Autotransformer and test connecting method thereof

An autotransformer and test connection technology, applied in the field of transformer manufacturing, can solve the problems of increasing the operation and maintenance cost of power grid equipment, complicated design and manufacturing of transformers and power stations, and increasing the manufacturing cost of transformers, so as to reduce maintenance costs and installation. The effect of occupying space and reducing the incidence of operating failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

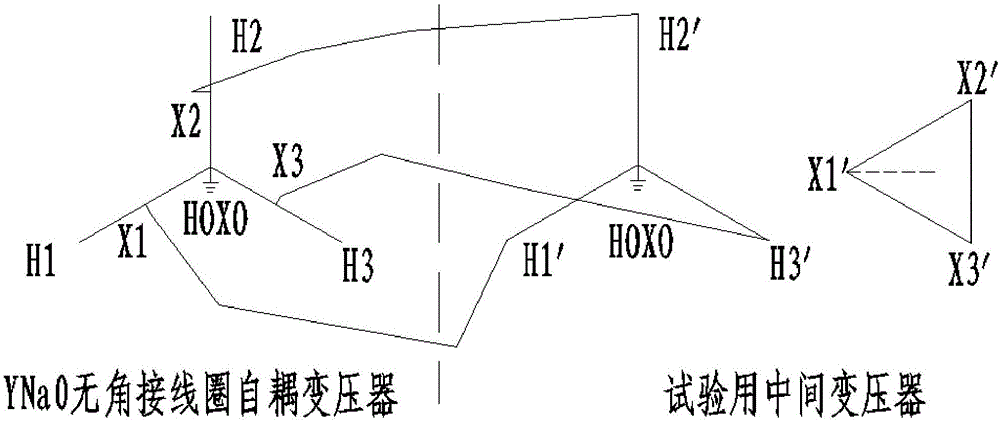

[0021] The autotransformer of the present invention has a three-phase five-column iron core structure, only includes high-voltage coils and low-voltage coils, and the connection group is YNa0. Pressed Coils - Coils in series.

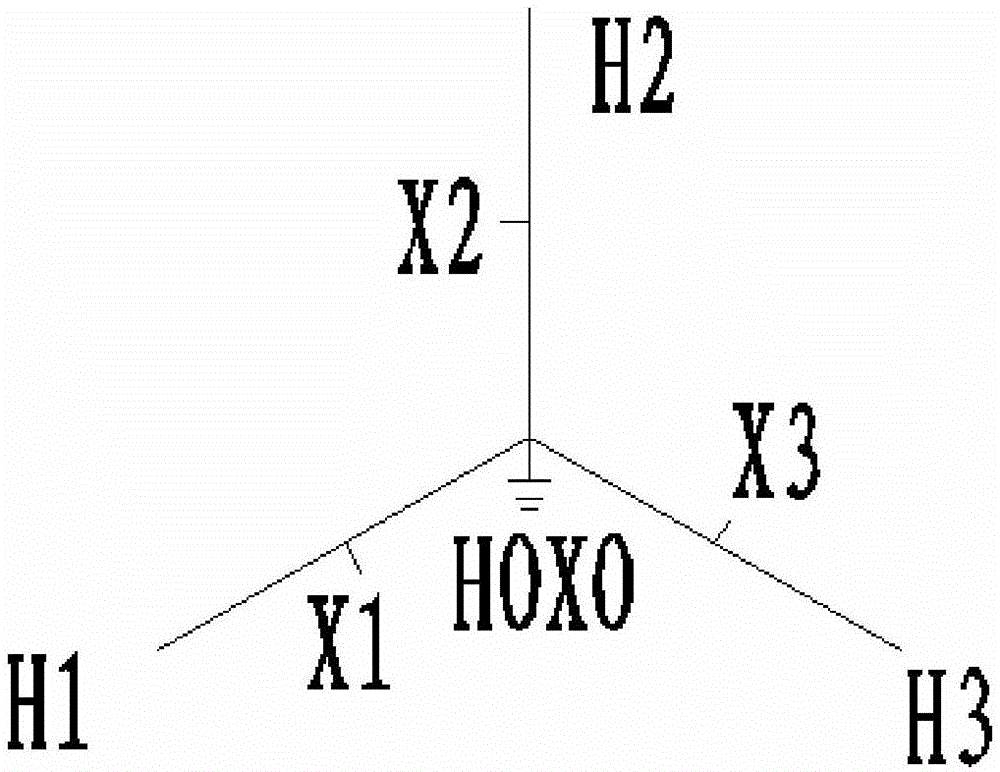

[0022] Such as figure 1 As shown, the connection group of the transformer of the present invention is only YNa0, which is an autotransformer without delta-connected coils.

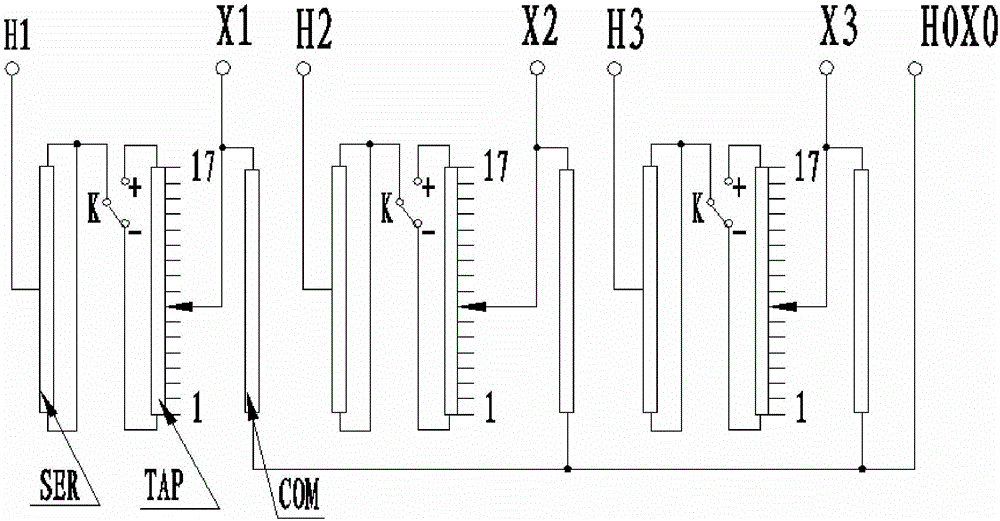

[0023] Such as figure 2 As shown, the autotransformer of the present invention is a high-voltage on-load voltage regulation. The series coil SER of the autotransformer adopts a middle outlet structure, the voltage regulation coil TAP is forward and reverse, and the common coil COM is an end outlet. The three-phase common coil COM The end is connected to the neutral point HOXO. The arrangement of the coils is: iron core-common coil-voltage regulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com