Membrane filtration unit and membrane assembly

A filtration unit, membrane filtration technology, applied in membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problems of shortening the service life of the membrane stack, aggravating the pollution degree of the membrane, reducing the water treatment efficiency, etc., and increasing the contact area. , the structure is simple, the effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

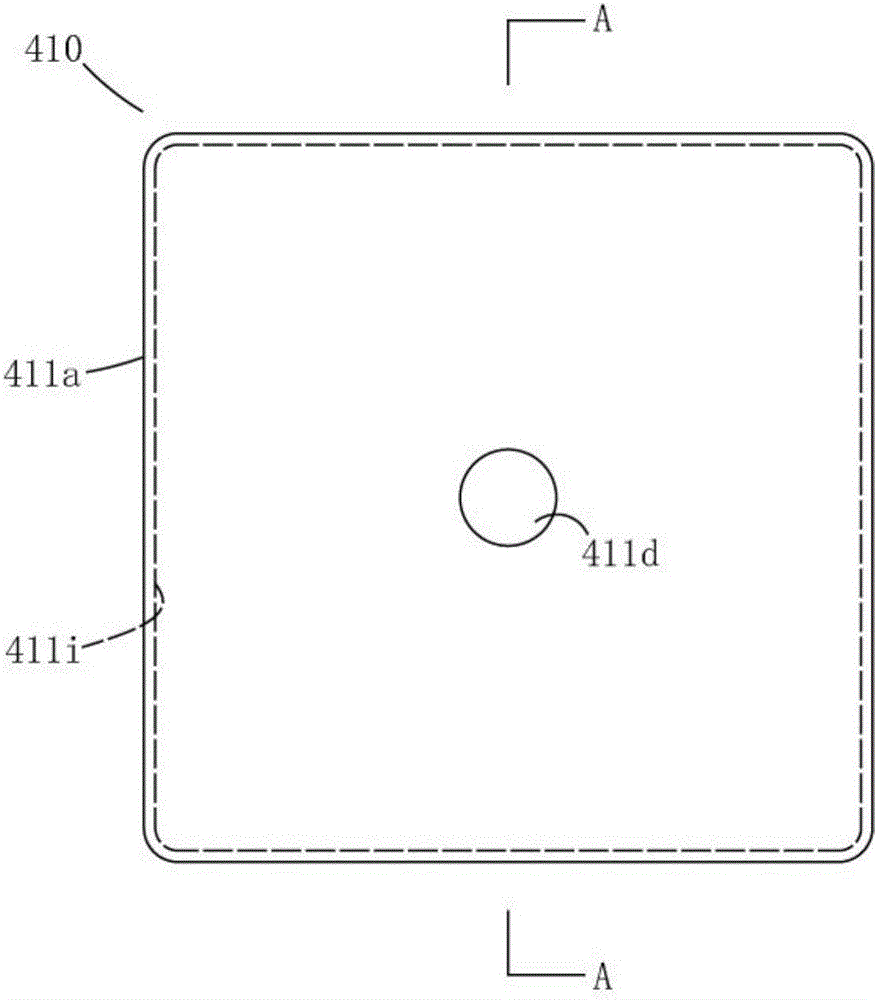

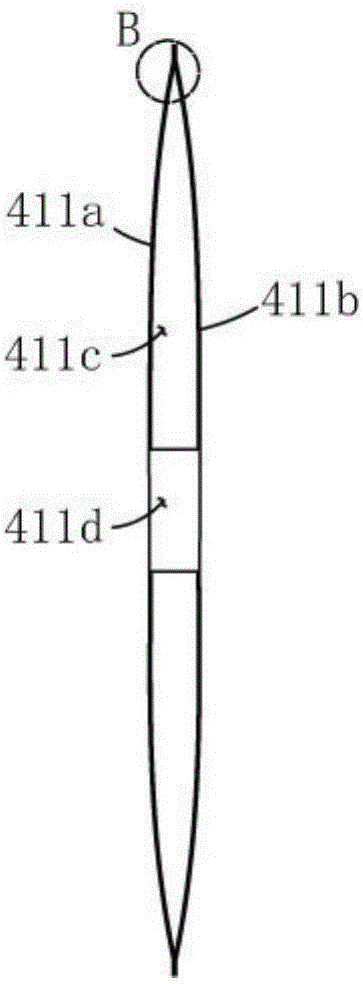

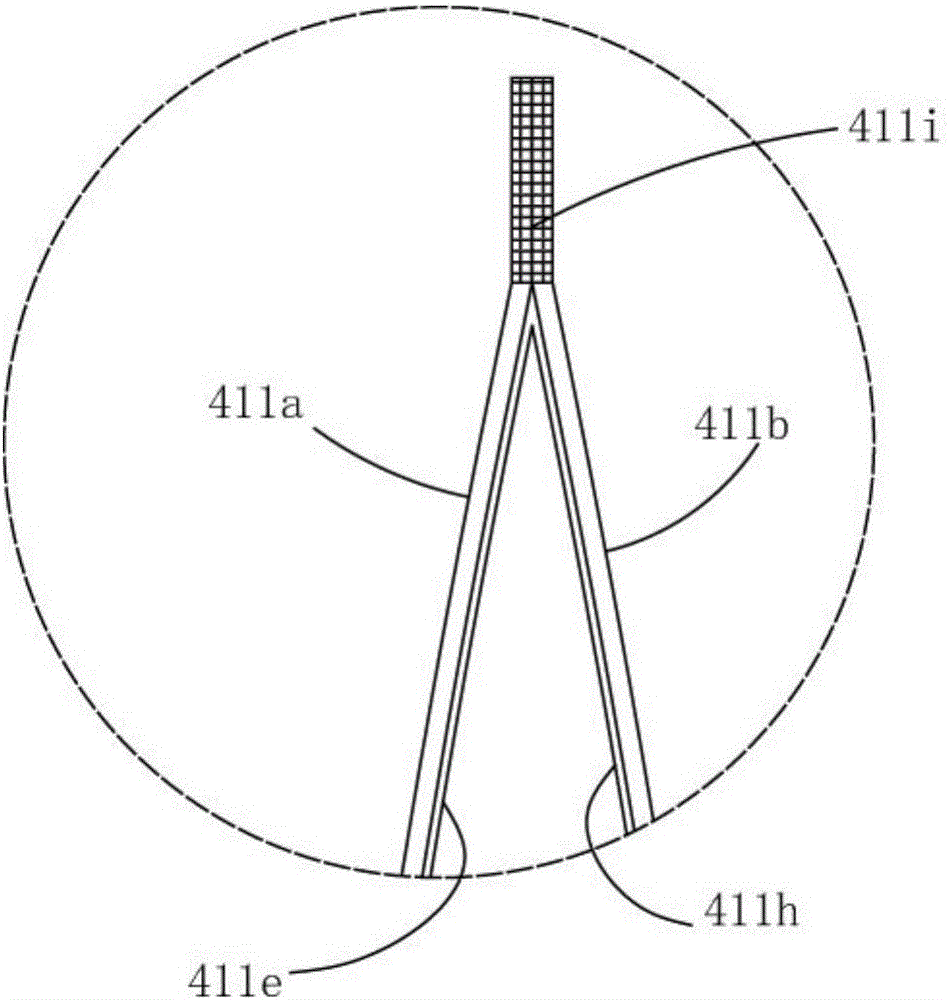

[0026] Such as Figure 1-3 As shown, the membrane filtration unit 410 includes an upper filter membrane 411a, a lower filter membrane 411b, an upper support net 411e for supporting the upper filter membrane 411a and a lower support net 411h for supporting the lower filter membrane 411b, the upper support net 411e and the lower support net 411b. A cavity 411c is formed between the support nets 411h, and the center of the membrane filtration unit 410 is provided with an installation through hole 411d passing through the upper filter membrane 411a, the upper support net 411e, the lower filter membrane 411b and the lower support net 411h. The outer edges of the upper filter membrane 411a, the lower filter membrane 411b, the upper support net 411e and the lower support net 411h are superimposed and welded to form a closed perimeter 411i, and the width of the closed perimeter 411i is 5mm. The upper support net 411e and the lower support net 411h are stainless steel screens with a me...

Embodiment 2

[0029] Such as Figure 5-8As shown, the membrane filtration unit 410 includes an upper filter membrane 411a, a lower filter membrane 411b, an upper support net 411e for supporting the upper filter membrane 411a and a lower support net 411h for supporting the lower filter membrane 411b, the upper support net 411e and the lower support net 411b. A cavity 411c is formed between the support nets 411h, and the center of the membrane filtration unit 410 is provided with an installation through hole 411d passing through the upper filter membrane 411a, the upper support net 411e, the lower filter membrane 411b and the lower support net 411h. The outer edges of the upper filter membrane 411a, the lower filter membrane 411b, the upper support net 411e and the lower support net 411h are superimposed and welded to form a closed perimeter 411i, and the width of the closed perimeter 411i is 30mm. The upper support net 411e and the lower support net 411h are stainless steel screens with a me...

Embodiment 3

[0032] Compared with Embodiment 2, the membrane filtration unit of this embodiment has the following differences: the width of the closed periphery 411i is 55mm; the upper support net 411e and the lower support net 411h are stainless steel screens with a mesh size of 40 mesh and a thickness of 2mm; the thickness of the support plate 411f is 0.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com