Preparation method of built-in carbon fiber electric-heating laminate flooring and wooden floor thereof

A technology of laminate flooring and preparation process, which is applied in electric heating systems, wood-layered products, lighting and heating equipment, etc., can solve the problems of high heat loss, easy aging of heating elements, slow heating up, etc. Good convection effect and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

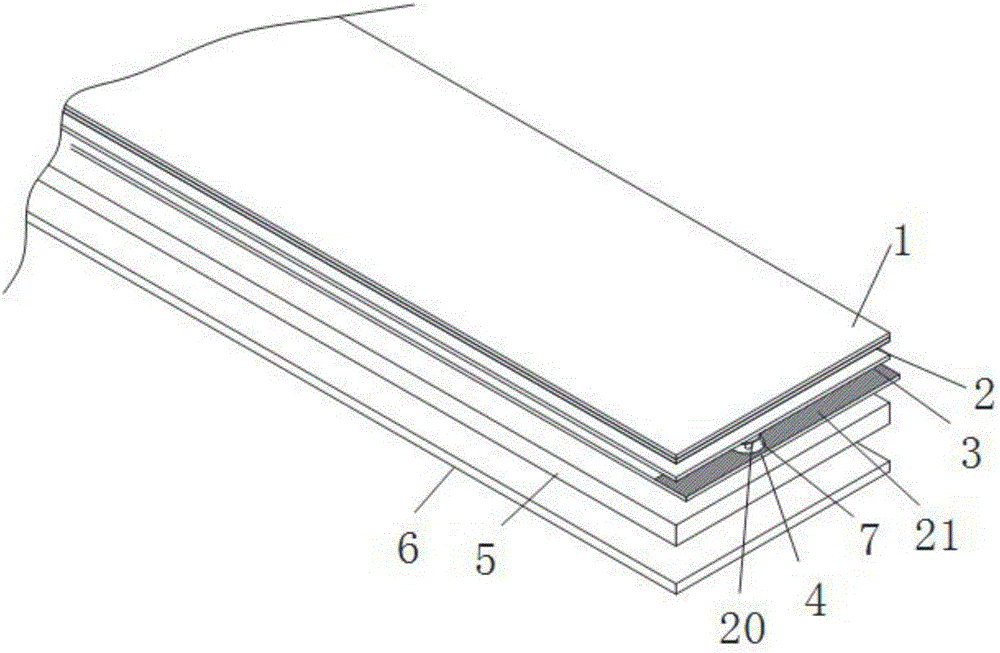

[0029] Embodiment 1: The preparation process of the reinforced floor with built-in carbon fiber electric heating layer specifically includes the following steps:

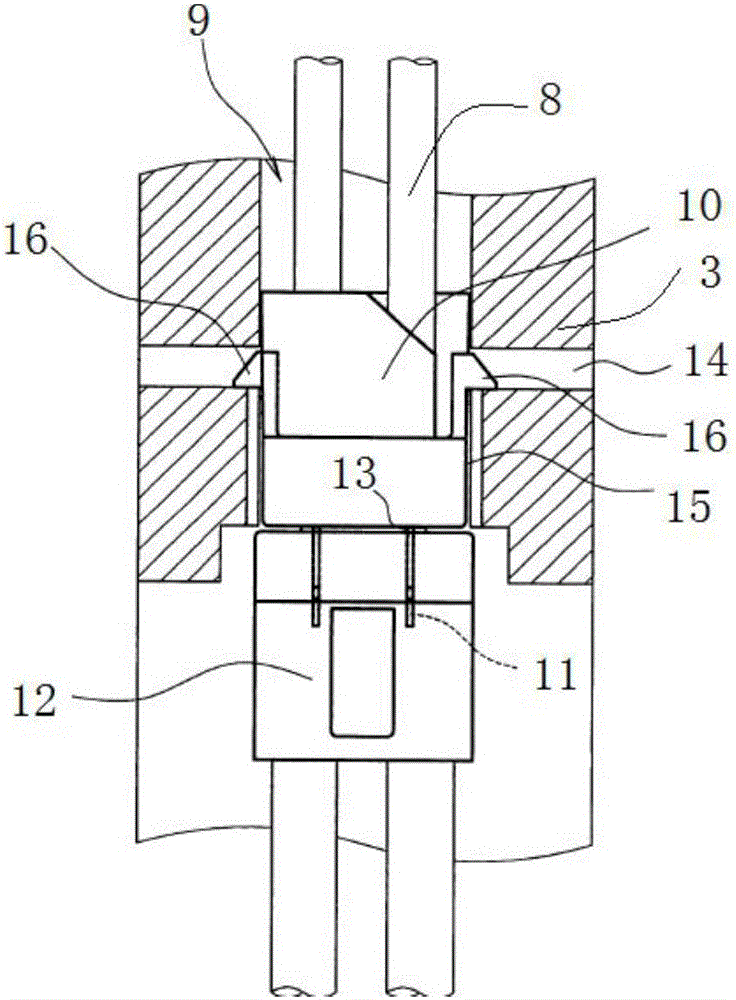

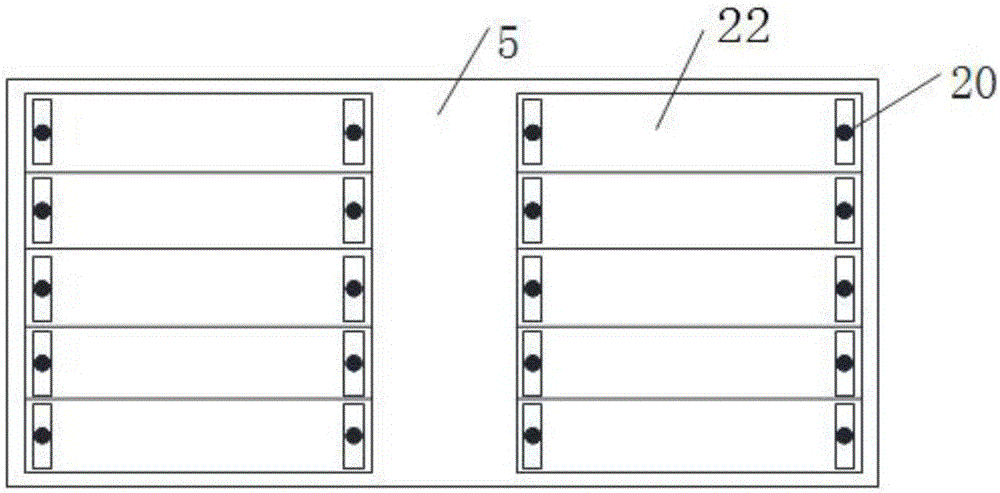

[0030] (1) Carry out marking, positioning, and punching on the high-density fiberboard base material in sequence according to the floor width and calorific value requirements; then apply glue on the surface of the high-density fiberboard base material, and the amount of glue is 250-300g / m 2 , install conductive copper electrodes, and paste multiple carbon fiber heating paper on the surface of the high-density fiberboard substrate according to the hole position;

[0031] (2) hot pressing and pasting balancing paper on the back of the high-density fiberboard substrate;

[0032] (3) Hot-press wood grain decorative paper and wear-resistant paper on the surface of the high-density fiberboard veneer in sequence, heat-press at a temperature of 190 ° C and a pressure of 18 MPa for 35 seconds, and then apply glue on the back...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com