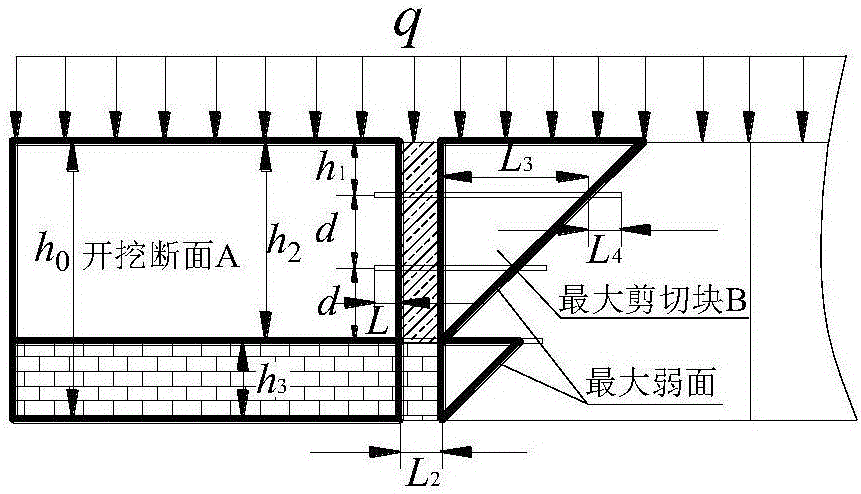

[0035] Embodiment 1. Taking the 31104E middle roadway of a certain mine as an example, the 31104E middle roadway is a semi-coal rock roadway, the coal thickness is 1.6m, the barren height is 2.5m, and the bottom is 0.9m. The specific implementation steps are as follows:

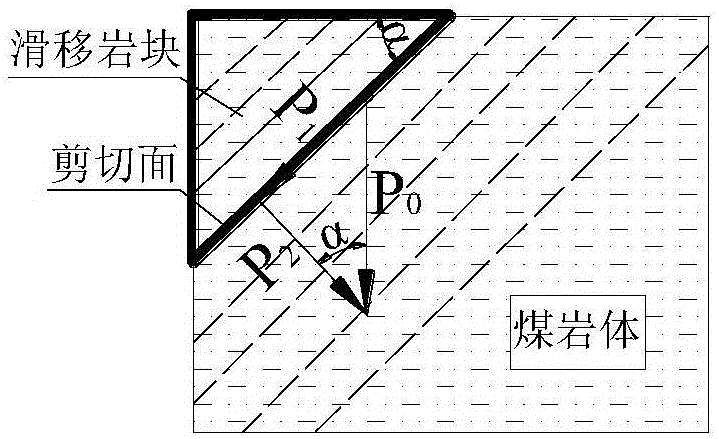

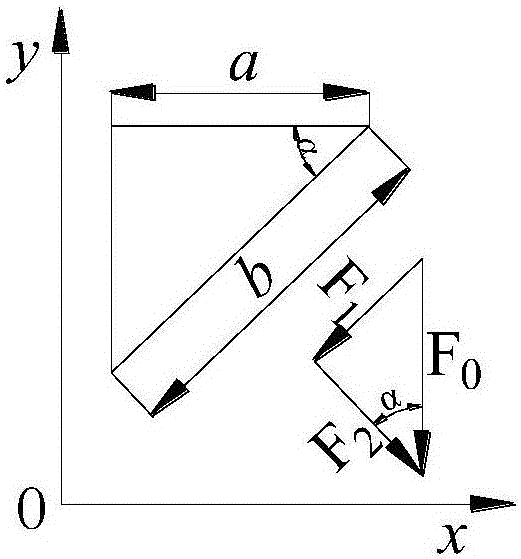

[0036] (1) Establish a force balance mechanical model for the rock mass around the semi-coal-rock roadway to slide and fail along a weak surface under the action of external force, as shown in Figure 1. Assuming that the weak surface shears along the dotted line in the figure, the weak surface is a shear surface, and the angle between the weak surface and the horizontal direction is α, m is the width of the rock block, and the downward normal force exerted on the roadway by the uniform load is f 0 , F 0 The decomposed force along the shear plane and its perpendicular direction is F 1 , F 2 , the compressive strength is P 0 , compressive strength P 0 The decomposed shear strength and its strength in the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com