Catalyst for catalytic coal gasification as well as catalytic coal gasification method and device

A technology for coal catalytic gasification and catalyst, which is applied in the field of coal catalytic gasification, can solve the problems affecting the economical efficiency of coal catalytic gasification, high cost, high water consumption and energy consumption, and achieves overcoming the difficulty of ash and slag separation. The effect of recycling is convenient and fast, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

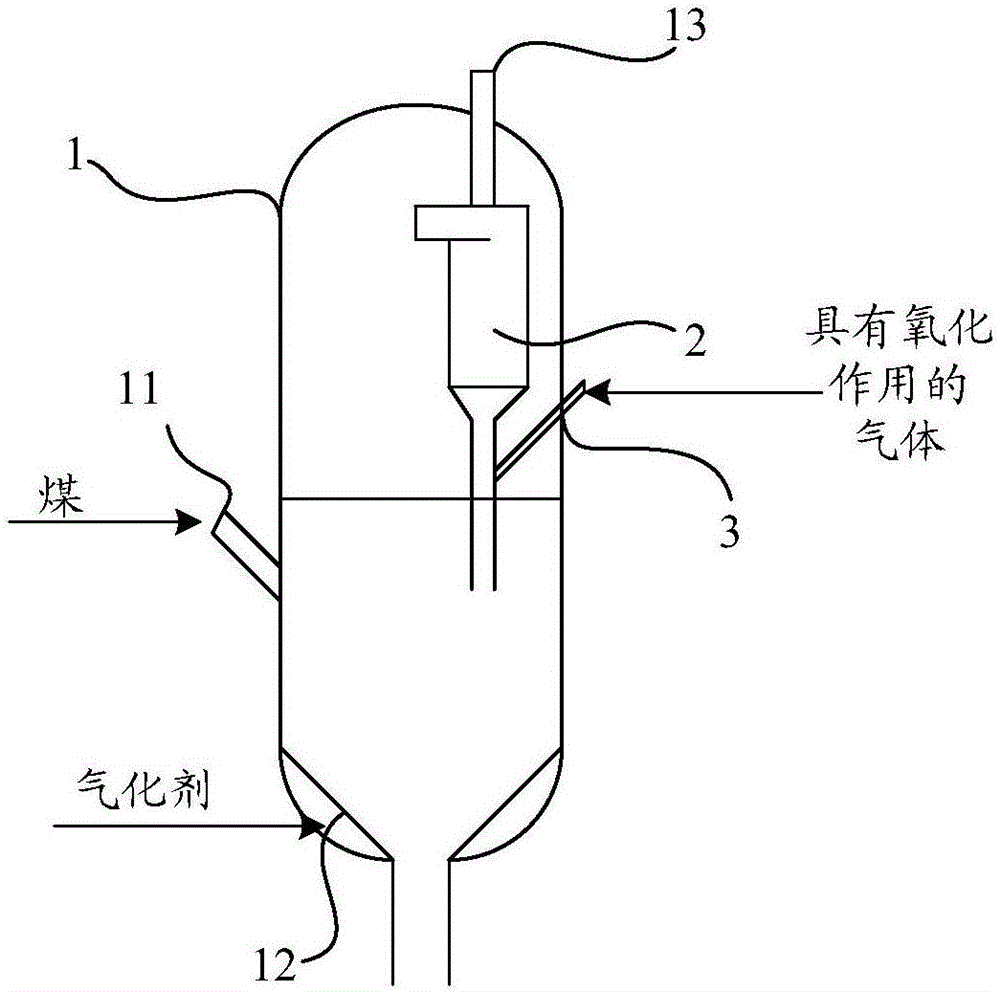

[0028] A catalyst for catalytic coal gasification and a method and device for catalytic coal gasification provided by embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] On the one hand, an embodiment of the present invention provides a catalyst for catalytic coal gasification, including:

[0030] Methanation active ingredients and oxygen carriers;

[0031] The oxygen-carrying agent includes: an oxygen-carrying compound and a carrier; wherein, the oxygen-carrying compound is selected from one or more of copper oxide, nickel oxide, manganese oxide and cobalt oxide.

[0032] Wherein, it should be noted that when the oxygen-carrying compound is nickel oxide or / and cobalt oxide, although it itself has a certain methanation activity, its methanation activity is low, and by adding additional methanation activity Components, capable of forming a catalyst with methanation activity (mainly methanation active co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com