Radiator for thyristor element and electric locomotive rectifier

A heat sink and silicon component technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as adding more aluminum heat sinks or increasing the area, insufficient heat dissipation of thyristor components, and long distances for heat conduction. To achieve the effect of short heat transfer path, light weight and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

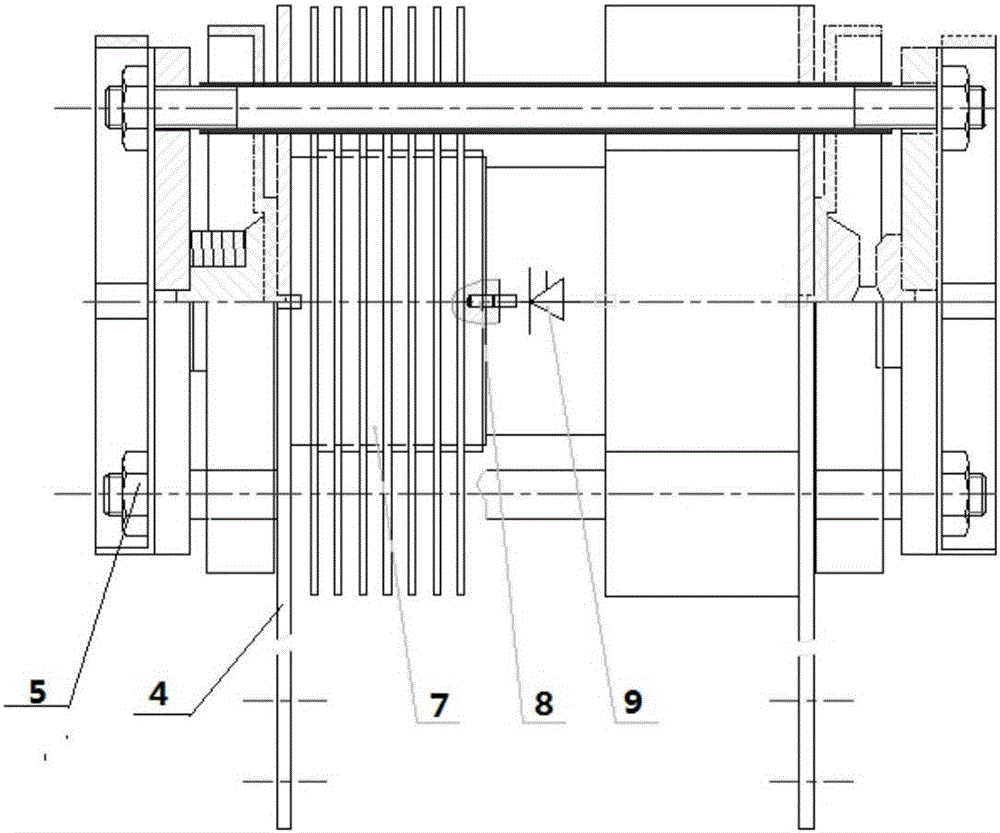

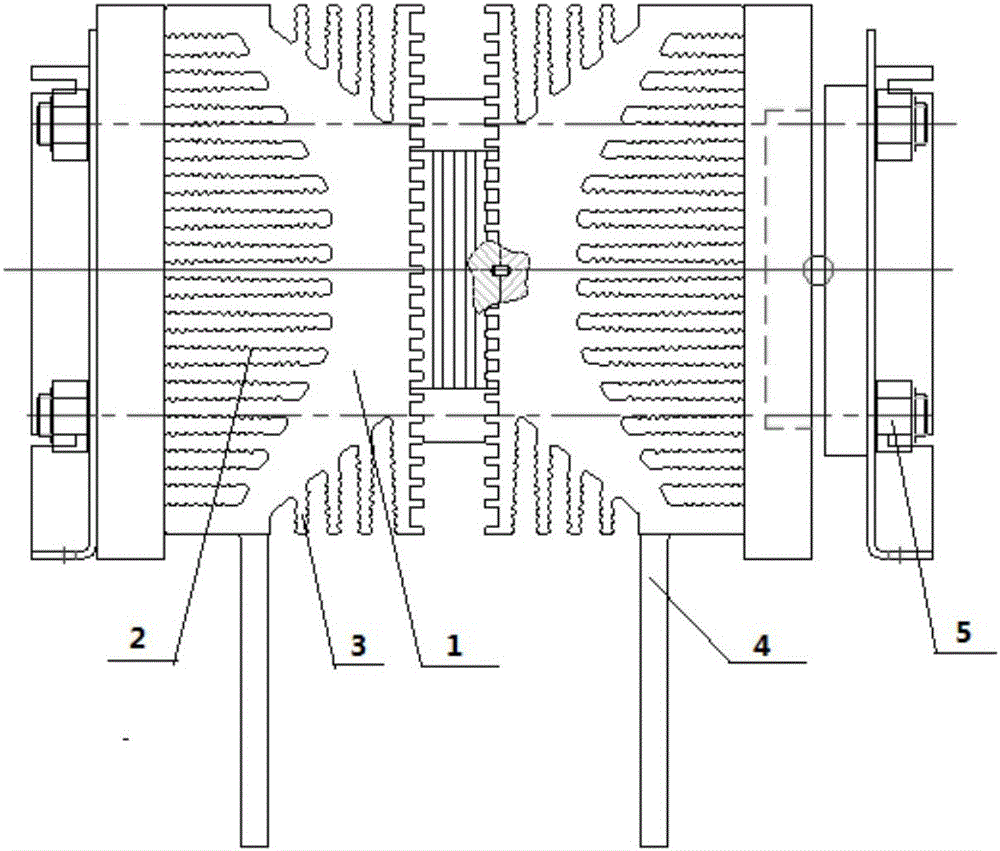

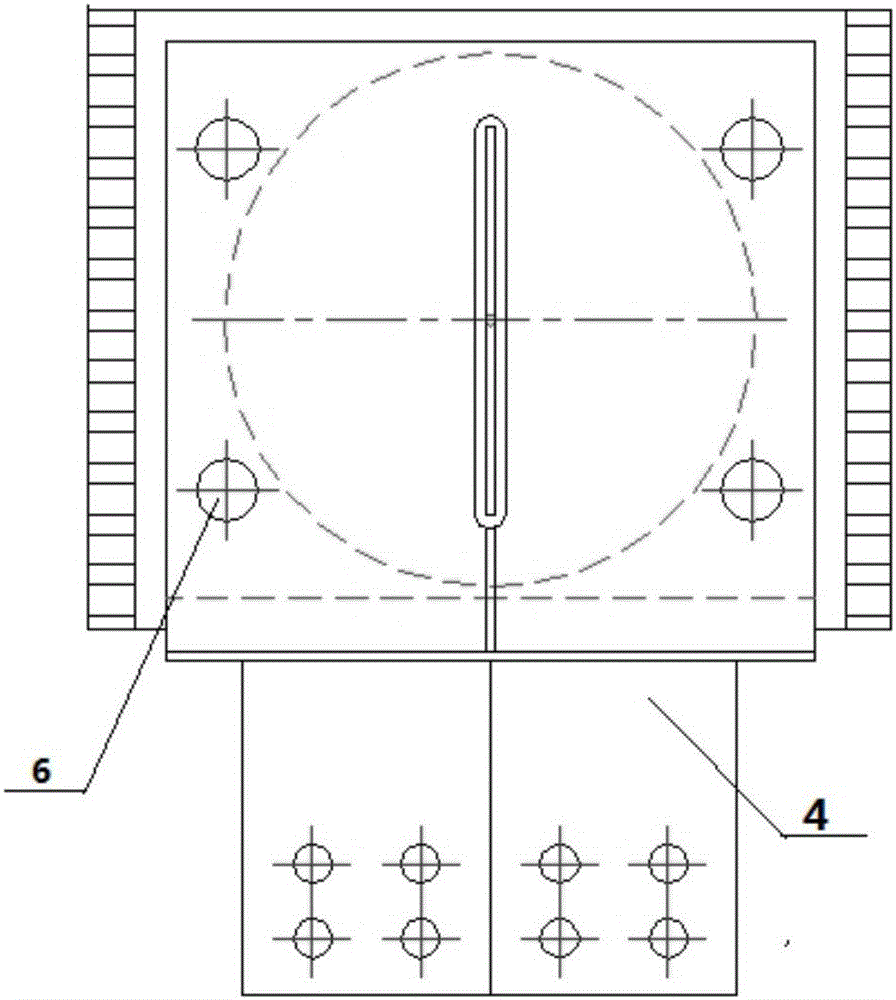

[0035] Such as Figure 2 to Figure 4As shown, the heat sink for thyristor element according to the present invention may include frame 1 , main heat sink 2 and side heat sink 3 . The frame 1 may include a base 13 and a plurality of legs protruding from a first side surface 131 of the base. The plurality of leg portions may include two end leg portions 12 adjacent to both ends of the first side surface 131, and the second side surface 132 of the base portion 13 opposite to the first side surface 131 may be used to communicate with the thyristor. component contacts. A plurality of main cooling fins 2 extend from the frame 1 in a direction away from the base 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com