Blind hole rectangular spline cold extrusion forming method

A molding method and cold extrusion technology, applied in metal extrusion dies, metal processing equipment, etc., can solve the problems of reducing product service life, destroying metal streamline structure, and long processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

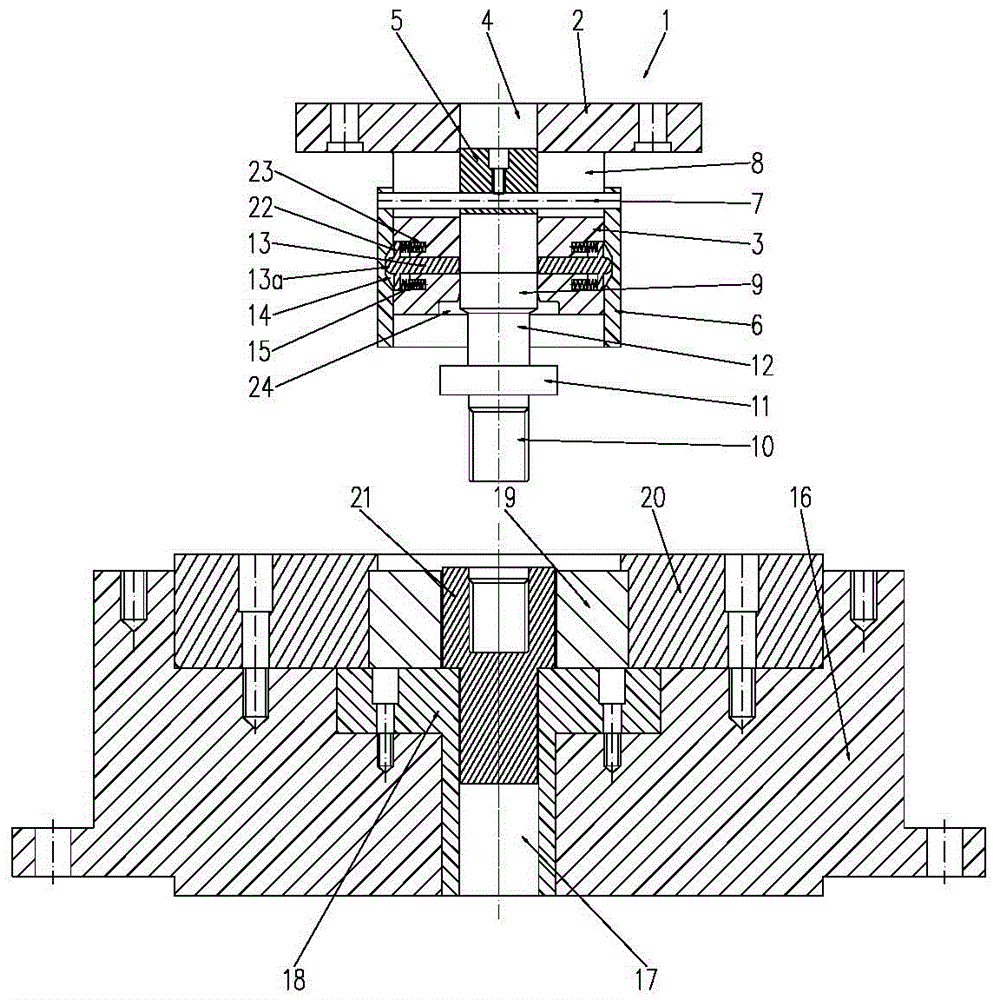

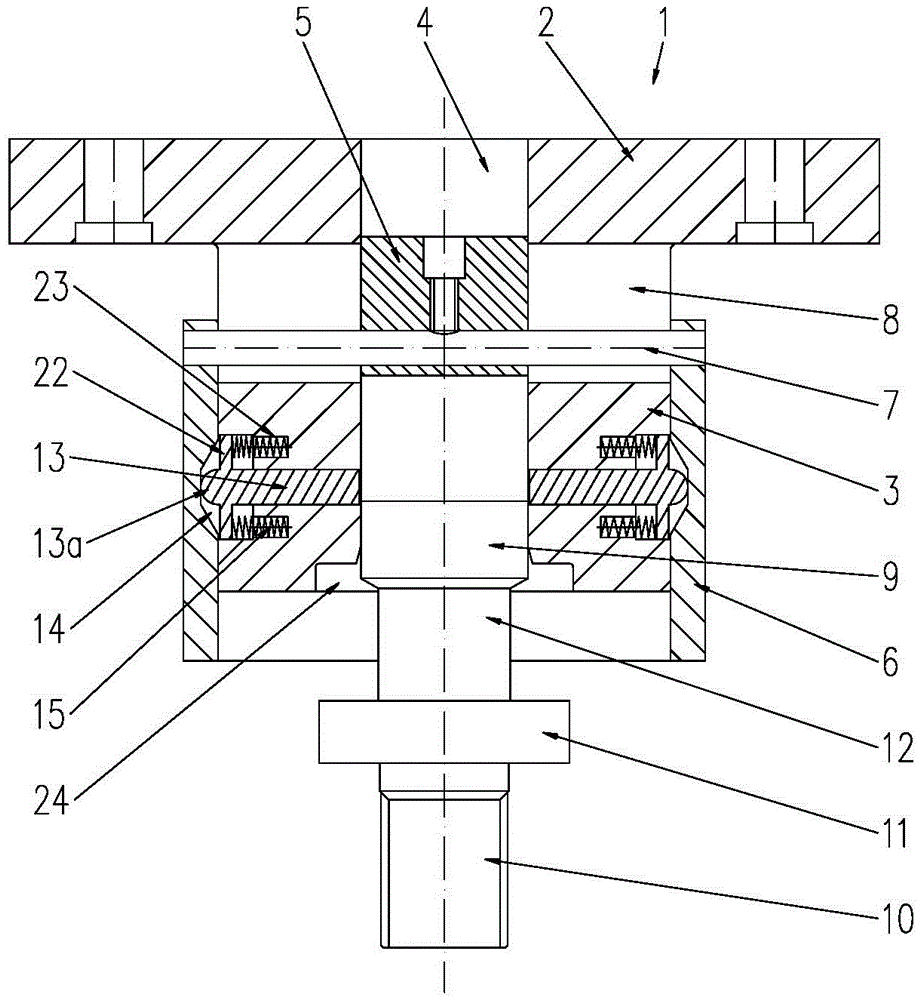

[0027] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples cited are not intended to limit the present invention.

[0028] In the method for cold extrusion molding of blind hole rectangular splines of this embodiment, the processing steps are: blanking→heating→pier billet→hot forging rough forming→normalizing→shot blasting→surface treatment→cold extrusion molding;

[0029] Among them, in the heating process, after the billet is heated to 1100°C, the billet is made to reduce its deformation resistance and prevent overheating and overburning, and then use the punch blank;

[0030] In the hot forging rough forming process, a friction press or an electric screw press is used to hot forge the blank to make the blank reach the required rough state;

[0031] In the normalizing process, the continuous mesh belt mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com