Submerged-arc welding deep penetration single-side welding technology of thick plates

A single-sided welding and submerged arc welding technology, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of many welding passes, low welding efficiency and large amount of welding consumables in manual working hours, so as to reduce labor and welding costs. The effect of material cost, improvement of welding efficiency, and less welding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Welding steel plates with a thickness of 35mm or less includes the following steps:

[0048] S1, cutting the groove of the steel plate to be welded;

[0049] S2. Splicing two steel plates with grooves with V-shaped grooves and fixing them on the backing plate, the included angle of the V-shaped grooves is 45°, and the gap between the bottoms of the two grooves is 0-5mm;

[0050] S3, fixed-point welding in the groove, the distance between adjacent fixed points is 1m, and the length of each fixed point is 50mm;

[0051] S4. Welding with double welding wire matching sintering flux technology, the diameter of any welding wire is 5mm, the front welding wire and the rear welding wire are arranged along the welding direction, the angle between the front welding wire and the backing plate is 75°, the front welding wire The vertical distance between the welding wire and the backing plate is 35cm, the front welding wire is welded by direct current, the current of the direct curr...

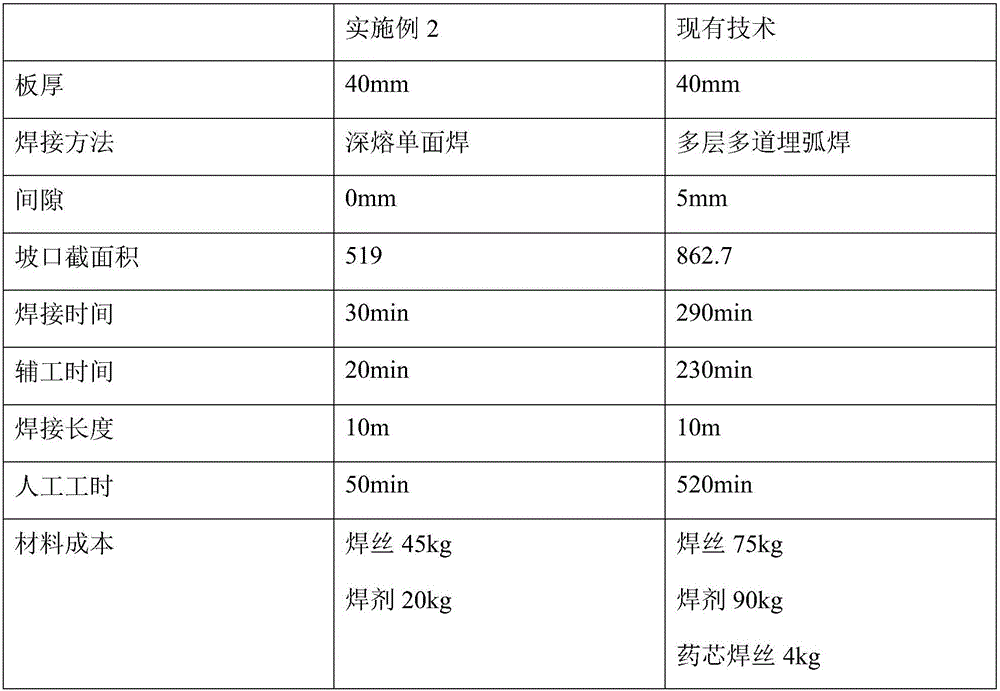

Embodiment 2

[0053] Welding a steel plate with a thickness of 40mm includes the following steps:

[0054]S1, cutting the groove of the steel plate to be welded;

[0055] S2. Splicing two steel plates with grooves with V-shaped grooves and fixing them on the backing plate, the included angle of the V-shaped grooves is 45°, and the gap between the bottoms of the two grooves is 0-5mm;

[0056] S3, fixed-point welding in the groove, the distance between adjacent fixed points is 1m, and the length of each fixed point is 50mm;

[0057] S4, welding is carried out by adopting the process of double welding wire matching sintering flux, the diameter of any welding wire is 6.4mm, and the front welding wire and the rear welding wire are arranged along the welding direction, and the angle between the front welding wire and the backing plate is 75°, the described The vertical distance between the front welding wire and the backing plate is 35cm, and the front welding wire is welded by direct current. T...

Embodiment 3

[0063] Welding a steel plate with a thickness of 50mm includes the following steps:

[0064] S1, cutting the groove of the steel plate to be welded;

[0065] S2. Splicing two steel plates with grooves with V-shaped grooves and fixing them on the backing plate, the included angle of the V-shaped grooves is 45°, and the gap between the bottoms of the two grooves is 0-5mm;

[0066] S3, fixed-point welding in the groove, the distance between adjacent fixed points is 1m, and the length of each fixed point is 50mm;

[0067] S4, welding is carried out by adopting the process of double welding wire matching sintering flux, the diameter of any welding wire is 6.4mm, and the front welding wire and the rear welding wire are arranged along the welding direction, and the angle between the front welding wire and the backing plate is 75°, the described The vertical distance between the front welding wire and the backing plate is 35cm, the front welding wire is welded by direct current, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com