Air filter

An air filter and air channel technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as lubricating oil easily clogging the filter material, lubricating oil everywhere, polluting the environment, etc. Achieve the effects of easy replacement of filter material, avoiding waste, and beautiful overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

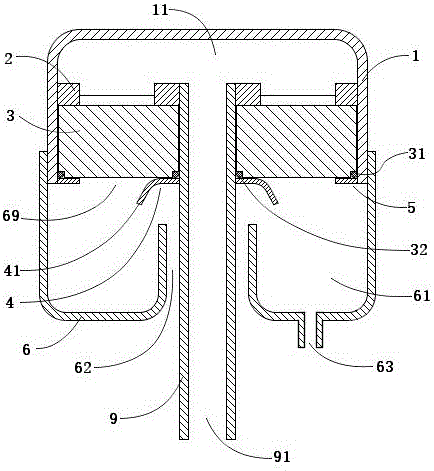

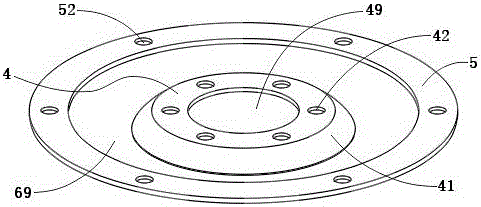

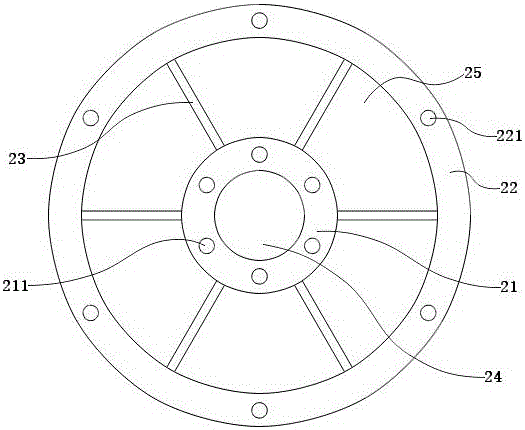

[0026] Such as figure 1 As shown, an air filter includes a cap 1 , an inner bracket 2 , a filter material 3 , an inner pressure ring 4 , an outer pressure ring 5 , an oil collecting pan 6 and a central connecting pipe 9 . The cap 1 is an inverted cup structure. Inner stent 2 as image 3 It is shown composed of an inner ring body 21 , an outer ring body 22 and spokes 23 . The inner ring body 21 and the outer ring body 22 are fixed to each other by a plurality of spokes 23, so that the inner ring body 21 and the outer ring body 22 are concentric. The spokes 23 divide the space between the inner ring body 21 and the outer ring body 22 into channels 25 for air circulation. In the center of the inner ring body 21 is the ring body central channel 24 . Screw holes 211 and screw holes 221 are respectively provided on the inner ring body 21 and the outer ring bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com