Healthcare wooden photo frame manufacturing method

A manufacturing method and technology of photo frames, which are applied in the manufacture of tools, picture frames, wood stamping, etc., can solve the problems of photo frames without health care functions, and achieve the effects of improving human health, preventing age loss, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A manufacturing method of a health-care wooden photo frame, the manufacturing method of the health-care wooden photo frame comprises the following steps:

[0020] S1, selection of raw materials: select trees with health care effects, such as camphor wood, and peel the raw materials and polish them so that there are no larger protrusions or grooves on the surface of the material (the protrusions or grooves do not exceed 1mm);

[0021] S2, anti-discoloration pre-soaking: soak 5-10d with the mixed solution of sodium bicarbonate 0.225% and caustic soda 0.02% (the higher the temperature of the aqueous solution, the shorter the soaking time, the lower the soaking time of the aqueous solution, the longer), and then use Rinse with clean water 2-3 times;

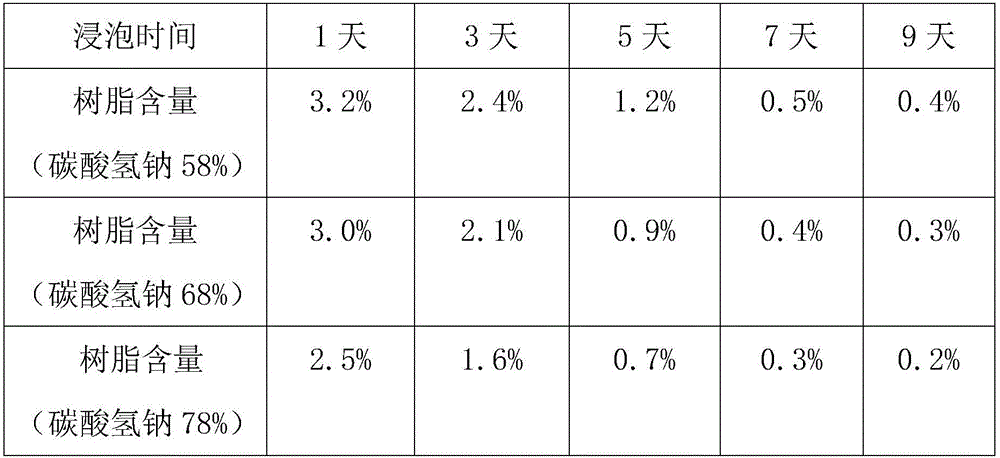

[0022] S3, anti-mildew, anti-blueing pre-soaking: use DDAC (dimethyl didecyl ammonium chloride) and inert latex (as a binder) to cooperate, put the raw materials into the mixture and soak for 1-2 weeks, and the medicament Can...

Embodiment 2

[0033] A manufacturing method of a health-care wooden photo frame, the manufacturing method of the health-care wooden photo frame comprises the following steps:

[0034] S1. Raw material selection: choose trees with health care effects, fir and peel the raw materials and polish them so that there are no large protrusions or grooves on the surface of the material (the protrusions or grooves do not exceed 1mm);

[0035] S2, anti-discoloration pre-soaking: soak 5-10d with the mixed solution of sodium bicarbonate 0.225% and caustic soda 0.02% (the higher the temperature of the aqueous solution, the shorter the soaking time, the lower the soaking time of the aqueous solution, the longer), and then use Rinse with clean water 2-3 times;

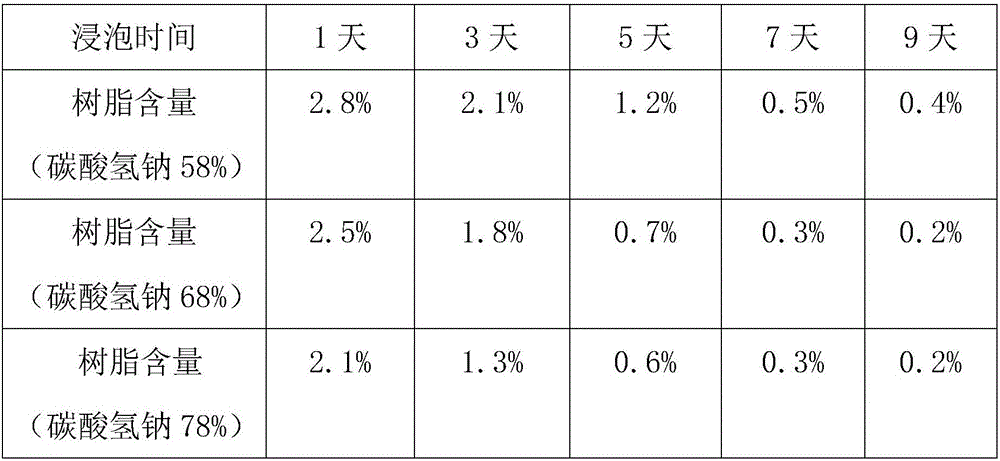

[0036] S3, anti-mildew, anti-blueing pre-soaking: use DDAC (dimethyl didecyl ammonium chloride) and inert latex (as a binder) to cooperate, put the raw materials into the mixture and soak for 1-2 weeks, and the medicament Can penetrate into wood, e...

Embodiment 3

[0047] A manufacturing method of a health-care wooden photo frame, the manufacturing method of the health-care wooden photo frame comprises the following steps:

[0048] S1. Selection of raw materials: choose trees with health care effects, such as sandalwood, and peel the raw materials, and polish them flat, so that there are no large protrusions or grooves on the surface of the material (the protrusions or grooves do not exceed 1mm);

[0049] S2, anti-discoloration pre-soaking: soak 5-10d with the mixed solution of sodium bicarbonate 0.225% and caustic soda 0.02% (the higher the temperature of the aqueous solution is, the shorter the soaking time is, the lower the soaking time is the longer the temperature of the aqueous solution), and then use Rinse with clean water 2-3 times;

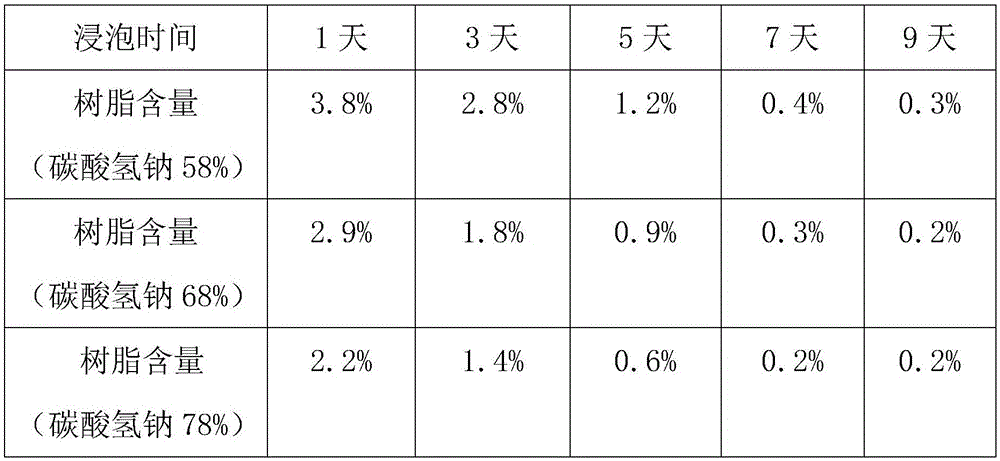

[0050] S3, anti-mildew, anti-blueing pre-soaking: use DDAC (dimethyl didecyl ammonium chloride) and inert latex (as a binder) to cooperate, put the raw materials into the mixture and soak for 1-2 week...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com