Sucker rod centralizer facilitating decomposing resistance

A sucker rod and centralizer technology, which is applied to drill pipes, drilling equipment, earthwork drilling, etc., can solve the problems of short service life of the centralizer, inability to eliminate the resistance of the centralizer, easy damage to the sucker rod, etc. Long service life, low cost, the effect of eliminating vertical force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

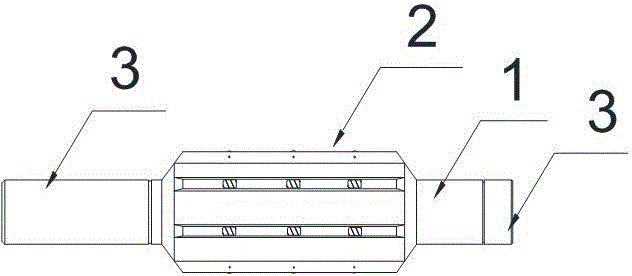

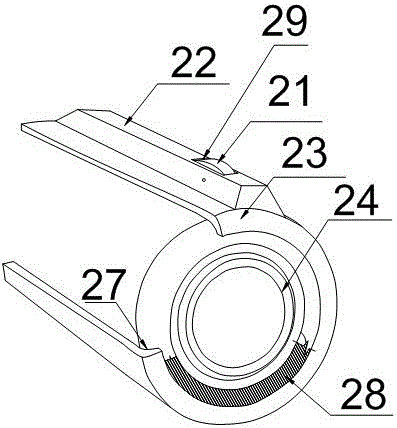

[0018] Such as figure 1 and figure 2 As shown, the sucker rod centralizer that is convenient for decomposing resistance includes a core body 1, the two ends of the core body 1 are respectively provided with interfaces 3, and the central part of the core body 1 is provided with a centralizer 2; The end sucker rods are connected, and the centralizing blocks 22 are evenly distributed along the circumferential direction of the outer cylinder 23 . Both ends of the outer cylinder 23 are provided with limiting grooves 27 , and the cover plate 28 is located between the outer cylinder 23 and the inner cylinder 24 and embedded in the limiting grooves 27 . In this embodiment, the number of cover plates 28 is two, and the two cover plates 28 are respectively arranged at both ends of the centralizer 2 . Since the outer diameter of the centralizer is larger than the outer diameter of the sucker rod, the centralizer plays a role of stabilizing the central point of the sucker rod. As the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com