Aeroengine main combustion chamber based on plasma jet ignition and combustion

An aero-engine and plasma technology, which is applied in the direction of rocket engine devices, engine ignition, engine components, etc., can solve the problem of no igniter, integration of fuel injector and combustion chamber, large flow loss of air entering the combustion chamber, and large combustion chamber volume. and weight increase, to achieve good high-altitude ignition performance, shorten ignition delay time, and reduce volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

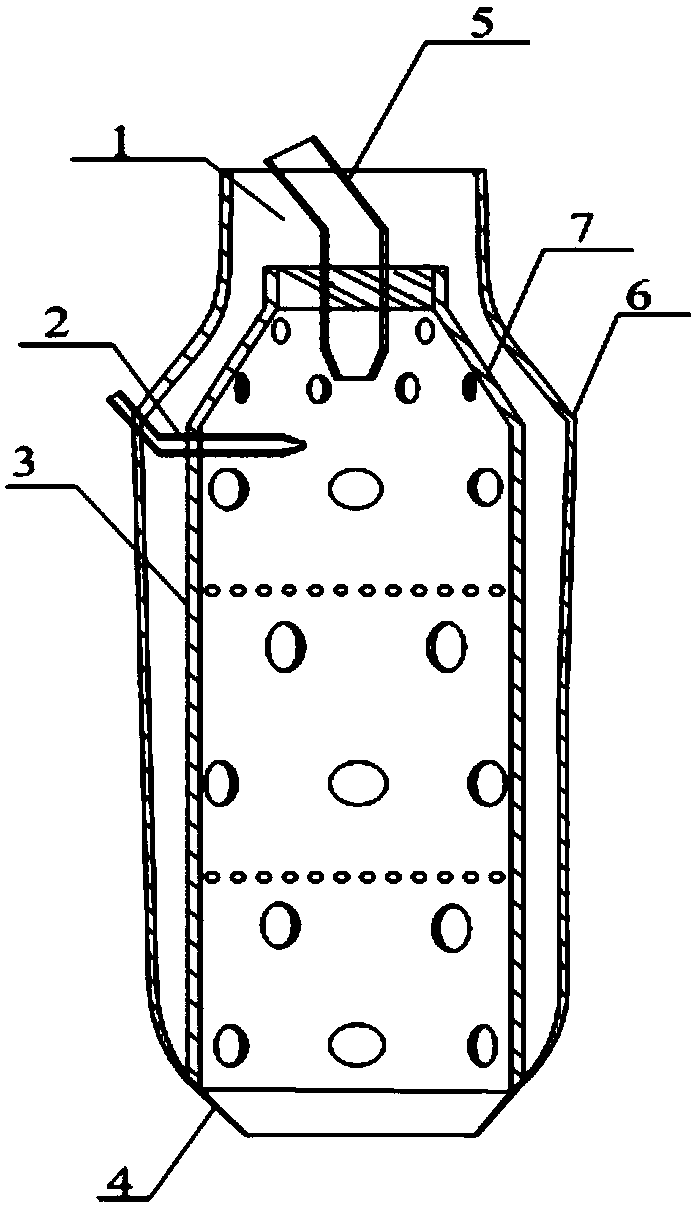

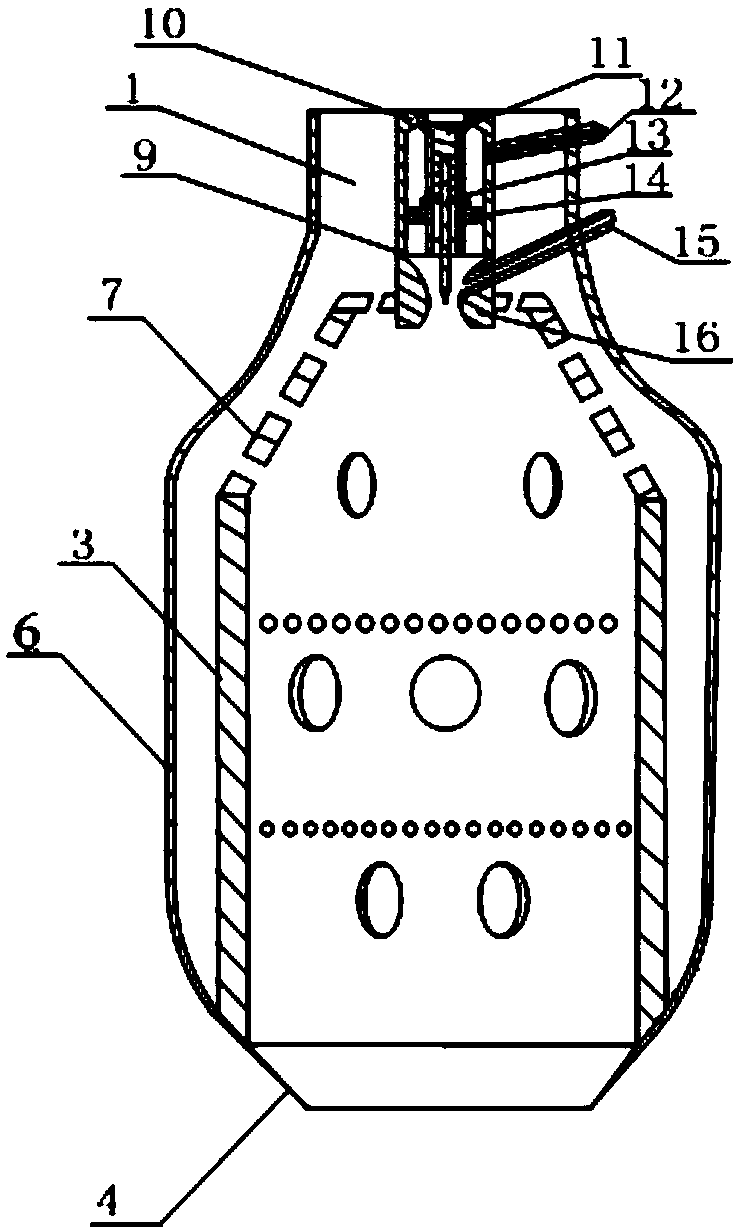

[0040] This embodiment is an aero-engine main combustion chamber based on plasma jet ignition, which is composed of three major parts: a combustion chamber 6 , a flame tube 3 , and a plasma jet igniter 9 . The flame tube 3 is located in the outer casing 6 of the combustion chamber, and the plasma jet igniter 9 is located at the upper end of the flame tube, wherein the jet outlet extends into about a third of the flame tube, and the plasma jet igniter is connected to the combustion chamber through the outer thread. entry port. The outer casing of the combustion chamber, the flame tube and the plasma jet igniter are coaxial.

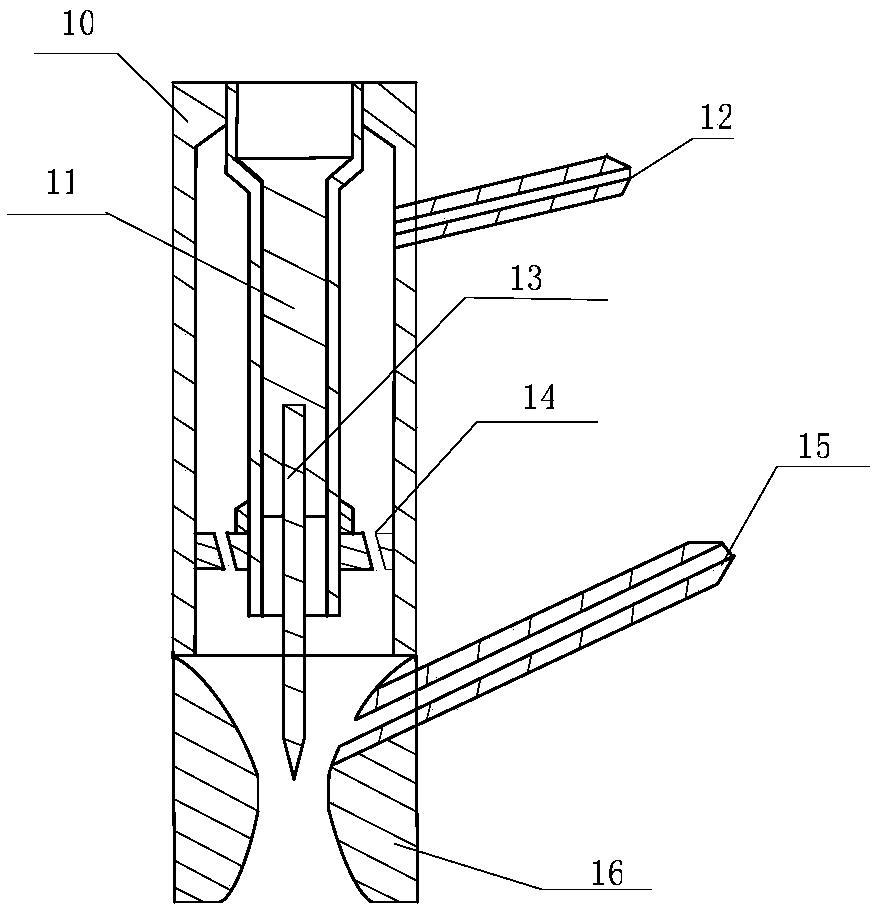

[0041] The plasma jet igniter 9 includes a head 10 , a conductive copper tube 11 , an air inlet 12 , a cathode 13 , a cyclone 14 , a fuel inlet 15 , a jet outlet 16 , an outer tube 17 , and an insulating inner tube 18 . The cathode 13 is located in the conductive copper tube 11, and the cathode 13 and the conductive copper tube 11 are connected by threads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com