Simple and efficient method for preparing salty peptide from wheat protein

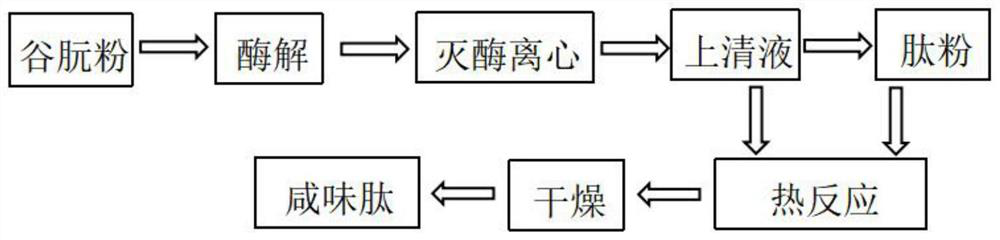

A wheat protein and wheat peptide technology, applied in food science and other directions, can solve the problems of complex preparation process and many by-products of salty peptides, and achieve the effect of improving product flavor, easy absorption and prominent salty taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A simple and efficient method for preparing wheat protein salty peptides, the steps are as follows:

[0034] (1) Proteolysis: prepare a 5% (w / v, g / ml, the same below) gluten aqueous solution, stir to form a uniform suspension, add flavored protease (Novozymes), and the ratio of protease to substrate is 3500U, 50 ℃ enzymatic hydrolysis 3h. After the enzymatic hydrolysis, the enzyme was boiled for 10 min to kill the enzyme, centrifuged at 3500 rpm for 15 min, and the supernatant was spray-dried to obtain wheat peptide powder.

[0035] (2) Heat treatment: make the peptide powder in step 1 into a 5% (w / v, the same below) aqueous solution, add 10% arginine by mass of the peptide powder, heat treatment at 110°C for 2 hours, and then drop to room temperature after the reaction is complete , the salty peptide was obtained after spray drying.

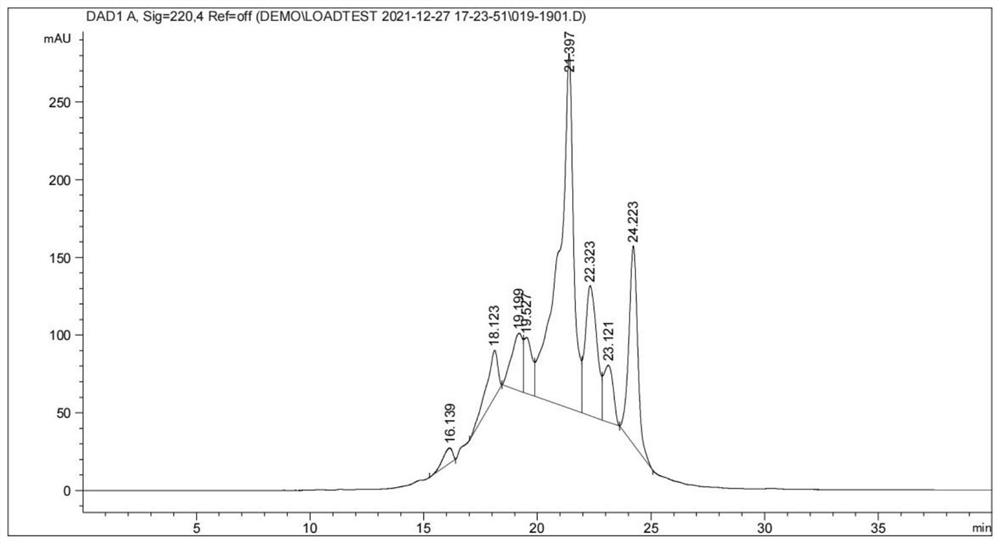

[0036] The salty taste evaluation of the peptide powder in step (1) and the salty peptide obtained in step (2) is as follows:

[0037...

Embodiment 2

[0044] A simple and efficient method for preparing wheat protein salty peptides, the steps are as follows:

[0045] (1) Proteolysis: prepare a 5% gluten aqueous solution, stir to form a uniform suspension, add flavored protease (Novozymes), and the ratio to the substrate is 3500U, and the enzyme is hydrolyzed at 50°C for 5h. After the enzymatic hydrolysis, the enzyme was boiled for 10 min to kill the enzyme, centrifuged at 3500 rpm for 15 min, and the supernatant was spray-dried to obtain wheat peptide powder.

[0046] (2) Heat treatment: compound the peptide powder in step 1 into a 5% aqueous solution, add 8% arginine by mass of the peptide powder, heat treatment at 90° C. for 4 h, after the reaction is completed, it is lowered to room temperature, and the salty peptide is obtained after spray drying.

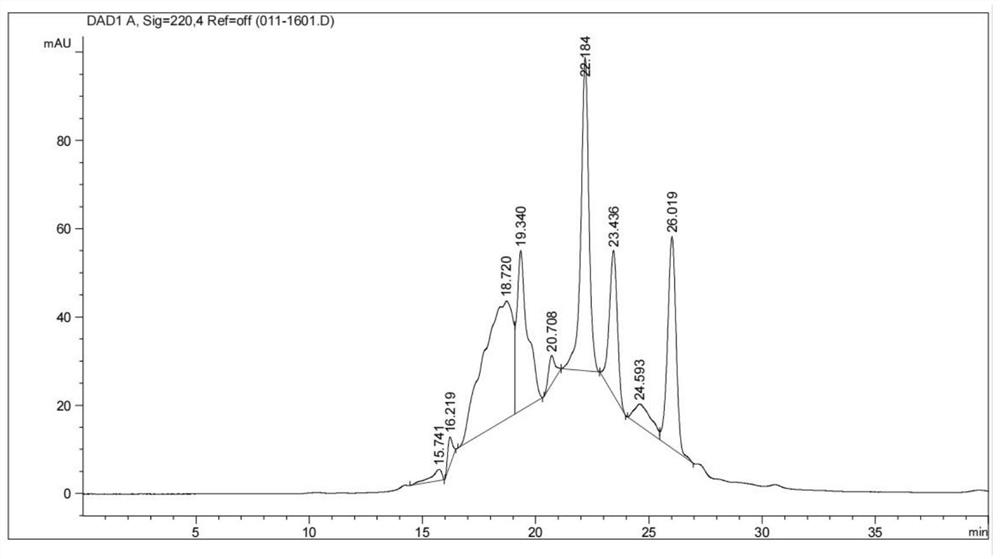

[0047] The salty taste evaluation of peptide powder in step (1) and salty peptide in step (2) is as follows:

[0048] Salty evaluation Sensory evaluation electr...

Embodiment 3

[0051] A simple and efficient method for preparing wheat protein salty peptides, the steps are as follows:

[0052] (1) Proteolysis: prepare a 5% gluten aqueous solution, stir to form a uniform suspension, add flavored protease (Novozymes), and the ratio to the substrate is 3500U, and the enzyme is hydrolyzed at 50°C for 5h. After the enzymatic hydrolysis, the enzyme was boiled for 10 min to kill the enzyme, centrifuged at 3500 rpm for 15 min, and the supernatant was spray-dried to obtain the peptide powder.

[0053] (2) Heat treatment: The above peptide powder was prepared into a 5% aqueous solution, 10% arginine by mass of the peptide powder was added, heat treated at 110° C. for 2 hours, cooled to room temperature after the reaction, and spray-dried to obtain a salty peptide.

[0054] The salty taste evaluation of peptide powder in step (1) and salty peptide in step (2) is as follows:

[0055]

[0056]

[0057] In step (1), the degree of hydrolysis of gluten is 41.62...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com