Method and system for determining asphalt concoction scheme based on viscosity model

A bitumen and viscosity technology, which is applied in the field of bitumen production in the petroleum refining industry, can solve the problems of low accuracy, long detection time, and high cost, and achieve the effects of cost reduction, shortened detection cycle, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

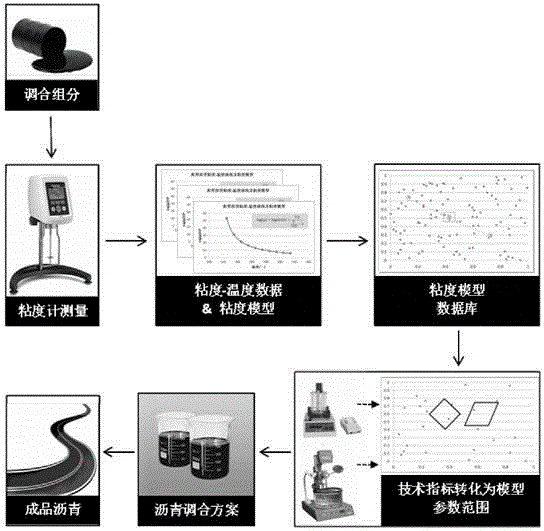

Method used

Image

Examples

Embodiment 1

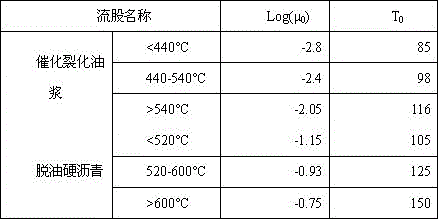

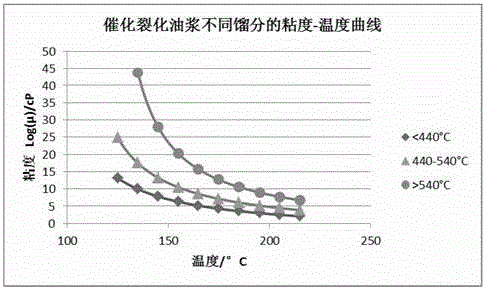

[0099] Embodiment 1: Asphalt is produced by blending catalytic cracking oil slurry and deoiled hard asphalt.

[0100] Catalytic cracking oil slurry is the oil slurry left in the catalytic cracking process in the oil refining process. It is a low value-added product. At present, domestic catalytic cracking oil slurry is generally shipped as cheap heavy fuel oil. The viscosity of FCC oil slurry is low, which cannot reach the viscosity range required by bitumen. Deoiled hard asphalt refers to the residue left after the vacuum residue has been removed by solvents to remove most of the saturated hydrocarbons and lighter aromatic hydrocarbons. Hard and brittle at room temperature, it is difficult to be used as a blending component in asphalt production.

[0101] In this example, the viscosity model of catalytic cracking oil slurry and deoiled hard asphalt is established, and qualified asphalt can be produced by blending the two raw materials in an appropriate ratio. The specific o...

Embodiment 2

[0113] Example 2: Production of asphalt using vacuum residues of two unconventional asphalt crude oils.

[0114] Among the more than 1,500 kinds of crude oil produced in various crude oil producing areas in the world, only 260 kinds of crude oil can be directly produced asphalt. In this example, a viscosity model is established for the vacuum residues of two unconventional asphalt production crude oils: Sudan crude oil and Philippine crude oil, and a scheme for blending these two vacuum residues to produce asphalt is found. Sudan crude oil is dense, and the viscosity of its vacuum residue exceeds the quality specification for bitumen production. The Philippine crude oil is less dense, and the viscosity of its vacuum residue is less than the quality specification for bitumen production. Both of these crudes are therefore generally not bitumen producing crudes. In this example, the asphalt was produced by blending the vacuum residue of these two crude oils through the asphalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com