Device for preventing water outlet of biochemical tank from being blocked by MBBR (Moving Bed Biofilm Reactor) filling

A technology of water outlet and biochemical pool is applied in the field of devices for preventing MBBR feeding from blocking the water outlet in biochemical treatment sewage pools, which can solve the problems of MBBR feeding blocking the water outlet of the biochemical pool, etc., and achieves a simple structure, simple operation and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and embodiments.

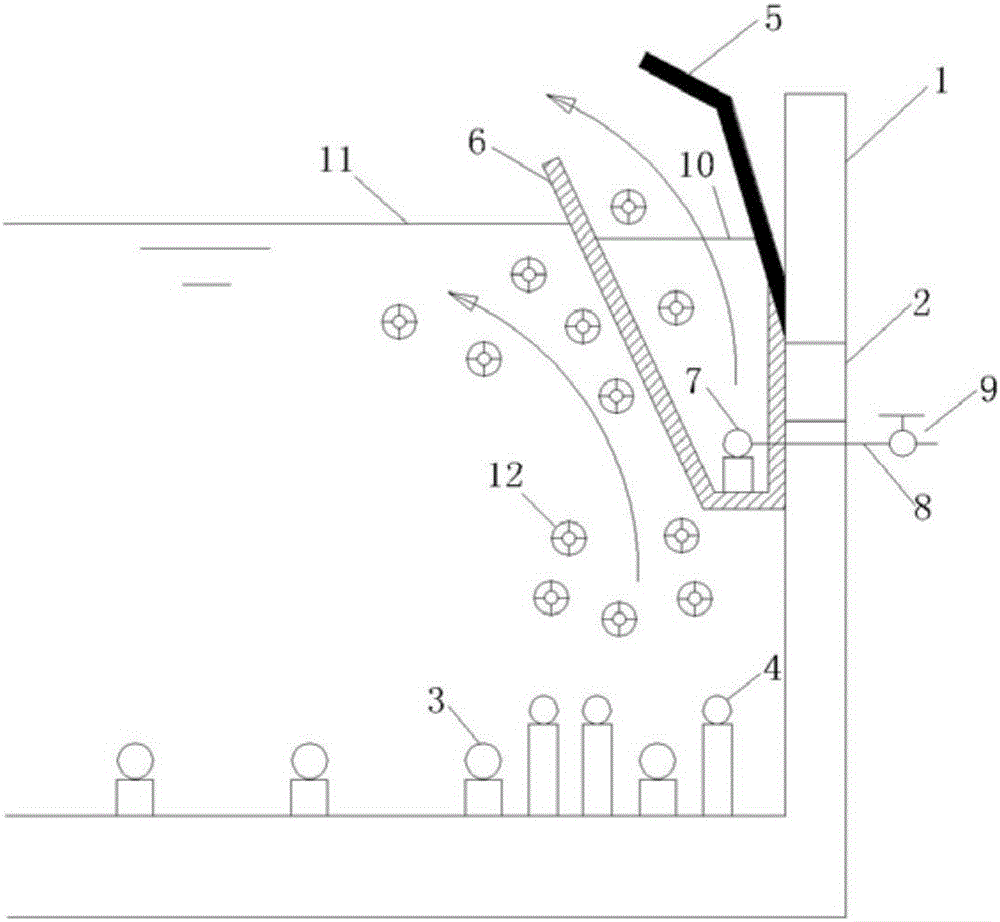

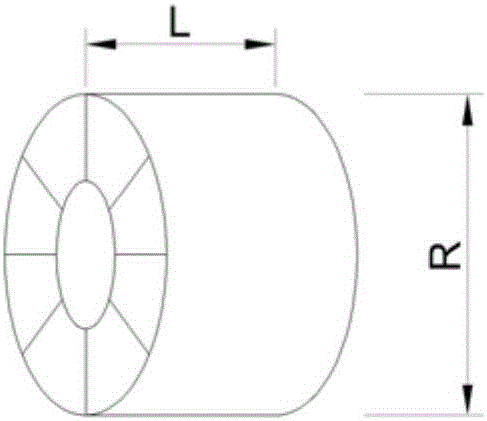

[0024] figure 1 It is a schematic diagram of the structure of a certain biochemical pond adopting the present invention. The sewage treated by the biochemical tank is domestic sewage. The length, width, and height of the biochemical tank are calculated according to the scale of sewage treatment and water quality. There is an outlet 2 on the wall 1 of the biochemical tank at one end, and the outlet is side length. 300-1000mm round hole. The added MBBR material is a polymer material with a density of 0.99, and its shape is figure 2 As shown, they are hollow cylindrical particles, and the length L and outer diameter R of the particles are both 10 mm. The design water level of the biochemical pool is 500mm from the bottom of the pool.

[0025] Such as figure 1 As shown, the device of the present invention used in the biochemical tank includes a water outlet screen 6 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com