Method for sintering ash through mechanical hot-pressing coupling

A technology of sintering ash and mechanical pressurization, which is applied in the fields of solid waste removal, recycling technology, construction waste recycling, etc., can solve the problems of difficult ash treatment such as high processing temperature, and achieve reduction of secondary pollution, energy consumption, The effect of lowering the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

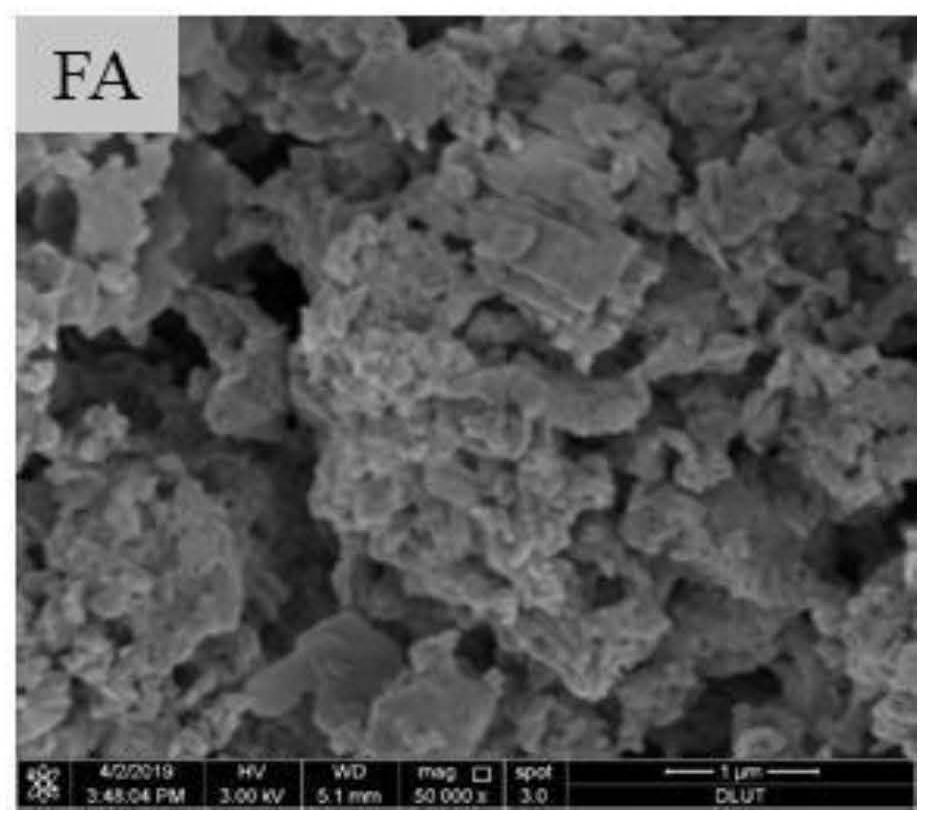

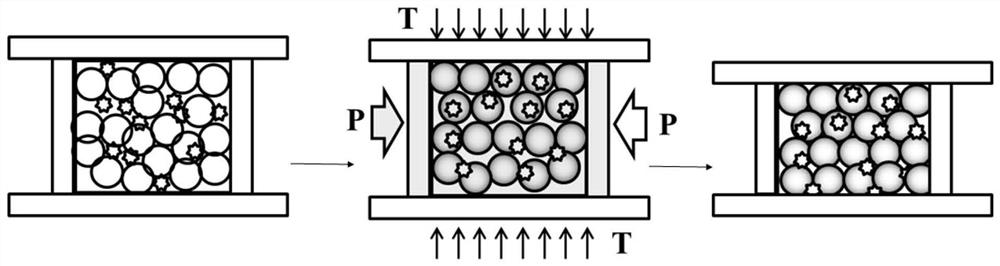

[0026] Example 1: Place the fly ash in an oven at 105°C to dry to constant weight. In order to ensure the uniform particle size of the fly ash in the follow-up experiments, this experiment uses a 100-mesh sieve to sieve the fly ash and put it in a ziplock bag for later use. . Weigh 5.0 g of the sieved fly ash and put it into a mold (20 mm in diameter) of a thermocompression coupled sintering device. When carrying out the experiment, first set the target pressure of 10MPa, and control the punch on the upper part of the pressure sensor through the computer. The punch drops at a speed of 1mm / min under the control of the computer to apply pressure to the reaction chamber. When the target pressure is reached, keep the set pressure. Set a certain pressure, and start to raise the temperature to the target temperature of 400 °C at a rate of 10 °C / min, keep the pressure at the target temperature for 1 hour, stop heating, and release the pressure through the computer control pressure se...

Embodiment 2

[0027] Example 2: Place the fly ash in an oven at 105°C to dry until constant weight. In order to ensure uniform particle size of the fly ash in subsequent experiments, this experiment uses a 100-mesh sieve to sieve the fly ash and put it in a ziplock bag for later use. . Weigh 5.0 g of the sieved fly ash and put it into a mold (20 mm in diameter) of a thermocompression coupled sintering device. When conducting experiments, first set the target pressure of 50MPa, and control the punch on the upper part of the pressure sensor through the computer. The punch drops at a speed of 1mm / min under the control of the computer to apply pressure to the reaction chamber. When the target pressure is reached, keep the set pressure. Set a certain pressure, and start to raise the temperature to the target temperature of 400 °C at a rate of 10 °C / min, keep the pressure at the target temperature for 1 hour, stop heating, and release the pressure through the computer control pressure sensor. Sa...

Embodiment 3

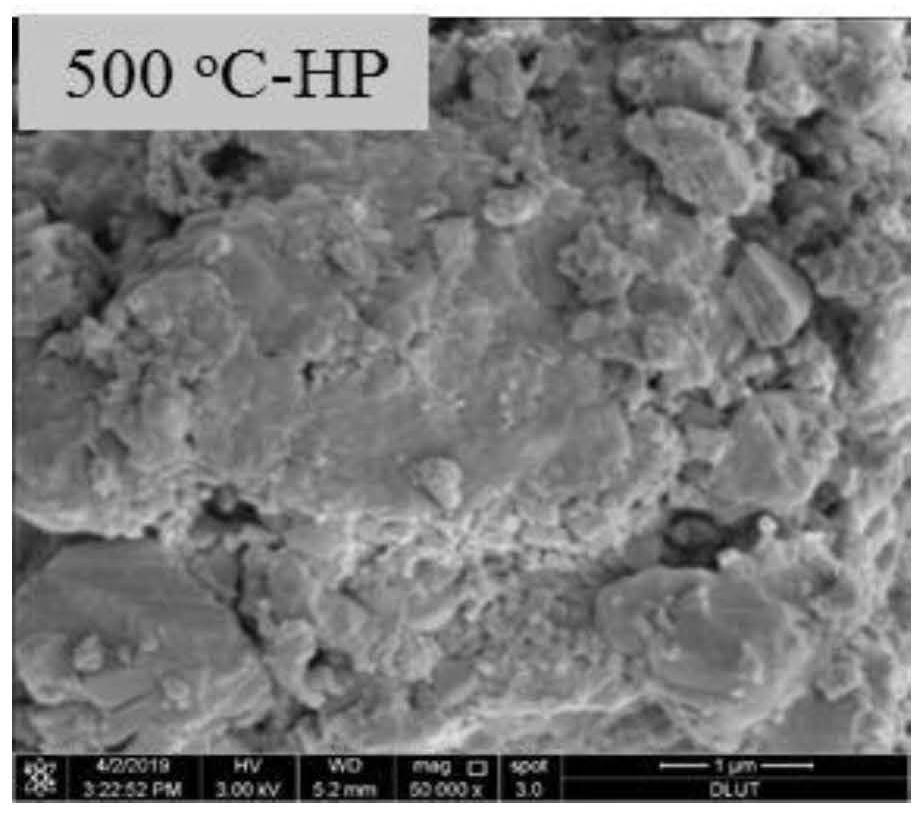

[0028] Example 3: Place the fly ash in an oven at 105°C and bake to constant weight. In order to ensure the uniform particle size of the fly ash in the subsequent experiments, this experiment uses a 100-mesh sieve to sieve the fly ash and put it in a ziplock bag for later use . Weigh 5.0 g of the sieved fly ash and put it into a mold (20 mm in diameter) of a thermocompression coupled sintering device. When conducting the experiment, first set the target pressure of 100MPa, and control the punch on the upper part of the pressure sensor through the computer. The punch drops at a speed of 1mm / min under the control of the computer to apply pressure to the reaction chamber. When the target pressure is reached, keep the set pressure. Set a certain pressure, and start to raise the temperature to the target temperature of 500 °C at a rate of 10 °C / min, keep the pressure at the target temperature for 1 hour, stop heating, and release the pressure through the computer control pressure s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com