General roof bend beam clamp used or laser cutting technology

A technology of laser cutting and bending beams, which is applied in the direction of manufacturing tools, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of excessive extrusion of bending beams, affect the accuracy of laser cutting processing, and high cost, so as to improve precision and expand The effect of application flexibility and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

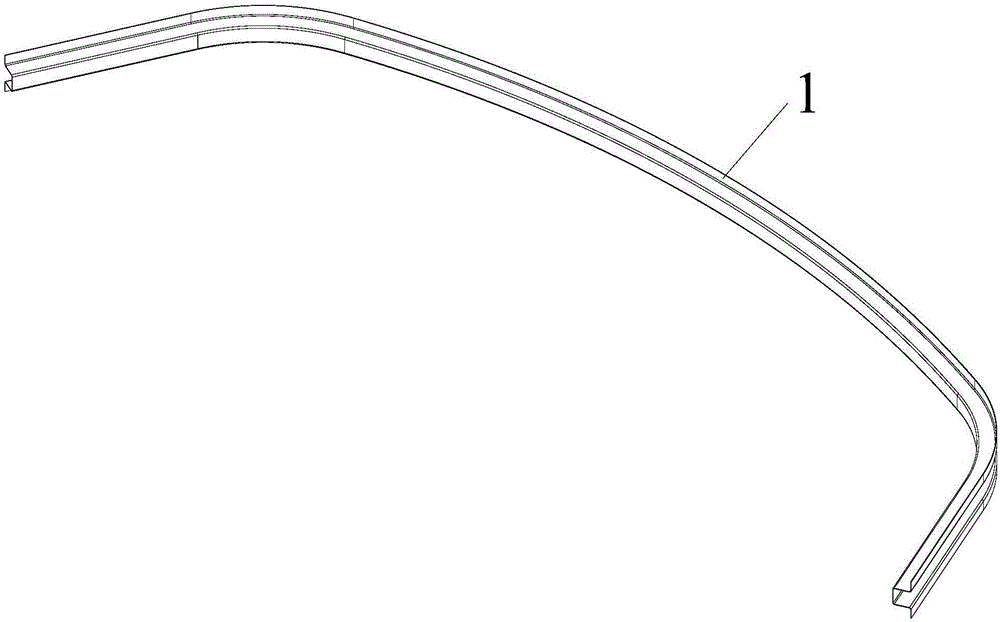

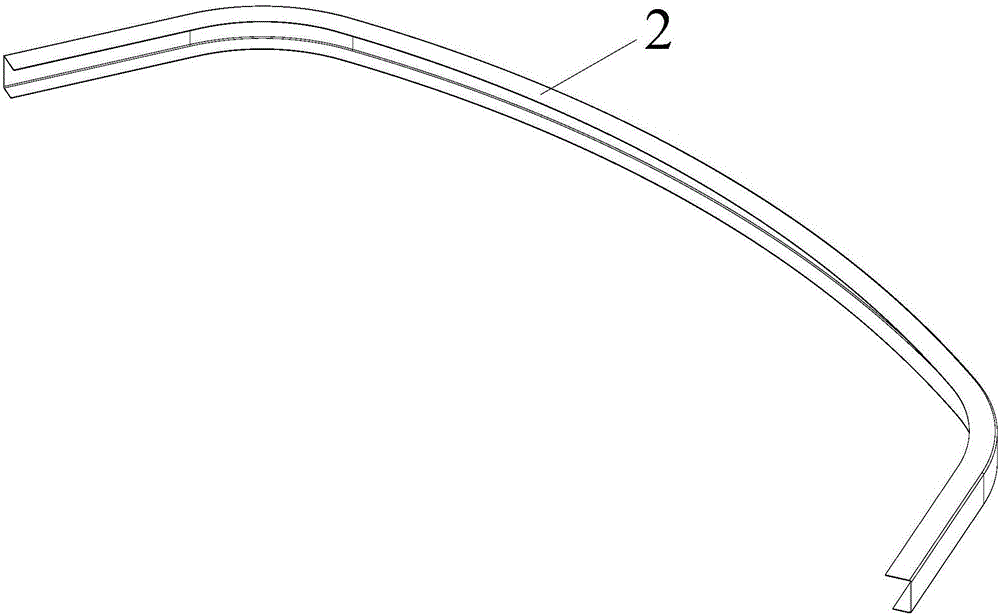

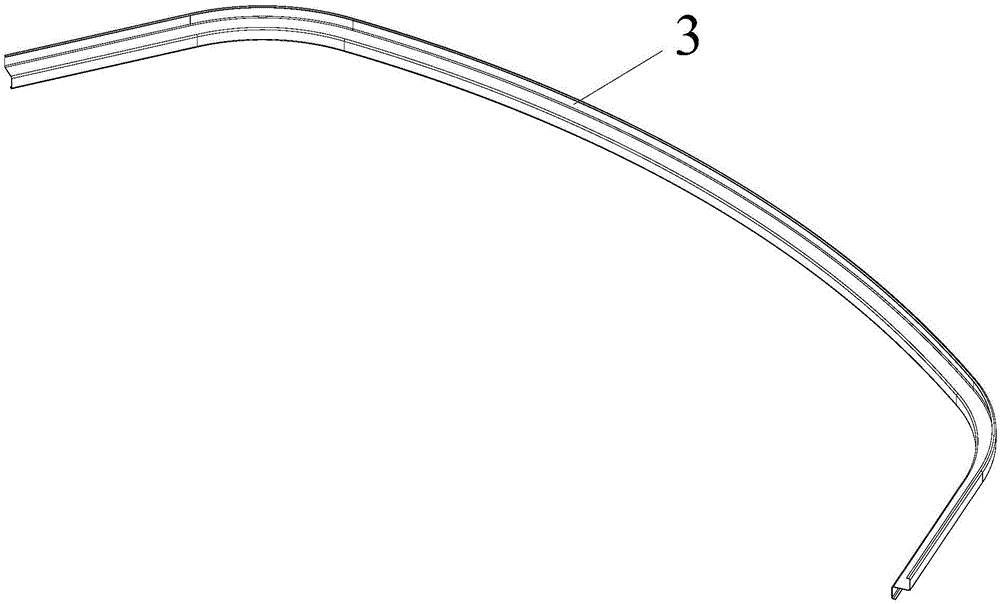

[0046] Such as Figure 8 to Figure 21 As shown, the universal fixture for the roof curved beam used in the laser cutting process of the present invention includes a curved beam outer arc surface limit mechanism 8, an end plate center support 5, two end plate side supports 4, and three transverse top supports. Tightening mechanism 6, curved beam support rail 7, six connecting plates 9 and base 10, curved beam outer arc surface limit mechanism 8 includes an arc plate 8-1, and the arc of the inner wall of arc plate 8-1 The curved surface is exactly the same as the outer arc curved surface of the roof curved beam, which is used to limit the outer arc curved surface of the roof curved beam. The center support 5 of the end plate and the side supports 4 of the two end plates are all fixedly connected to the outer end surface of the arc plate 8-1, and all three of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com