Tundish

A tundish and shell technology, applied in the field of tundish, can solve the problems of poor flow stabilization effect, complicated design, troublesome disassembly and assembly of slag retaining wall, etc., and achieve the effect of high diversion effect, simple structure and high resistance to slag erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

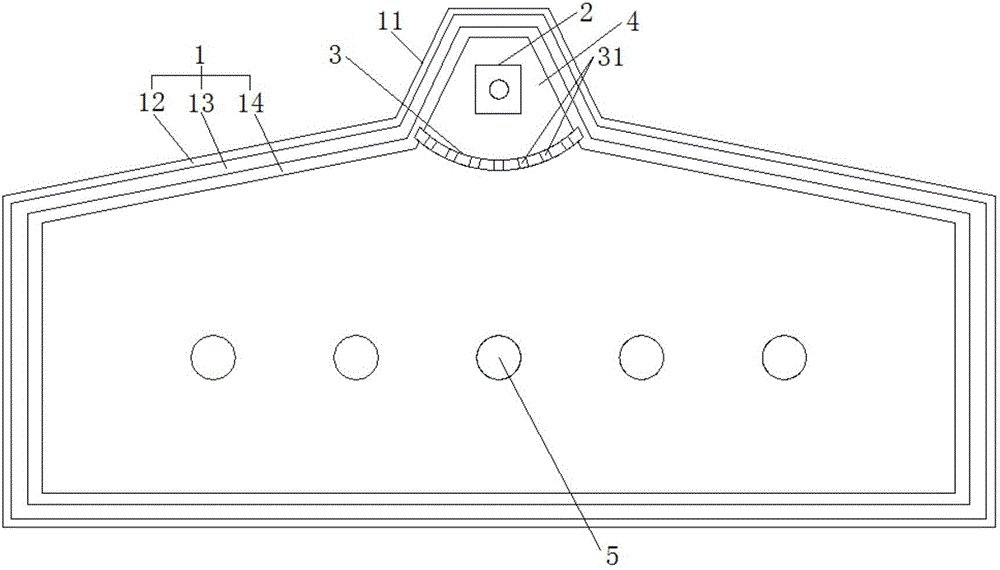

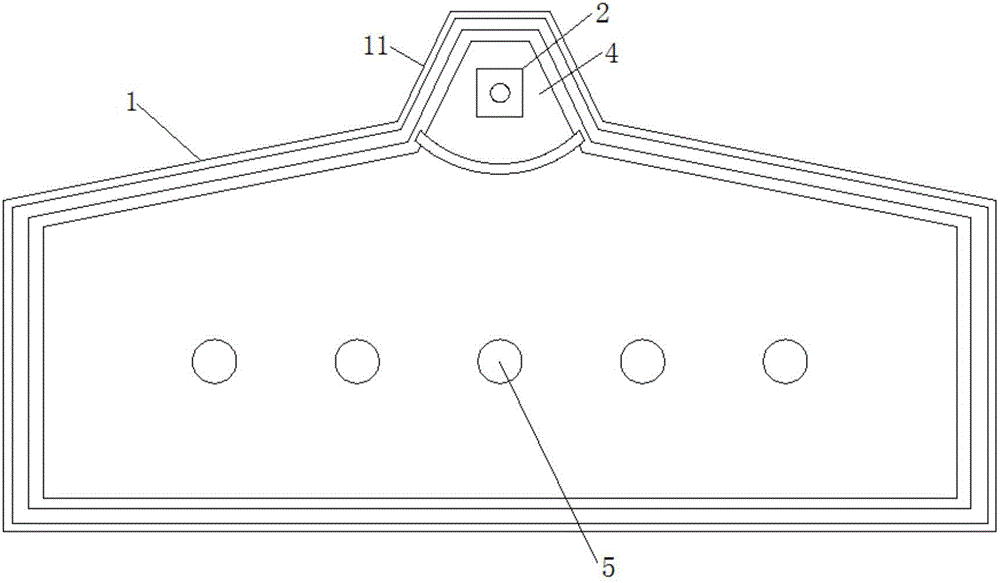

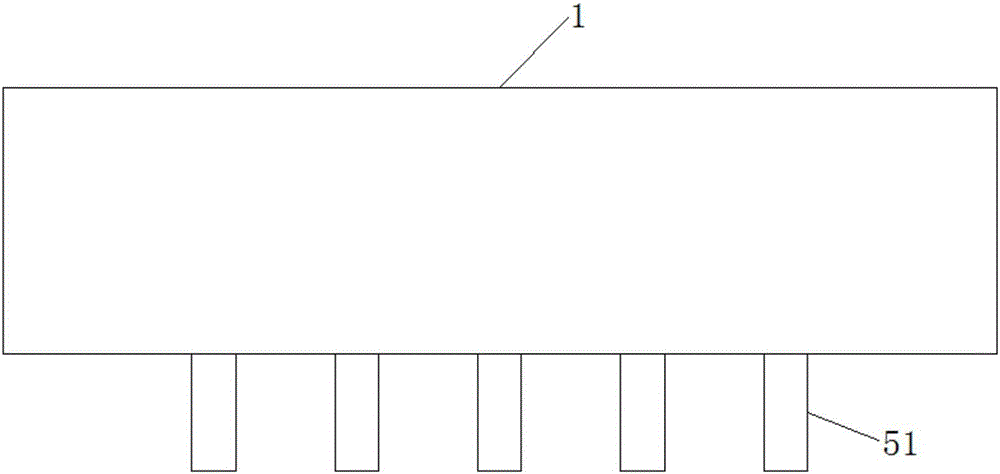

[0031] Example: such as Figures 1 to 3 As shown, the tundish of this embodiment includes a tundish shell 1, a tundish impact barrel 2, and a slag retaining wall 3. The above-mentioned tundish shell 1 is a shell structure with an open top, and the above-mentioned tundish impact barrel 2 is arranged in the middle On the inner bottom wall of the tundish shell 1 and set close to the side wall of the tundish shell 1, the above-mentioned slag retaining wall 3 is vertically set, and its two ends and the bottom are respectively embedded on the inner wall and the bottom wall of the tundish shell 1 , an impact area 4 is formed between the above-mentioned slag retaining wall 3 and the above-mentioned tundish shell 1, the above-mentioned tundish impact barrel 2 is located in the above-mentioned impact area 4, and the bottom wall of the above-mentioned tundish shell 1 is provided with a plurality of middle Bag water outlet 5.

[0032] The side wall of the tundish shell 1 protrudes outwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com