Method for improving heating oven performance of hard PVC-U pipes

A technology of PVC-U and hot oven, which is applied in the direction of household components, household appliances, and other household appliances, etc. It can solve problems such as unsatisfactory bonding strength of welded joints, unqualified hot oven tests, and stress concentration in gates, etc., to achieve Improve the performance of the thermal oven, increase the pass rate of the thermal oven test, and reduce the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

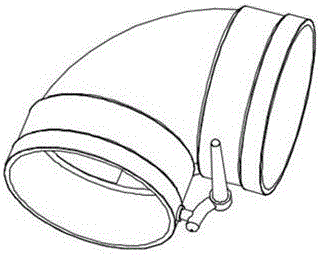

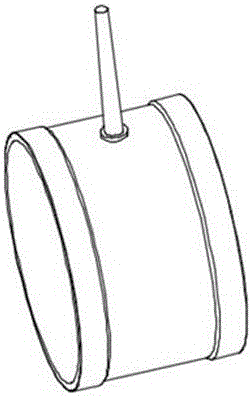

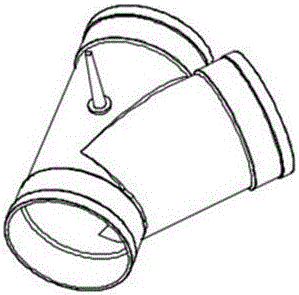

[0019] A method for improving the thermal oven performance of rigid PVC-U pipe fittings, which is used to reduce stress concentration at the gate and improve the product strength of rigid PVC-U pipe fittings. A ring-shaped reinforcing rib is arranged at the mouth, the height of the reinforcing rib is ≤5mm, and the outer diameter of the reinforcing rib is larger than the outer diameter of the gate and not greater than 1.1 times the outer diameter of the gate. Let the outer diameter of the rib be A, and the outer diameter of the gate be B, then B<A<B×1.1.

[0020] The outer diameter of the rigid PVC-U pipe fitting is ≧160mm.

[0021] The gate glue feeding method is a straight gate glue feeding method or an inclined gate glue feeding method.

[0022] The present invention improves the structure of the mold, and the ribs have the following benefits: 1. Reduce stress concentration at the gate and improve product strength; 2. Effectively prevent cold material from entering the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com