Efficient air conditioning unit with multiple refrigerant loops

A technology for refrigerant circuits and air-conditioning units, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of limiting the energy efficiency of air-conditioning units, uneven heat transfer temperature difference, waste of heat exchange area, etc., and achieves significant energy-saving effects. The effect of improving the energy efficiency of the unit and improving the energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

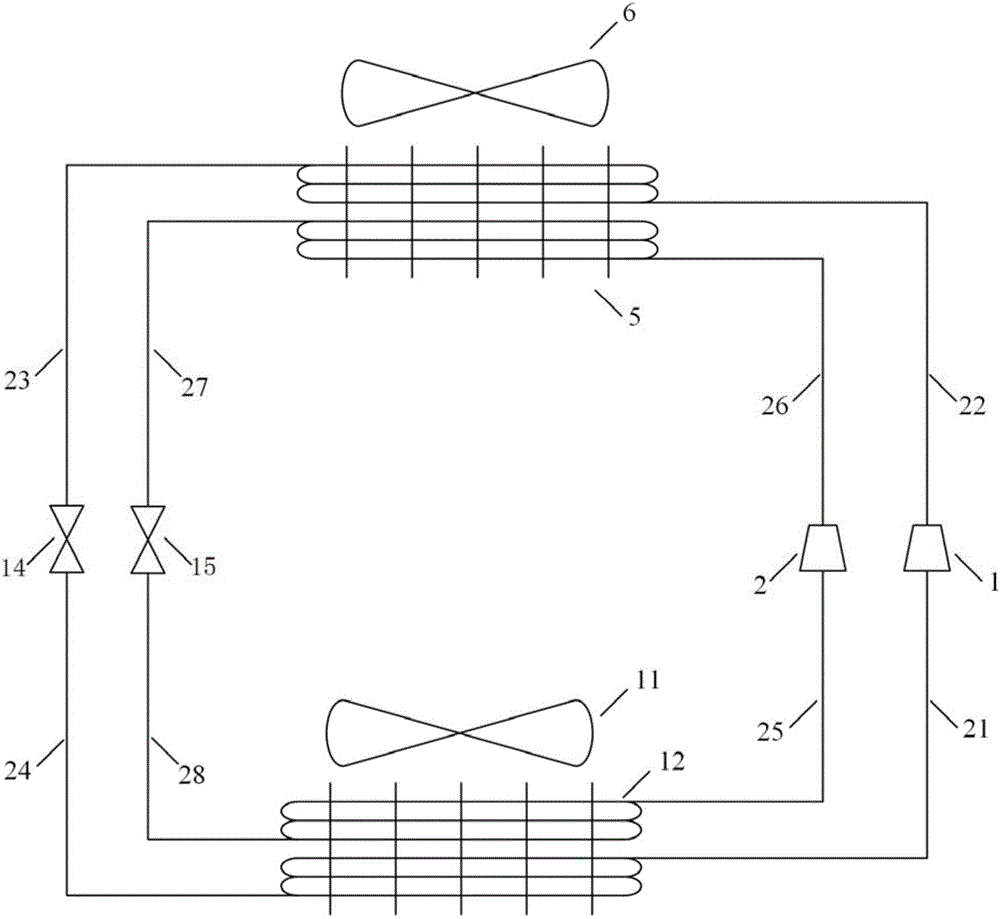

[0051] High-efficiency air conditioning units with dual refrigerant circuits such as figure 1 As shown, it includes an outdoor heat exchanger 5 with dual refrigerant flow paths, an indoor heat exchanger 12 with dual refrigerant flow paths, a first cycle compressor 1, a second cycle compressor 2, a first cycle throttling device 14, and a second cycle throttling device 14. Circulation throttling device 15, external fan 6 and blower fan 11.

[0052] The dual refrigerant flow path outdoor heat exchanger 5 has a high-temperature refrigerant channel, a low-temperature refrigerant channel, and an air channel. The two refrigerant channels are arranged forward and backward along the direction of the air channel. The low-temperature refrigerant channel is near the windward side, and the high-temperature refrigerant channel Setting near the wind outlet;

[0053] The double refrigerant flow path indoor heat exchanger 12 has a high temperature refrigerant channel, a low temperature refrig...

Embodiment 2

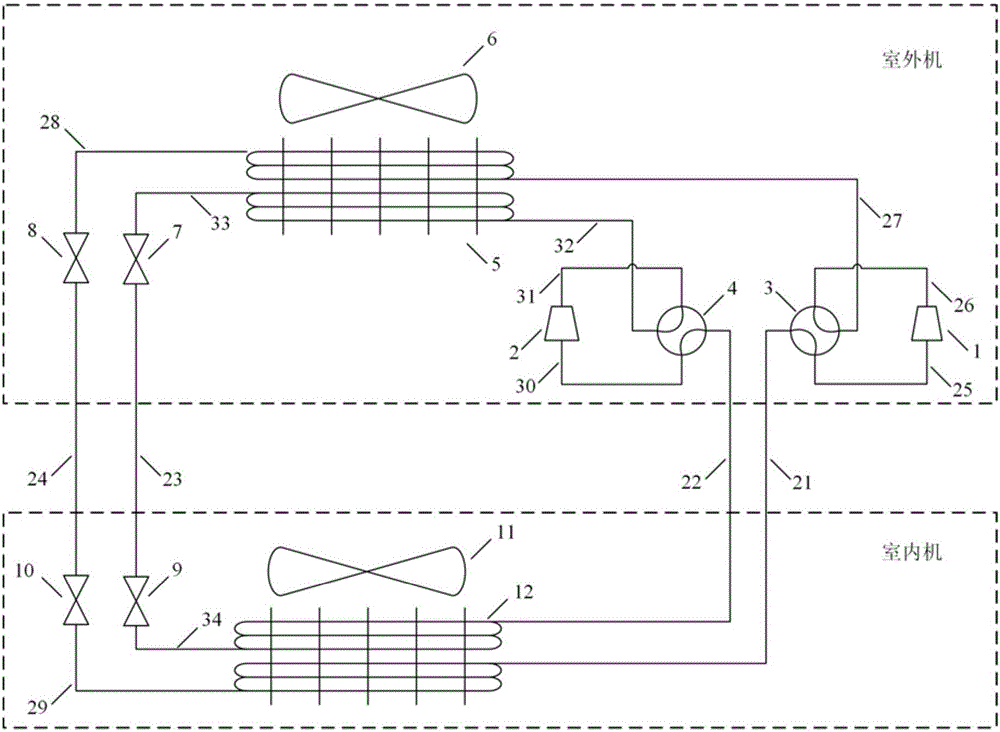

[0070] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is:

[0071] In this embodiment, the high-efficiency air-conditioning unit with dual refrigerant circuits also includes a four-way reversing valve 3 for the first cycle and a four-way reversing valve 4 for the second cycle, and a four-way reversing valve 3 for the first cycle and a four-way reversing valve for the first cycle The compressor 1 is connected, and the first cycle four-way reversing valve 3 is used to regulate the flow direction of the refrigerant in the first cycle, the second cycle four-way reversing valve 4 is connected with the second cycle compressor 2, and the second cycle four-way The one-way reversing valve 4 is used to regulate the flow direction of the refrigerant in the second cycle, and then, the cooling and heating working conditions are switched by controlling the four-way reversing valve 3 of the first cycle and the four-way reversing valve 4 of the second cycl...

Embodiment 3

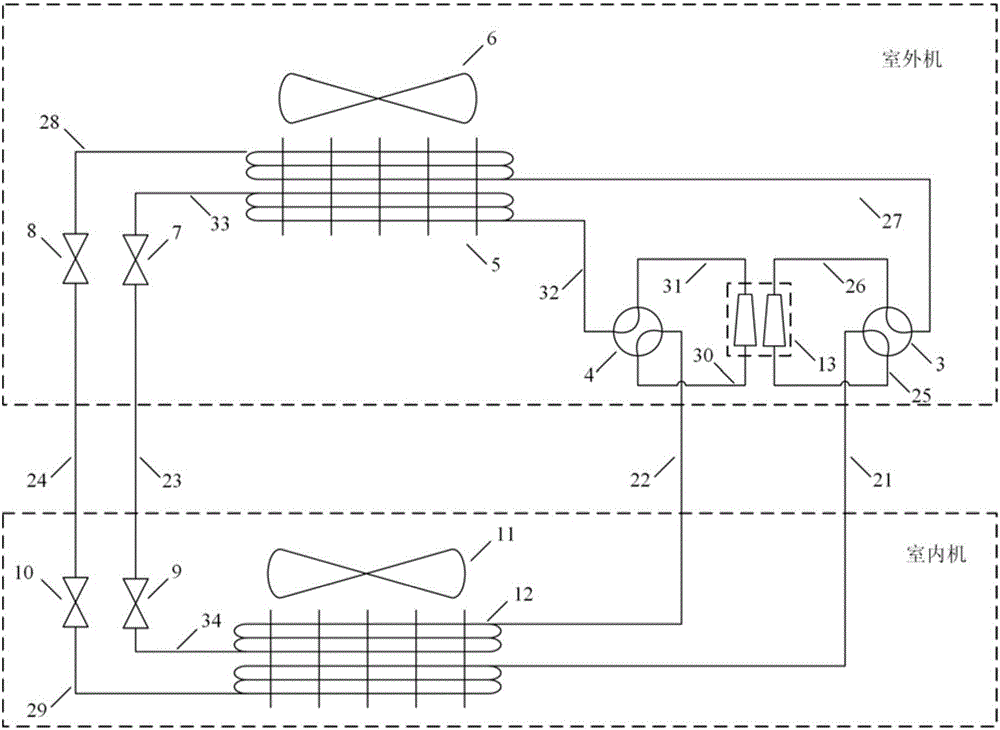

[0083] Such as image 3 As shown, the differences between this embodiment and embodiment 2 are:

[0084] In this embodiment, the first cycle compressor 1 and the second cycle compressor 2 are replaced by a double-cylinder double-suction and exhaust pressure compressor 13, and the double-cylinder double-suction and exhaust pressure compressor 13 has two Cylinder, the two cylinders have different suction pressure and exhaust pressure respectively, the cylinder connected with the first cycle is the first cycle cylinder, and the cylinder connected with the second cycle is the second cycle cylinder, the double suction and exhaust pressure of the double cylinder The compressor 13 can be a vapor compression refrigerator or a heat pump compressor.

[0085] Compared with Embodiment 2, the first circulation compressor 1 and the second circulation compressor 2 are replaced by a double-cylinder double-suction and exhaust pressure compressor 13 to simplify the system structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com