Reconstituted tobacco coating quantity on-line detection control system and control method

A technology for detection and control system and reconstituted tobacco leaves, which is applied in general control system, control/regulation system, program control, etc., can solve problems such as inability to reflect the instantaneous change of coating amount, heavy detection workload, and long detection cycle, etc., to achieve The effect of reducing manual sampling frequency, improving operation stability, and improving quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

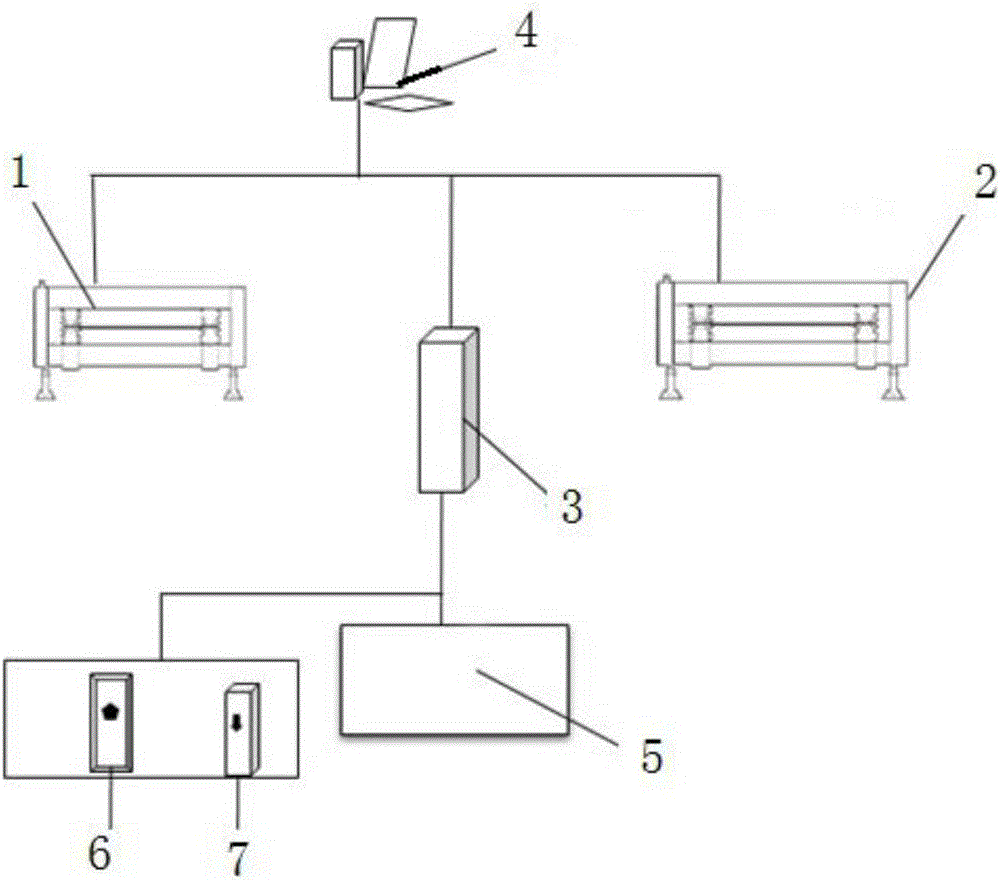

[0016] like figure 1 The online detection and control system for coating amount of reconstituted tobacco leaves as shown includes scanning frame 1 before coating, scanning frame 2 after coating and its control cabinet 3, vehicle speed signal sensor 6, paper breaker, etc. Signal sensor 7, QCS operation station 4 connected to the scanning frame before coating and scanning frame after coating, server 5 for information exchange with control cabinet 3, QCS operation station 4, vehicle speed signal sensor 6, and paper break signal sensor 7 ; By scanning frame 1 before coating and scanning frame 2 after coating, the absolute dry weight of the substrate before coating and the absolute dry weight of reconstituted tobacco leaves after coating are detected, the coating amount is calculated, and the coating amount of reconstituted tobacco leaves is carried out on-line Detection control. The information interaction between the QCS operation station 4 and the scanning frame 1 before coatin...

Embodiment 2

[0024] 1) Detect the absolute dry weight of the film base: the operator opens the pre-coating scanning frame through the QCS operation station and the control cabinet, and when the film base passes the pre-coating scanning frame, the pre-coating scanning frame can detect the absolute dry weight of the film base 59g / m 2 ;

[0025] 2) Detect the absolute dry quantity of reconstituted tobacco leaves after coating: start the scanning frame after coating, obtain the real-time speed of the paper machine through the speed signal sensor, and send the data to the server, and the server sends the scanning frame and the pre-coating frame according to the calculated synchronization time difference After coating, the scanning frame sends out a synchronization command, and the scanning frame after coating acts as a slave frame to follow the scanning frame before coating to scan according to the synchronization command. During operation, the server will use the reverse edge time of the opera...

Embodiment 3

[0029] 1) Detect the absolute dry quantity of the film substrate before coating: the operator opens the pre-coating scanning frame through the QCS operation station and the control cabinet, and when the film substrate passes the pre-coating scanning frame, the pre-coating scanning frame can detect the The absolute dry weight is 61g / m 2 ;

[0030] 2) Detect the absolute dry quantity of reconstituted tobacco leaves after coating: start the scanning frame after coating, obtain the real-time speed of the paper machine through the speed signal sensor, and send the data to the server, and the server sends the scanning frame and the pre-coating frame according to the calculated synchronization time difference After coating, the scanning frame sends out a synchronization command, and the scanning frame after coating acts as a slave frame to follow the scanning frame before coating to scan according to the synchronization command. During operation, the server will use the reverse edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com