Piston, and piston copper bush installation method and installation device

A technology for installing equipment and copper sleeves, which is applied to pistons, mechanical equipment, metal processing equipment, etc., can solve the problems of cylinder liner damage, copper sleeve falling off, cylinder engine scrapping, etc., and achieves convenient and accurate installation, unique structure, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

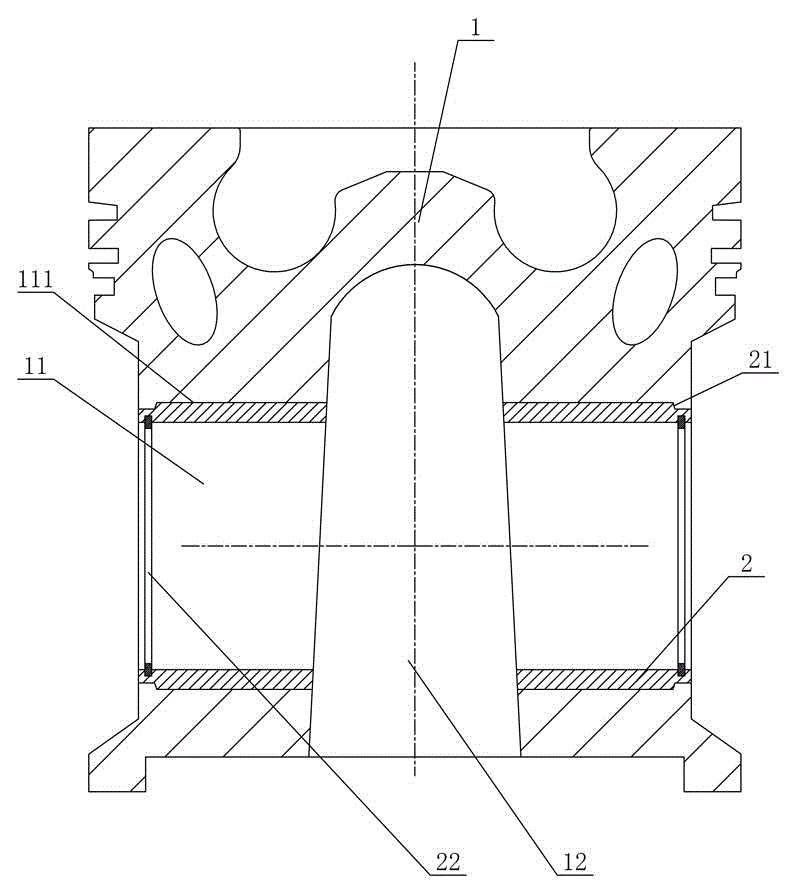

[0040] Such as figure 1 As shown, the embodiment of the piston of the present invention, the piston includes a piston body 1 and a copper sleeve 2, the pin seat of the piston body 1 is provided with a pin seat hole 11 penetrating, and a pin seat opening is provided between the two pin seat holes 11. Crotch 12, the outer circle of copper sleeve 2 is provided with card table 21, and pin seat hole 11 is provided with card groove 111 near pin seat opening crotch 12, and copper sleeve 2 is inserted into pin seat hole 11 after pin seat opening crotch 12 ends The card table 21 is engaged with the card slot 111 , and the outer circle of the copper sleeve 2 is in interference fit with the inner wall of the pin seat hole 11 . In this structure, through the engagement of the card table 21 and the card groove 111, the pin seat hole 11 itself can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com