Power-failure-free AMT electric driving structure

A technology of power interruption and electric drive, which is applied in the direction of power device, electric power device, transmission device control, etc., can solve the problems affecting ride comfort and riding comfort, the specific power reduction of the electric drive system, power waste, etc., to eliminate Effects of torsional vibration hazard, volume and mass reduction, and fault tolerance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This embodiment is only a preferred technical solution, and the composition and connection relationship of the various components involved are not limited to the following implementation described in this embodiment. The arrangement and connection relationship of the various components in the preferred solution Arbitrary permutations and combinations can be performed to form a complete technical solution.

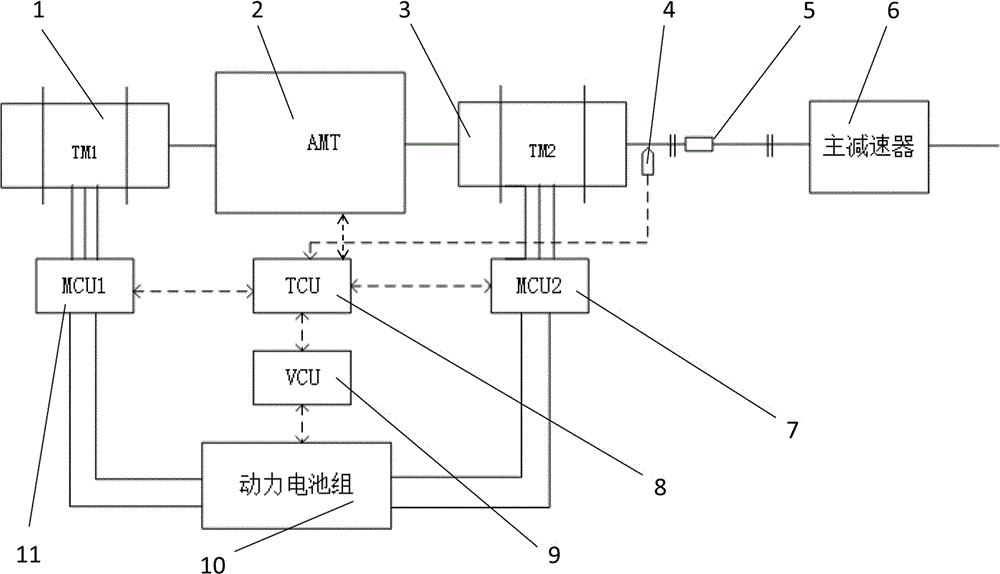

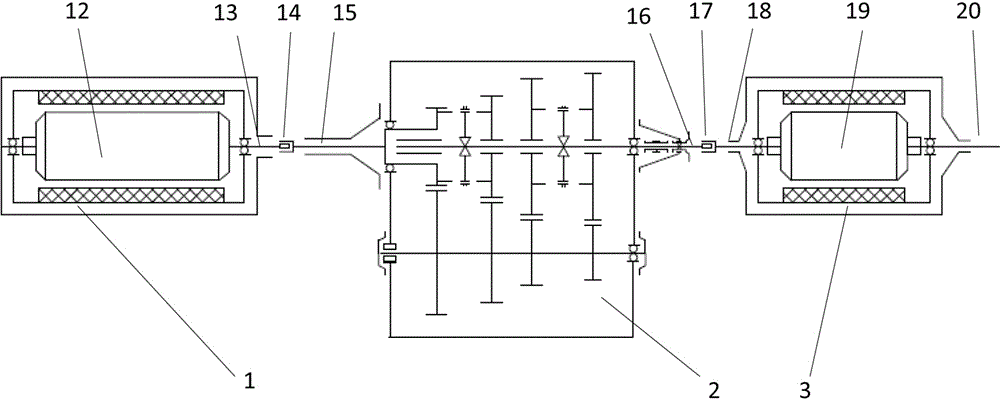

[0024] The present invention improves the existing AMT electric transmission structure, transforms the existing single-motor transmission structure into a dual-motor power coupling output structure, and the sum of the peak power of the dual motors is approximately equal to the peak power of the corresponding single motor and the sum of the peak torque of the dual motors is approximately equal to the peak torque of the corresponding single motor, the power coupling structure is the torque coupling structure. The dual motors are respectively defined as a drive motor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com