Rare-earth powder high-pressure forming system

A technology of high-pressure molding and rare earth powder, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of small flatness of product shape, unreachable mold release rate, and reduced blank utilization rate, etc., to achieve Low risk of technological transformation, reduced nitrogen consumption, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

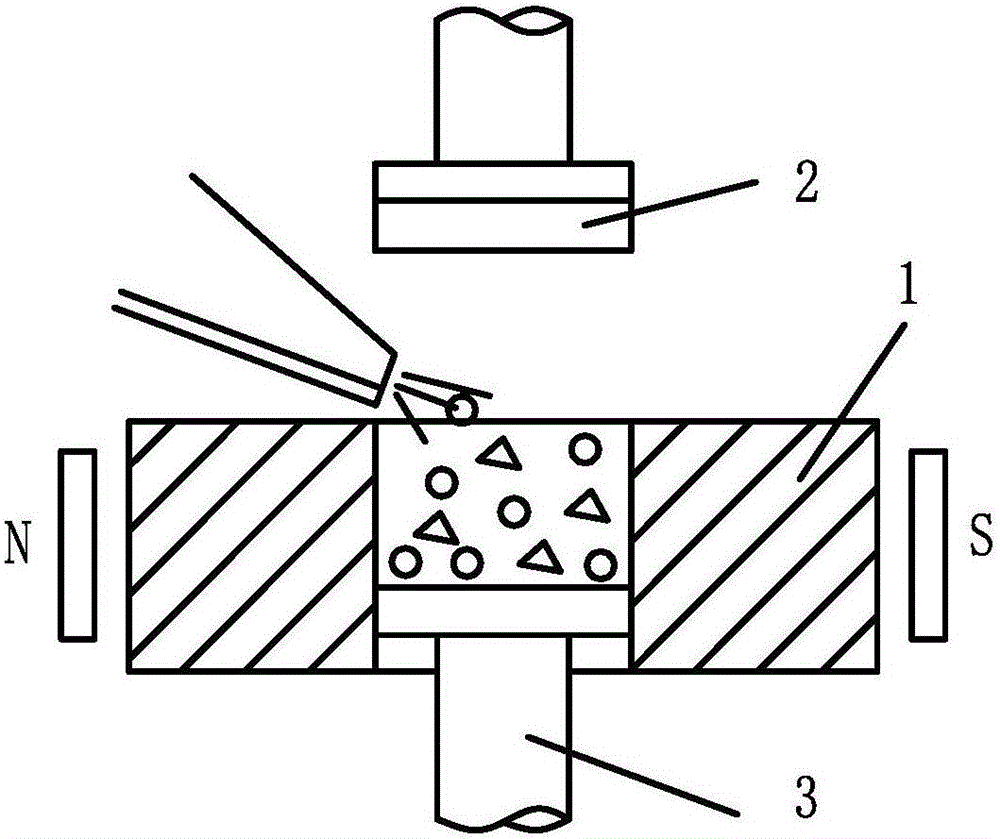

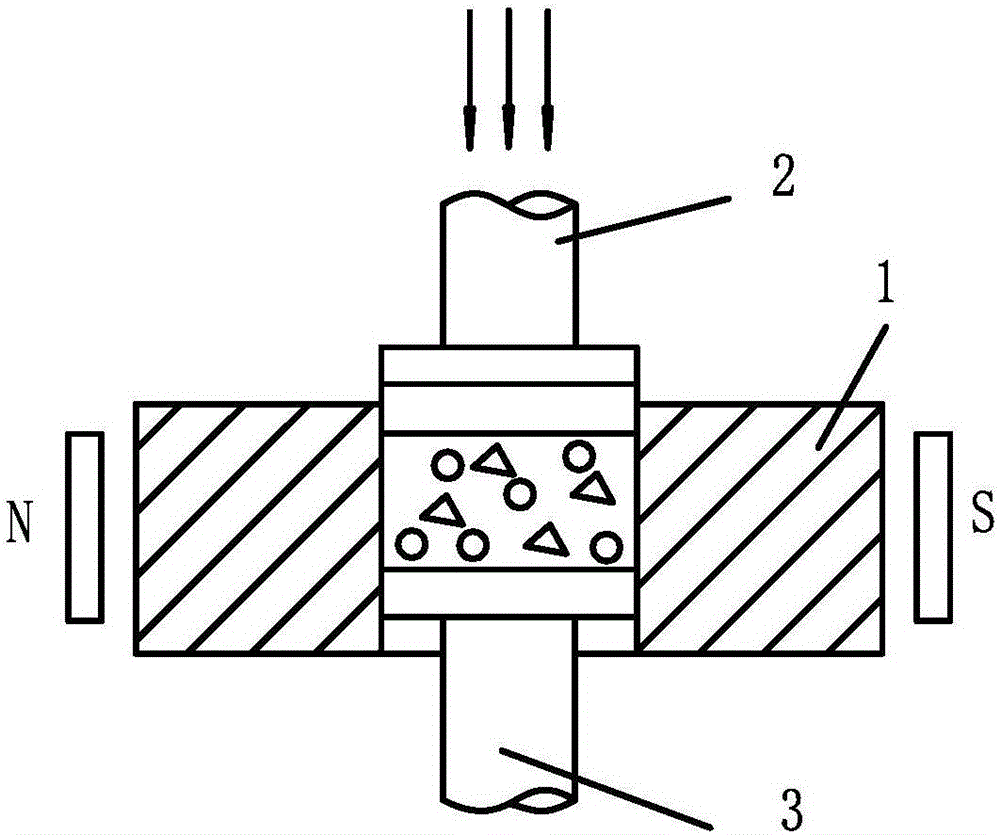

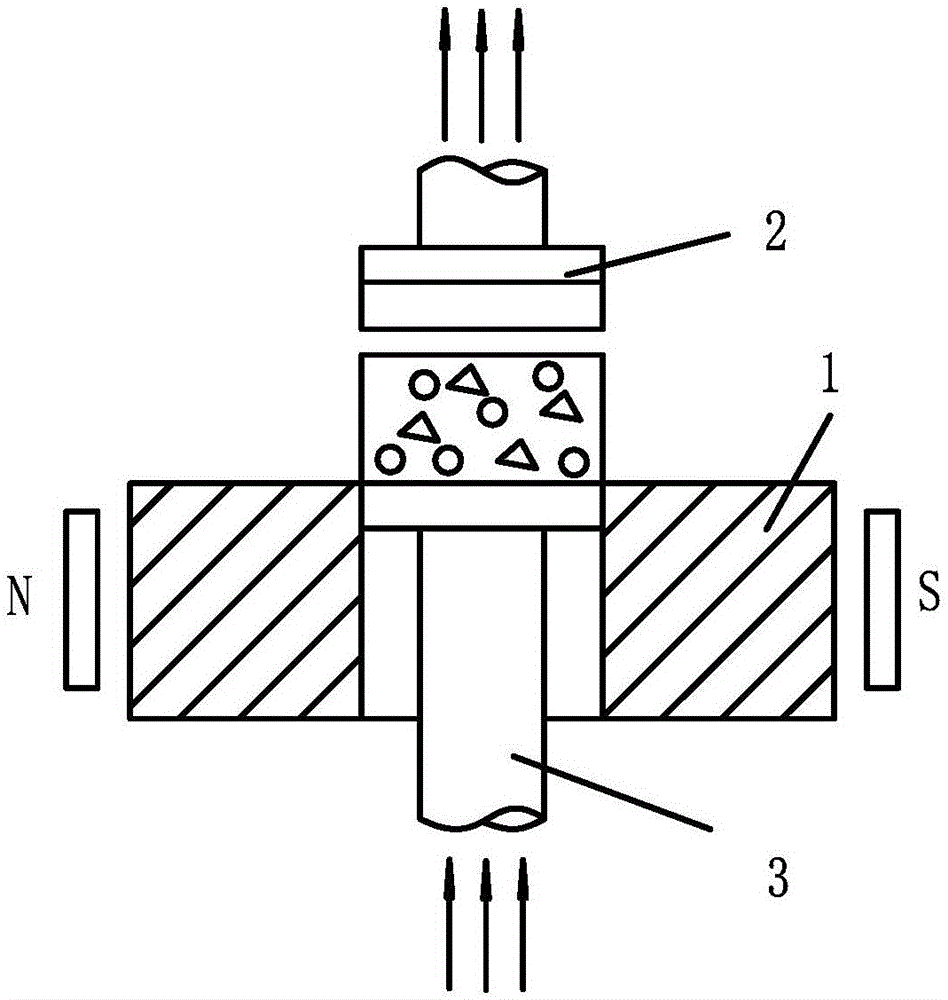

[0035] like Figure 1 to Figure 3 As shown, it is a schematic diagram of the mold pressure forming process in the prior art, which includes filling, molding, and mold release in sequence. like figure 1 Feeding and pressing as shown, the powder is filled into the die 1, and the surface of the powder is smoothed with a special scraper. like figure 2 The electromagnetic poles on both sides of the concave die 1 shown are energized to orientate the magnetic poles of the powder, and the punch 2 descends at the same time to generate high pressure with the discharge top plate to press the powder into shape. like image 3 The finished product shown in the figure is out of the mold, and the base plate 3 of the die and the punch 2 rise synchronously, and the whole process maintains an equal distance. The punch 2 always keeps in contact with the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com